- Product Details

- {{item.text}}

Quick Details

-

Valve Core Material:

-

Ceramic

-

Model Number:

-

FNF220510

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FEENICE

-

Name:

-

bathroom glass waterfall faucets

-

Body Material:

-

Solid Brass 59

-

Usage:

-

Basin Faucet

-

Certification:

-

ISO9001

-

Cartridge:

-

Spain Sedal

-

Water Pressure:

-

0.6-0.8MPA

-

Water Flow:

-

Mixer 12L/min

-

Type:

-

Basin Faucets

Quick Details

-

Project Solution Capability:

-

Others

-

Application:

-

Hotel, Villa, Office Building

-

Design Style:

-

Modern

-

Valve Core Material:

-

Ceramic

-

Model Number:

-

FNF220510

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FEENICE

-

Name:

-

bathroom glass waterfall faucets

-

Body Material:

-

Solid Brass 59

-

Usage:

-

Basin Faucet

-

Certification:

-

ISO9001

-

Cartridge:

-

Spain Sedal

-

Water Pressure:

-

0.6-0.8MPA

-

Water Flow:

-

Mixer 12L/min

-

Type:

-

Basin Faucets

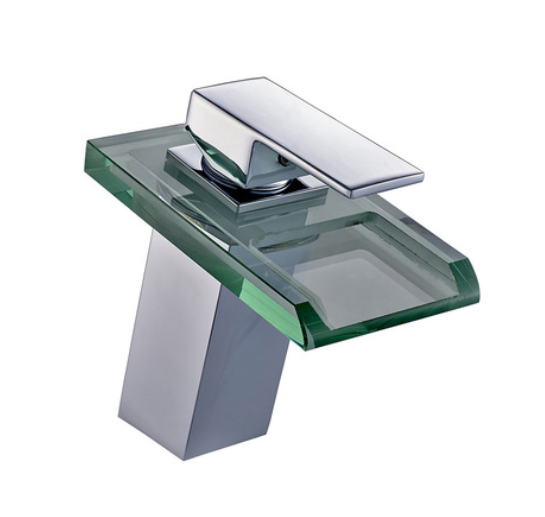

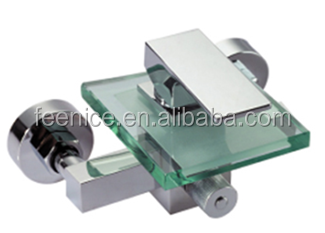

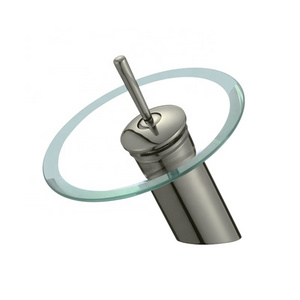

FEENICE Manufacturer brass bathroom vanity glass waterfall faucet

1.Production Name: Glass Waterfall basin mixer

2.Product Material: Brass Body,Zinc Handle

3.Brass content: 58-60%

4.Cartridge: Ceramic cartridge,

5.Cartridge Brand: Local brand,imported brand as your requirment

6.Inspection:100% inspection

7.Water test: Test every piece while assemble.

8.Delivery Time : 30 days after receipt deposit

9.Payment : T/T ,L/C at sight ,west union and so on

| Brand | FEENICE |

| Warranty | 5 years |

| Faucet Material | Brass body , Zinc handle |

| Cartridge life time | no leakage after 500000 times use |

| Surface Finishing | Chrome plated (Ni 3-12um , Cr 0.1-0.3um ),other plating like brush nickle ,antique brass ,oil rubbed etc, available |

| Air Pressure test | 0.6-0.8MPA |

| Water Pressure test | 0.6-0.8MPA |

| Testing | 120 hours salt-spray test |

| Certificate |

ISO,CE,UPC ,WATERMAKR |

1. Package:

Inner package: Cloth bag and bubble bag ,nuetral box or color box; Outer package: Export standard safe carton .

2. Shipping & Delivery

Normally 20-30days for 20GP, 30-40days for 40GP

FEENICE INSPECT IN EVERY PRODUCTION PROCEDURES TO KEEP BEST QUALITY TO CLIENTS'HANDS

1. Inspection for the casting

2. Leakage test after machining

3. Surface inspection after polishing

4. Surface inspection after plating

5. Leakage test in assembly

6. 100% insepct for the finished products