- Product Details

- {{item.text}}

Quick Details

-

Needle:

-

2

Quick Details

-

Weight (KG):

-

50

-

Place of Origin:

-

China

-

Brand Name:

-

Boway

-

Needle:

-

2

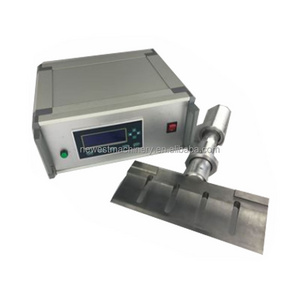

Ultrasonic knife blade vibrating at an ultrasonic frequency can easily slice through the material to be cut quickly and precisely without leaving behind any residue in the form of particles.Ultrasound has been used for years for cutting finished products. The swinging, cold cutting sonotrode reduces resistance in thecutting process and even cleans itself off residue when used with baked goods, energy bars, cheese, pizza, etc.The result: smooth, reproducible cutting surfaces without deformation and thermal damage of the product.

Product Description

Specification

|

Ultrasonic Blades Model

|

Frequency

|

Power

|

Blade Width

|

Blade Height

|

|

|

40KHz

|

500W

|

80mm

|

70mm

|

|

|

20KHz

|

800W

|

100mm

|

128mm

|

|

|

20KHz

|

1200W

|

152mm

|

258mm

|

|

|

20KHz

|

1000W

|

255mm

|

128mm

|

|

|

20KHz

|

1500W

|

305mm

|

128mm

|

|

|

20KHz

|

1600W

|

350mm

|

128mm

|

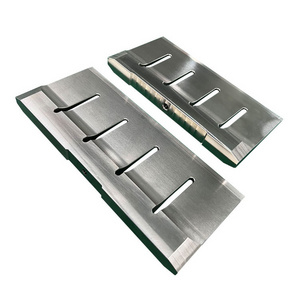

Features:

1. Ultrasonic power :0-100% adjustable

2. No sticking to the blade

3. Compact equipment with a wide range of application

4. Scalable machines adjustable according to your needs

5. Wide product variety of slicing without any blade changing

6. No diameter, weight or thickness limits

7. Easy to wash down, and easy to maintain

8. Possibility to increase the cutting width with blades in series

9. High speed slicing: 60 to 120 strokes / min

2. No sticking to the blade

3. Compact equipment with a wide range of application

4. Scalable machines adjustable according to your needs

5. Wide product variety of slicing without any blade changing

6. No diameter, weight or thickness limits

7. Easy to wash down, and easy to maintain

8. Possibility to increase the cutting width with blades in series

9. High speed slicing: 60 to 120 strokes / min

Advantages:

1. Low application of force during cutting

2. Separation with no residue left behind(self-cleaning)

3. Blade temperatures do not increase

4. No need the sharp knife and large push, no damage of food.

5. Small frictional resistance, no cutting material stick to the blade

6. Fast cutting speed, save labor cost

7. Safe operating, lower energy consumption, no noise

8. Manual operating, also used for automatic machinery operating

2. Separation with no residue left behind(self-cleaning)

3. Blade temperatures do not increase

4. No need the sharp knife and large push, no damage of food.

5. Small frictional resistance, no cutting material stick to the blade

6. Fast cutting speed, save labor cost

7. Safe operating, lower energy consumption, no noise

8. Manual operating, also used for automatic machinery operating

Application:

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches