Equipped with bottle jam protection device.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

95%

-

Voltage:

-

220V, 380V, 480V, 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Dimension(L*W*H):

-

2500*1950*2300mm

-

Weight:

-

2500 KG

-

Product name:

-

Oil filling machine

-

Usage:

-

Oil, jams, daily chemicals, honey, tomato source, squish

-

Filling technology:

-

Pistion filling,positive displacement filling,volumetric filling

-

Container:

-

Glass bottle ,PET bottle, glass can ,PET can

-

Capacity:

-

1000-10000Bottle/hour (subject bottle volume)

-

Bottle volume:

-

500ml-5000ml

-

Accuracy:

-

±0.5%

-

Function:

-

Rinsing, filling, capping

-

Filling valve:

-

SUS304

-

Aftersales:

-

Online support, spare parts, field maintenance

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

95%

-

Voltage:

-

220V, 380V, 480V, 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Dimension(L*W*H):

-

2500*1950*2300mm

-

Weight:

-

2500 KG

-

Product name:

-

Oil filling machine

-

Usage:

-

Oil, jams, daily chemicals, honey, tomato source, squish

-

Filling technology:

-

Pistion filling,positive displacement filling,volumetric filling

-

Container:

-

Glass bottle ,PET bottle, glass can ,PET can

-

Capacity:

-

1000-10000Bottle/hour (subject bottle volume)

-

Bottle volume:

-

500ml-5000ml

-

Accuracy:

-

±0.5%

-

Function:

-

Rinsing, filling, capping

-

Filling valve:

-

SUS304

-

Aftersales:

-

Online support, spare parts, field maintenance

Product Description

GYH series is special for edible oil filling, capping and equipped with rotary transmission, PLC and frequency adjuster in speed. It is innovated and designed in the requirement of edible oil technics, on the bases of introducing, digesting and absorbing advanced technology. It is reasonable in structure, safe to operate and easy to maintain, which is an ideal choice for edible oil producers.

Main Features

1. Compact structured, good looking, easy to operate and highly automated.

2. Parts with contact with material are all made of stainless steel of food grade, no dead angles and easy to clean up.

3. Filling volume is controlled by measure cup or piston filling valve to ensure accurate filling.

4. Air blowing after filling to ensure no dripping.

5. Liquid buffer element specially designed inside filling valves can eliminate the cutting affection and wallop between liquid and container, easy to eliminate the air bubble in material.

6. High effective cap sorting and feed in system is protective for feed in and cap absence.

7. Equipped with overload system to safeguard machine and operators.

8. Equipped with cap absence detector and bottle jam-up detector which could stop the monoblock in that case.

9. Equipped with output calculating function for monoblock.

10. Main electronic component (touch screen, PLC and frequency inverter) are imported products.

Detailed Images

Bottle Infeed

Bottle infeed by combination of infeed screw and infeed starwheel.

Measure Cup Filling

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck.

The filling system has liquid level automatic control.

Filling valve lift is controlles by the valve elevator, after filling valve contact the bottleneck, it starts to fill.

Filling volume measured by cup with high accuracy.

Bottle is conveying by the wheel in the filling part.

