- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

depending on the model

-

Weight:

-

3000 KG

-

Application:

-

Tantalum Niobium Ore separation

-

Keywords:

-

Tantalum Niobium Ore Seperation Equipment

-

Feeding size:

-

Depending on the machine

-

Capacity:

-

According Customer Requirement

-

Installation:

-

Under Guidance

-

Recovery rate:

-

90-99%

-

Feature:

-

High Recovery Rate Easy

-

Test:

-

Client's Sample Testing

-

Product name:

-

High Return Tantalum Niobium Ore Processing Plant

-

Main products:

-

jaw crusher/impact crusher/ball mill/jigging/shaking table etc.

Quick Details

-

Production Capacity:

-

97%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

YEES

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

depending on the model

-

Weight:

-

3000 KG

-

Application:

-

Tantalum Niobium Ore separation

-

Keywords:

-

Tantalum Niobium Ore Seperation Equipment

-

Feeding size:

-

Depending on the machine

-

Capacity:

-

According Customer Requirement

-

Installation:

-

Under Guidance

-

Recovery rate:

-

90-99%

-

Feature:

-

High Recovery Rate Easy

-

Test:

-

Client's Sample Testing

-

Product name:

-

High Return Tantalum Niobium Ore Processing Plant

-

Main products:

-

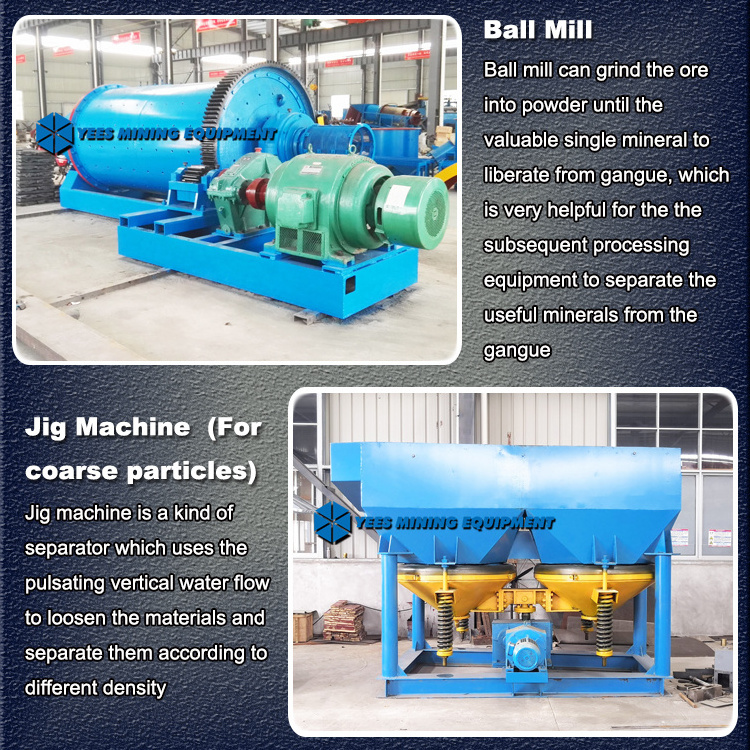

jaw crusher/impact crusher/ball mill/jigging/shaking table etc.

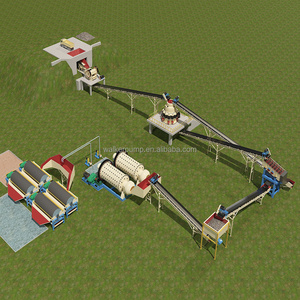

High Return Tantalum Niobium Ore Separation Equipment Tantalum Niobium Ore Processing Plant Mineral Gravity Separator

Product Description

At present, the main roughing method of tantalum niobium ore is gravity separation. Due to the low grade of tantalum niobite and the relatively high density of useful minerals, it is most suitable to use gravity separation with relatively low-cost method for roughing separation. At present, the gravity separation equipment used in tantalum niobium ore roughing includes jig machine, spiral concentrator, shaking table, centrifugal concentrator and chute, etc.

Advantages

Our Factory

Our Workshop

Our Services

Hot Searches