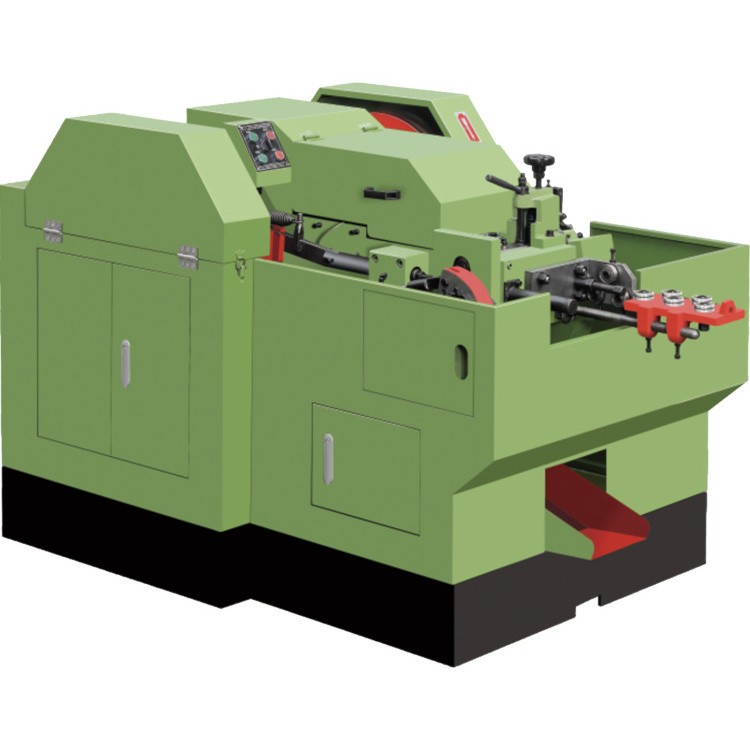

- Product Details

- {{item.text}}

Quick Details

-

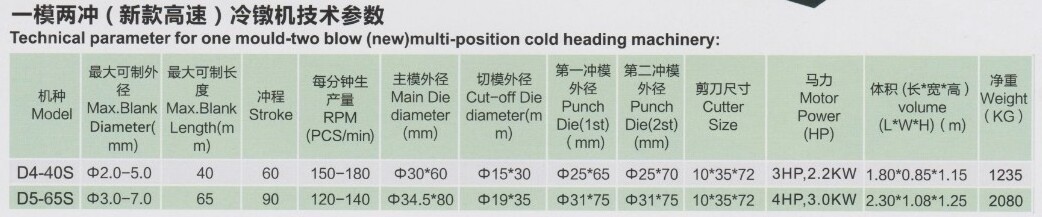

Max. Blank Diameter:

-

3-7mm

-

Max.Blank Length:

-

60mm

-

Stroke:

-

90mm

-

Capacity:

-

120-140PCS/min

-

Motor Power:

-

4HP;3KW

-

Volume(L*W*H):

-

2300*1080*1250mm

-

Weight:

-

2080KG

-

Main Die Diameter:

-

34.5*80mm

-

Cut-off Die Diameter:

-

19*35mm

-

Cutter Size:

-

10*35*72mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YUHAI

-

Weight (KG):

-

50

-

Max. Blank Diameter:

-

3-7mm

-

Max.Blank Length:

-

60mm

-

Stroke:

-

90mm

-

Capacity:

-

120-140PCS/min

-

Motor Power:

-

4HP;3KW

-

Volume(L*W*H):

-

2300*1080*1250mm

-

Weight:

-

2080KG

-

Main Die Diameter:

-

34.5*80mm

-

Cut-off Die Diameter:

-

19*35mm

-

Cutter Size:

-

10*35*72mm

Product Application

(1). The machine belong to the cold heading machine, the function is the first molding and the second punching products, which is mainly used for forming the heads of the screw products, the work principle is line materials calibration, accessing lines, sending materials to the main mold, first punching initial forging, and second punching the formed blank materials and withdraw. The work gets done without any letup, the production capacity can be up to about 150-180pcs per minute, which belongs to the more advanced products in the current technology.

(2). Upsetter various materials: Common steel, carbon steel, stainless steel, copper, aluminum, and alloy steel etc with widely functions. (For the stainless steel and alloy steel, can heat them to the appropriate temperature with the heater, and can upsetter.)

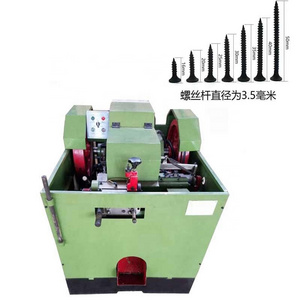

(3). The machine can make the common products such as the common self-tapping screw, electric screw, micro-screw, socket head cap bolts, self drilling screw, fiber plate screw etc. For an example PKO can upsetter other non standard abnormal hardware and metal products.

Apply:

Rivet making machine, semi-tubular rivet making machine ( Screw making machine, bolt making machine , rivet maker) being of precise and stable structure.

Main Features

1. The precise and stable structure can make precise/mini rivets with flexibility.

2. China patented united formed punch lifting plank can diminish the cumulative deviation in assembly to ensure the stability of the lifting system.

3. The flexible lifting system ensures the efficiency of the machine.

4. Slide side guide can diminish the swing of punch holder.

Brief introduction of processes and machines needed:

(1). Pull the coarse line to the line patch needed. (Wire drawing machine)

(2). Adjust, produce, and form the head of screw on the heading machine. (Screw heading machine)

(3).Grind tooth on the coil thread rolling machine, and form the screw completely (Thread rolling machine)

(4). Treat the semi-finished screw in the heat treatment according to the standard (Heat treatment furnace)

(5). According to the requirements, process plating etc. (Zinc plating machine)

(6). Packing and out of factory

Foshan nanhai district Yu Hai Screw machinery manufacturing Co.,Ltd is especial in screw machinery production for a dozen of year's. The company has excellent R & D capabilities and experience, Widely absorbed in advanced technology from Taiwan ,Japan and German and combining with modern screw industry requirement in depth, the latest processing technology is widely adopted to let us always adhered to the principle of continuous quality improvement. With the precise debugging and assembly technology, our strictly quality control ensures our products are in precious quality and stable performance.

1.Why do we choose Yuhai screw machines ?

We are professional manufacturer of various kinds of screw, nail,rivets making machines located in Foshan city of Guangdong province , Which has over 18 years experience for producing screw production line. Not only have rice experience to produce high quality machine , but also with strong technical team as basis.

2.Have you exported machine to overseas market ?

Yes . We has exported machine to Russia , Malaysia , Pakistan , India, Vietnam , Indonesia, , South Africa , etc.

3.Is there any quality warranty and after service ?

The warranty of mechanical portion of the equipment shall be a year after you received the equipment; And help buyer installation and commissioning the equipment , and free training operator.

4.If there any quality problem of your machine and spare parts , what should I do ?

within one years, if machine have any quality problem. we will repaire for free.But if damaged parts wil be replaced by offered of charge .we provide lifelong tracing service, supply equipment parts and relevant maintenance at favorable prices, and give user technical guidance free of charge.

Before sales

Our professional technical recommend the right machine,also customise special machine as customer's requirement and special parts.

Sales following

During machine production, watching the machine quality and testing machine.and take pictures or make video for customer checking.

After Sales

We will send technical to customer's factory to install and testing machines.

We have after-sell service to supply all life-time machine maintance and repairment service.

Welcome to visit our factory, we also can take you visit our client's factory that you can clear for each process. we can provide you the most advanced technology in the world.please feel free to contact us if you are interested.