- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

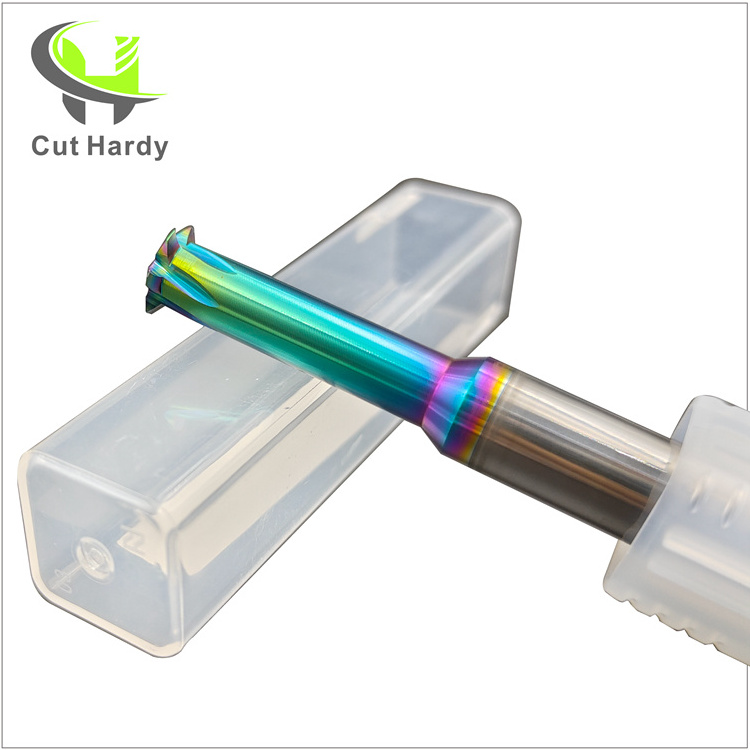

Brand Name:

-

Cut hardy

-

Model Number:

-

SE-000212

-

OEM & ODM:

-

Accpected

-

Suitable for:

-

Steel Cast Iron

Quick Details

-

Material:

-

Carbide, Tungsten Cobalt Alloy

-

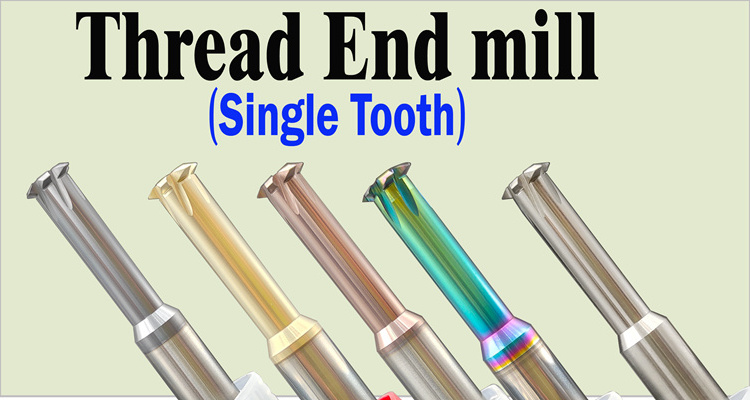

Coating:

-

AlTiN, TiAIN, TiCN

-

Warranty:

-

N

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cut hardy

-

Model Number:

-

SE-000212

-

OEM & ODM:

-

Accpected

-

Suitable for:

