- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

dong yu steel ball

-

Model Number:

-

14.288mm

-

Product name:

-

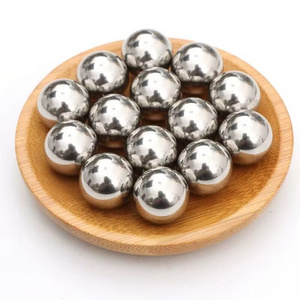

chrome steel ball

-

Name:

-

bearing steel ball

-

Size:

-

14.288MM

-

Grade:

-

G20

-

Surface:

-

High Polished

-

Application:

-

Ball Transfer

-

Hardness:

-

60-65HRC

-

Sample:

-

Small Quantity

-

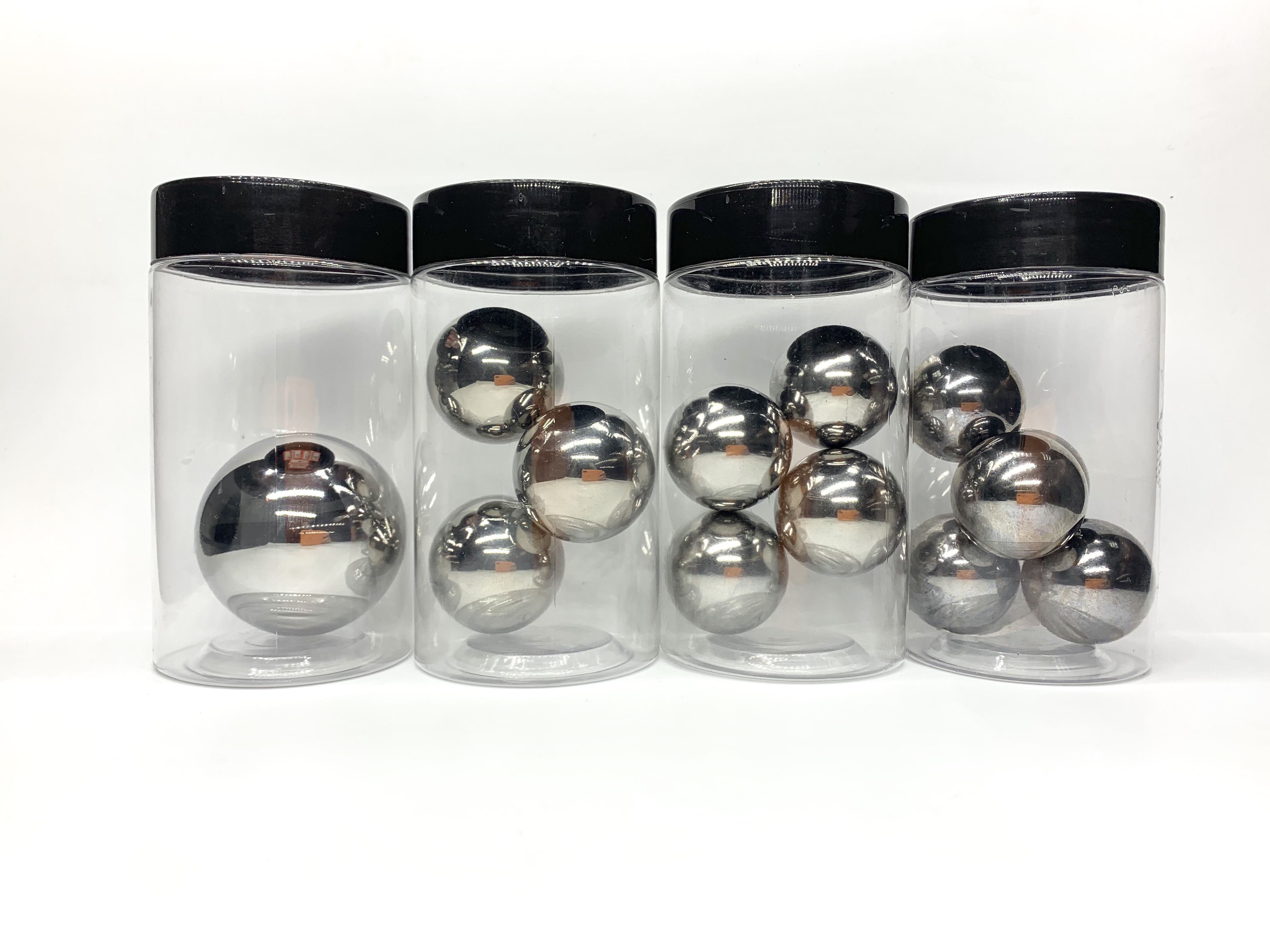

Package:

-

Plastic Bag + Cardboard Box + Wooden

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

-

Material:

-

aisi52100

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dong yu steel ball

-

Model Number:

-

14.288mm

-

Product name:

-

chrome steel ball

-

Name:

-

bearing steel ball

-

Size:

-

14.288MM

-

Grade:

-

G20

-

Surface:

-

High Polished

-

Application:

-

Ball Transfer

-

Hardness:

-

60-65HRC

-

Sample:

-

Small Quantity

-

Package:

-

Plastic Bag + Cardboard Box + Wooden

Products Description

|

0.5mm to 300mm AISI52100 GCr15 SUJ2 100Cr6 G5 to G2000 Chrome steel ball

|

|

|

|

|

|

|||||

|

Size:

|

0.5mm to 300mm

|

Grade:

|

G5 to G2000

|

Certificate:

|

Verified/ISO/TS16949

|

|||||

|

Material:

|

AISI52100/GCr15

|

Hardness:

|

HRC 60~66

|

Place of Origin:

|

Made in china

|

|||||

|

sample:

|

offer free

|

Surface:

|

Mirror Polished

|

Brand Name:

|

dong yu steel ball

|

|||||

|

Package:

|

Plastic Bag + Cardboard Box + Wooden

|

Feature:

|

Corrosion Resistance,Anti-wear

|

Standard:

|

AiSi/DIN/GB/EN/JIS/ ASTM

|

|||||

Application areas:

Chrome Steel Balls are normally used in precision ball bearings and many industrial applications.For example: high speed low noise

bearings, bicycles, motorcycles, automobiles, slide rail, universal ball, bags, electronics industry. They can also be used to grind other mediums.

bearings, bicycles, motorcycles, automobiles, slide rail, universal ball, bags, electronics industry. They can also be used to grind other mediums.

Characteristic:

Bearing steel balls easily become the most common ball material, producing tens of millions of them every year. They are almost perfectly round and mirror polished to provide precise rotational motion in machines, power tools, motors, power transmissions and hundreds of other applications.

Compare:

Chrome steel

is also called high-carbon chromium steel. The carbon content Wc is about 1%, and the chromium content Wcr is about 1.5%. From its birth in 1901 to the present 100 years, the main components have basically not changed, accounting for 80% of the world's total bearing steel production. %the above.

Chemical composition:

If there is no special description for bearing steel, it refers to GCr15.

Chemical composition: C: 0.95-1.05; Mn: 0.20-0.40; Si: 0.15-0.35; S: ≤0.020; P: ≤0.027; Cr: 1.30-1.65; Mo: ≤0.10; Ni: ≤0.30; Cu: ≤ 0.25; Ni+Cu≤0.50.

Specification

Detailed production process of steel balls

1. Wire drawing (wire drawing):

Stretch the wire to the required wire diameter with a wire drawing machine;

2. Heading :

Put the drawn wire into the steel ball cold heading machine, and upset it into a ball embryo by the steel mold in the machine;

3. Flashing:

The two cast iron grinding ball discs in the light ball machine rasps the cold heading ball embryo under pressure to remove the outer ring and two poles on the ball embryo;

4. Soft grinding:

The two cast iron grinding ball discs in the soft ball machine rasps the photosphere ball embryo to grind the ball embryo to the required ball diameter and surface roughness;

5. Heat treatment:

Put the ball into the heat treatment furnace to be carburized and then quenched and then tempered to make the ball have a certain carburized layer, hardness, toughness and crushing load;

6. Hard grinding:

The grinding wheel disc in the grinder presses and grinds the heat-treated ball embryo to remove the black oxide layer on the surface of the ball and correct the accuracy of the ball;

7. Lapping/polishing cleaning:

Hot Searches