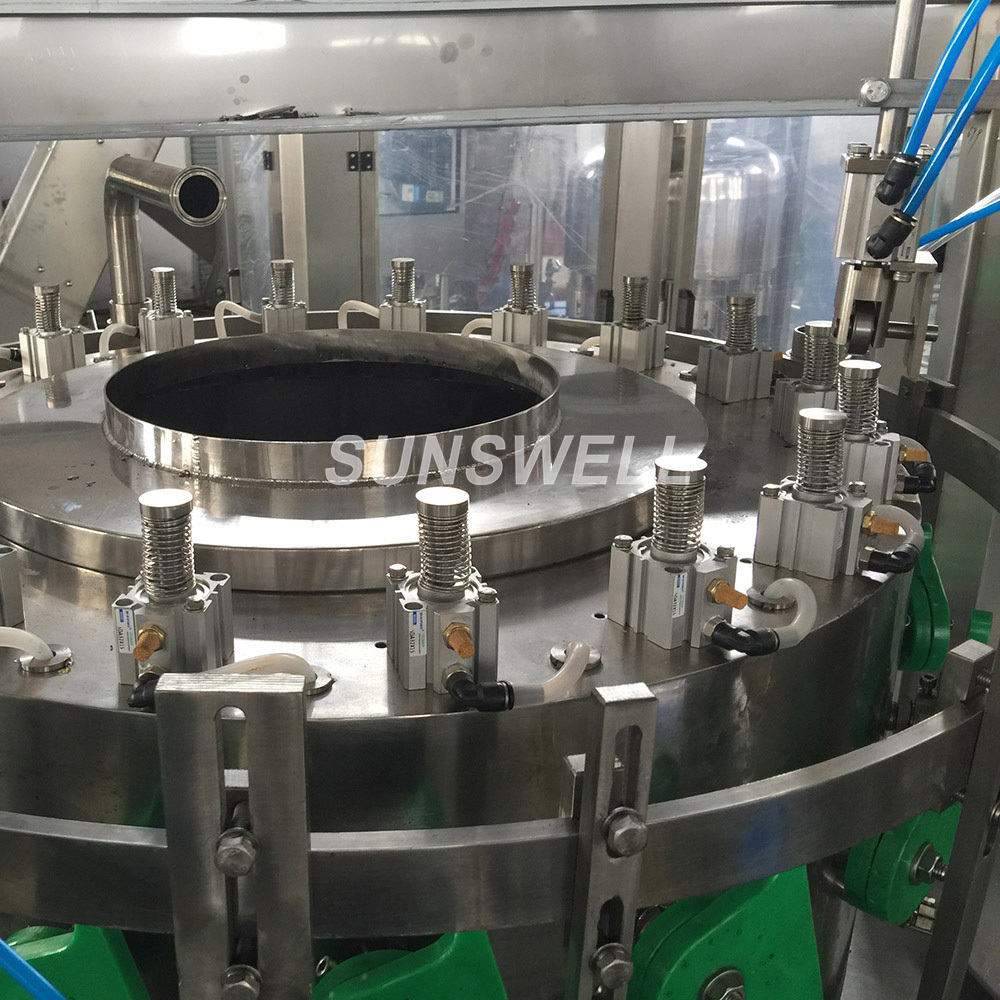

Piston Filling

Parts connect with material are all made of stainless steel SUS304, bear rust and easy cleaning.

Bottle lifting by holding bottleneck, filling nozzle inserting into bottle to ensure product not overflow the neck.

Easy to dissemble piston and rotary valve core for cleaning and sterilizing.

All product inlet part of filling valves with switch valve for stopping product feed before bottle discharge to ensure no spray of product.

Weighing Filling

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck.

The filling system has liquid level automatic control.

Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck, it starts to fill.

Conveyor Wheel Part

The material is combination of stainless steel and nylon and the wheel has block bottle protect device

ROPP Capping

Aluminum capping is composed by gear device, capping device, anti-rotate pole and elevated device. The drive is passed through transfer gear to the capper gear, and the elevated pole pass it to the capper.

Screw Capping

With highest precision, influence very much with stability and reliability of the filling monoblock.

Cap distributing chute is equipped with reserve cap stop and reserve cap pick-out mechanism.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

Equipped with inlet bottle detection switch.

Centrifugal way of cap arranging is adopted to reduce damage of caps.

A cap inspecting system is applied to control on-off of elevator.

Flip (Press-on) Capping

The capping cam is forged from 45# high quality carbon steel and is cut and machined by the machining center. In order to improve the strength of the guide rail of the cam, after the corresponding heat treatment, the surface is blacked out.

Any more questions, pls feel free to

contact me

!

Main Configuration

|

Touch screen

|

Mitsubishi/Siemens/Delta

|

|

PLC program controller

|

Mitsubishi/Siemens/Delta

|

|

Inverter

|

Mitsubishi/Siemens/Delta

|

|

Photoelectrical controller

|

Autonics

|

|

Proximity switch

|

Autonics

|

|

Other electrical components

|

Schneider/Siemens/Delixi

|

|

Pneumatic component

|

Airtac

|

|

Main motor

|

Siemens/ABB

|

Products Specification

|

Model

|

GYH12-5

|

GYH16-5

|

GYH20-5

|

GYH24-6

|

...

|

|

Filling head

|

12

|

16

|

20

|

24

|

...

|

|

Capping head

|

5

|

5

|

5

|

6

|

...

|

|

Bottle diameter (mm)

|

50-200

|

50-200

|

50-200

|

50-200

|

...

|

|

Bottle height (mm)

|

150-360

|

150-360

|

150-360

|

150-360

|

...

|

|

Air Supply Pressure (Mpa)

|

0.6-0.7

|

0.6-0.7

|

0.6-0.7

|

0.6-0.7

|

...

|

|

Air consumption (m3/min)

|

0.5

|

0.5

|

0.5

|

0.5

|

...

|

|

Motor power (KW)

|

2.57

|

3.55

|

4.56

|

5.54

|

...

|

|

Dimension (mm)

|

1600*2470*2950

|

1800*2670*2950

|

2100*267*2950

|

2400*2970*2950

|

...

|

|

Weight (kg)

|

2000

|

2200

|

2500

|

2800

|

...

|

Why Choose Us

About Sunswell:

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

Advantage:

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

(4)Serve customers over 50 countries and regions worldwide

Any more questions, please feel free to

contact us

!

Any more questions, please feel free to

contact us

!

> the wide range of liquid packaging plant machinery

> the various range of possible end products

> 10+ years of global market experience

> 80+ countries of customers worldwide

> 20+ mechanical, electrical and food science engineers

> 10+ service staff

Related Products

2. Various liquid packaging:

FAQ

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If

needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If

needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Hot Searches