-

Steel Cast Iron

Key attributes

Industry-specific attributes

Industry-specific attributes

|

Material

|

Carbide

|

|

Coating

|

NONE

,AlTiN, AlTiSiN, TiN, TiAlN,

DLC

|

Other attributes

|

Place of Origin

|

Guangdong, China

|

|

Warranty

|

NONE

|

|

Customized support

|

OEM, ODM

|

|

Brand Name

|

Cut Hardy

|

|

Model Number

|

1mm to 20mm

|

|

Product Name

|

Thread End mill

|

|

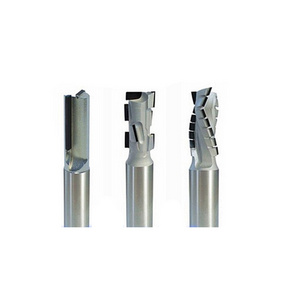

Flute

|

3/4 Flutes

|

|

Hardness

|

HRC55

/

60/65

Degrees

|

|

Material

|

Carbide, 100% New Material

|

|

Coating

|

AlTiN, AlTiSiN, TiN, TiAlN, DLC

|

|

Shank Diameter

|

1-20mm

|

|

Workpiece

|

Copper, Aluminum alloy, Alloy steel, Stainless steel, ,Cast iron,Wood

|

|

OEM

|

OEM is Hot Welcome

|

|

Free Sample

|

Available

|

|

MOQ

|

5 Pieces

|

|

Manufacture

|

we are factory

|

|

Machine

|

ROMANTIC /WALTER/ ANCA/MAKINO

|

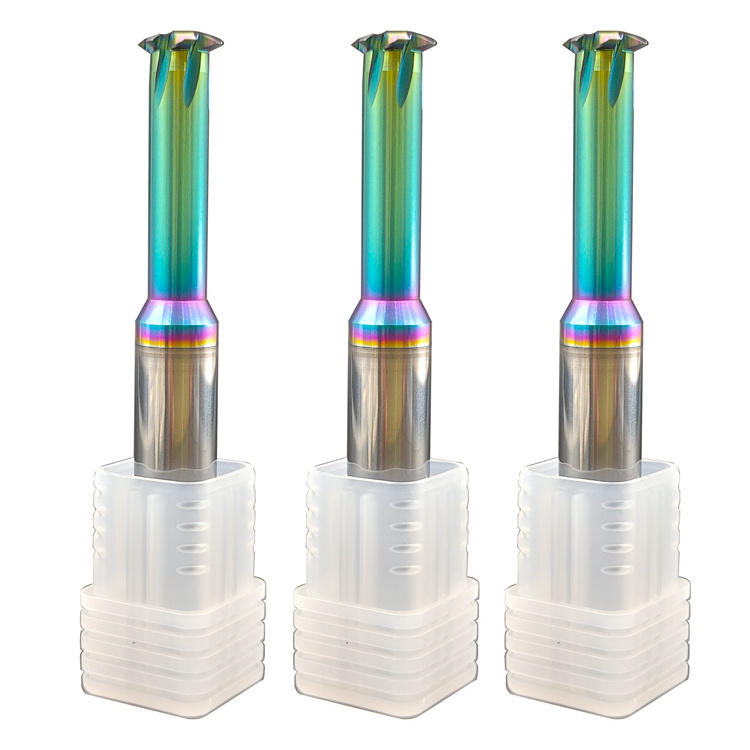

Packaging & delivery

|

Package Type:

|

1 piece in one plastic box

|

Supply Ability

|

Supply Ability

|

800000 Piece/Pieces per Month square end mill

|

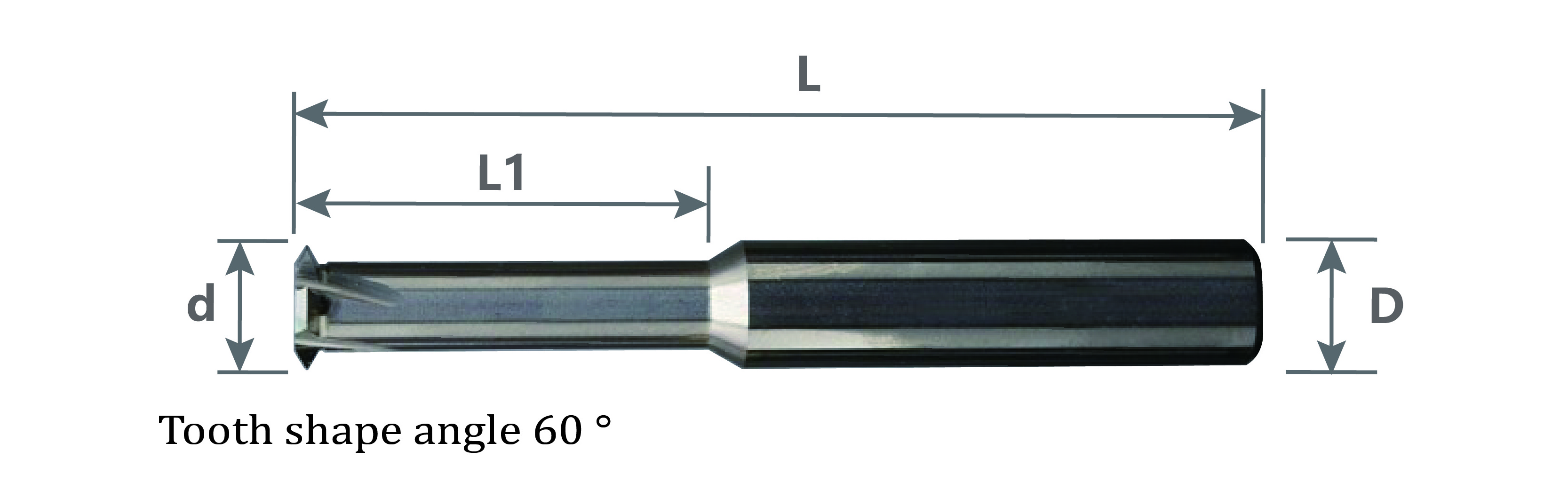

Products Description

|

Specification

|

PITCH

|

Flute dia

(d)

|

Flute length

(L1)

|

Shank Dia

(D)

|

Overall Length

(L)

|

Flutes

(F)

|

|

M0.8*0.2

|

0.2-0.225

|

0.55

|

1.6

|

4

|

50

|

3

|

|

M0.9*0.225

|

0.225-0.3

|

0.6

|

1.8

|

4

|

50

|

3

|

|

M1*0.25

|

0.25-0.35

|

0.73

|

2.3

|

4

|

50

|

3

|

|

M1.2*0.25

|

0.25-0.35

|

0.92

|

2.8

|

4

|

50

|

3

|

|

M1.4*0.3

|

0.3-0.4

|

1.05

|

3.2

|

4

|

50

|

3

|

|

M1.6*0.35

|

0.35-0.4

|

1.2

|

4

|

4

|

50

|

3

|

|

M2*0.4

|

0.4-0.5

|

1.54

|

4.4

|

4

|

50

|

3

|

|

M2.5*0.45

|

0.45-0.5

|

1.96

|

5

|

4

|

50

|

3

|

|

M3*0.5

|

0.5-0.6

|

2.4

|

7.5

|

4

|

50

|

3

|

|

M5*0.8

|

0.5-0.8

|

3

|

12

|

4

|

50

|

4

|

|

M4*0.7

|

0.5-0.8

|

3.15

|

10

|

4

|

50

|

3

|

|

M5*0.8

|

0.5-1.0

|

4

|

12

|

4

|

50

|

4

|

|

M5*0.8

|

0.5-1.0

|

4.0

|

13

|

6

|

50

|

3

|

|

M6*1.0

|

0.5-1.0

|

4.75

|

16

|

6

|

50

|

3

|

|

M8*1.25

|

0.5-1.25

|

5

|

16

|

6

|

50

|

4

|

|

M8*1.25

|

0.5-1.25

|

6.0

|

20

|

6

|

60

|

3

|

|

M10*1.5

|

0.8-1.5

|

7.9

|

25

|

8

|

60

|

4

|

|

M10*1.5

|

0.8-1.5

|

8

|

20

|

8

|

75

|

4

|

|

M12*1.5

|

1.25-2.0

|

9.4

|

28

|

10

|

75

|

4

|

|

M12*1.75

|

1.0-3.0

|

9.9

|

30

|

10

|

75

|

4

|

|

M12*2.0

|

1.25-2.0

|

10

|

28

|

10

|

75

|

4

|

|

M16*2.0

|

2.0-5.0

|

12

|

30

|

12

|

75

|

4

|

|

M16*2.0

|

1.0-5.0

|

12

|

30

|

12

|

83

|

4

|

|

M18*2.5

|

1.0-5.0

|

14

|

35

|

14

|

100

|

5

|

|

M22*3.0

|

2.0-5.0

|

16

|

40

|

16

|

100

|

5

|

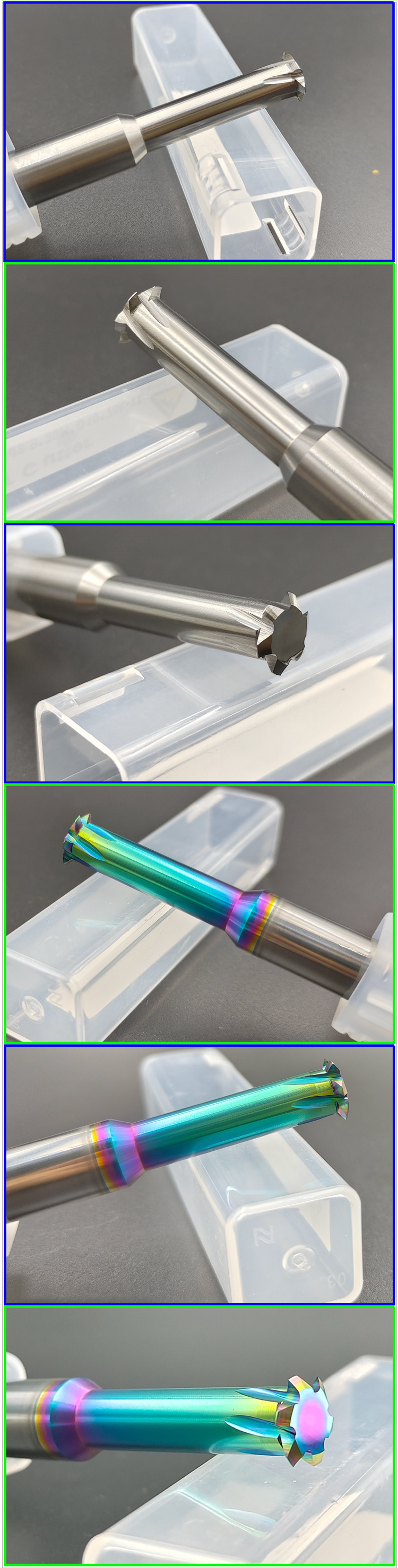

Details Images

Dongguan Chenhui precision hardware Technology Co., LTD, Cut Hardy precision Tools was established in 2008 in Tainan City,Taiwan,China, an Asian industrial base, is a high-tech enterprise specializing in the research and development, design,

manufacturing and sales of precision CNC tools. The company in line with the "quality-oriented, excellence" business philosophy toserve the world's 5 continents. With professional technical team and high precision testing equipment to ensure that each tool factory can meet the high quality requirements of customers.

We has a large number of imported high-precision equipment, grinding equipment: Germany Walter, Australia Anka, Japan Makino;Testing equipment: Germany ZOLLER, Germany Walter, Japan Keyence. Cut Hardy company mainly to milling cutter, micro end mill,thread milling cutter, drill, reamer as the core of nearly a thousand kinds of product lines, serving aerospace, petroleum geology and mining, Marine electronics, military and general machinery, automotive industry, Plastic and metal mold, medical equipment, 3C digital and other industries.

Has a complete and scientific quality management system, the use of German advanced production technology and quality control standards, has passed the ISO9001 and ISO14001 quality environment system certification. "Cut Hardy" is recognized by the industry for its integrity, strength and quality. How to create a competitive advantage for customers, reduce the cost of customers, and ensure product quality is the responsibility and pursuit of every employee of "Cut Hardy" company. le Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

manufacturing and sales of precision CNC tools. The company in line with the "quality-oriented, excellence" business philosophy toserve the world's 5 continents. With professional technical team and high precision testing equipment to ensure that each tool factory can meet the high quality requirements of customers.

We has a large number of imported high-precision equipment, grinding equipment: Germany Walter, Australia Anka, Japan Makino;Testing equipment: Germany ZOLLER, Germany Walter, Japan Keyence. Cut Hardy company mainly to milling cutter, micro end mill,thread milling cutter, drill, reamer as the core of nearly a thousand kinds of product lines, serving aerospace, petroleum geology and mining, Marine electronics, military and general machinery, automotive industry, Plastic and metal mold, medical equipment, 3C digital and other industries.

Has a complete and scientific quality management system, the use of German advanced production technology and quality control standards, has passed the ISO9001 and ISO14001 quality environment system certification. "Cut Hardy" is recognized by the industry for its integrity, strength and quality. How to create a competitive advantage for customers, reduce the cost of customers, and ensure product quality is the responsibility and pursuit of every employee of "Cut Hardy" company. le Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

|

Shipping

|

|

|

|

|

||||

|

MOQ

|

10 PCS Carbide End Mills

|

|

|

|

|

|

|

|

|

Port

|

Shenzhen

|

|

|

|

Lead Time

|

Sample,Standard Size

|

Within 3days if in stock.

|

|

|

|

|

Otherwise within 10-15days

|

|

|

|

End Mills,Non-standard Size

|

Within 7-10days if small order,

|

|

|

|

|

bulk order within 30days

|

|

FAQ

Q1:Do you produce special cutting tools?

Yes,we specialized customized cutter fabricate and translates the most complex cutting idea into reality, tools manufacturered by us are designed and customized for the right demancing applications and variety materials!

Q2:How can we know you produce the correct tools for our machining?

We make tools strictly according to your drawings,also we provide technical & engineering drawings for your confirmation before production

Q3:Do you accept low volume for sample order? and what’s your MOQ for special tools?

Yes,we do. Generally speaking,our minimum order is 5 nos or above,it can be negotiated for special requirement.

Q4:How do you guarantee the cutting tools quality?

We warranty our materials and workmanship,use the highest quality carbide and all tools are inspected strictly according to ISO certificate from the raw material to final product. key dimensions 100% checked before shipping.

Q5:If we want to work with you, is it possible to get confidentiality?

Sure, all your info include company info, drawings, PO details will be confidential, we can signed NDA if you want (non disclosure agreement)

Q6:What’s your delivery time?

It depends on the inventory availability,if items needed are in stock,it can be shipped within 24hours. but if not,usually our

delivery time is about 7days

Hot Searches