- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Eps Foam Mould

-

Certification:

-

CE

-

Application area:

-

Foam box, insulation concrete foam, packaging

-

Mould life:

-

10 years

-

Mould Frame Material:

-

Aluminum Alloy 6063

-

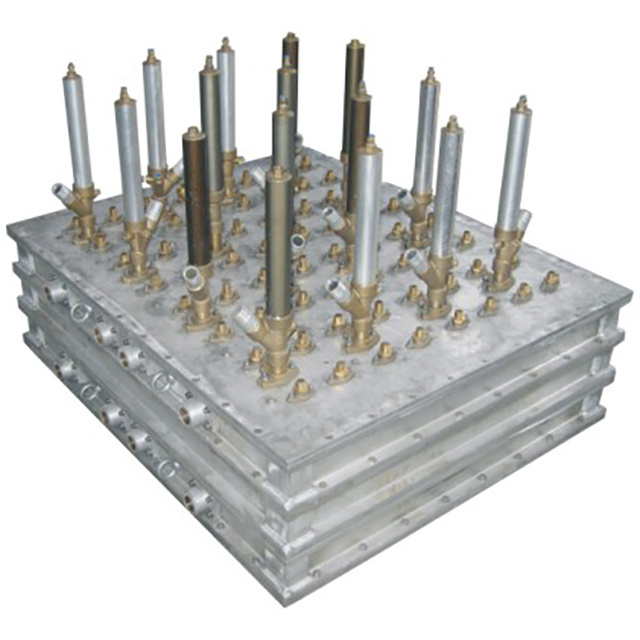

Component:

-

Model frame(steam chamber) , mold core, copper pipes

-

Design software:

-

CAD

-

After-sales Service Provided:

-

Online support

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Joseph

-

Product Name:

-

Eps Foam Mould

-

Certification:

-

CE

-

Application area:

-

Foam box, insulation concrete foam, packaging

-

Mould life:

-

10 years

-

Mould Frame Material:

-

Aluminum Alloy 6063

-

Component:

-

Model frame(steam chamber) , mold core, copper pipes

-

Design software:

-

CAD

-

After-sales Service Provided:

-

Online support

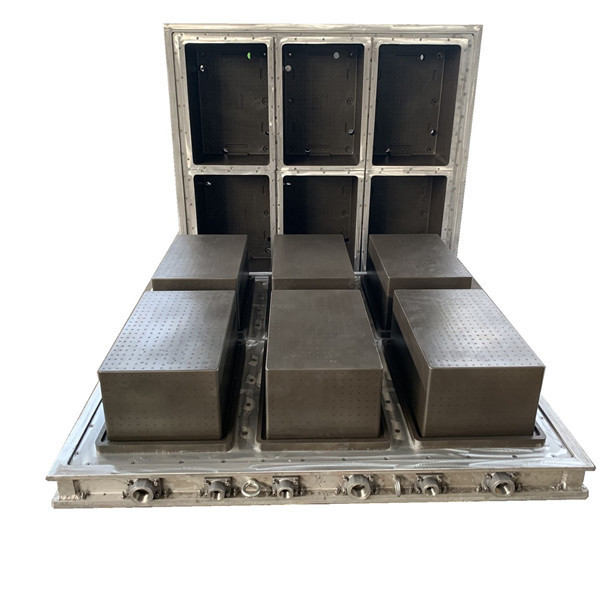

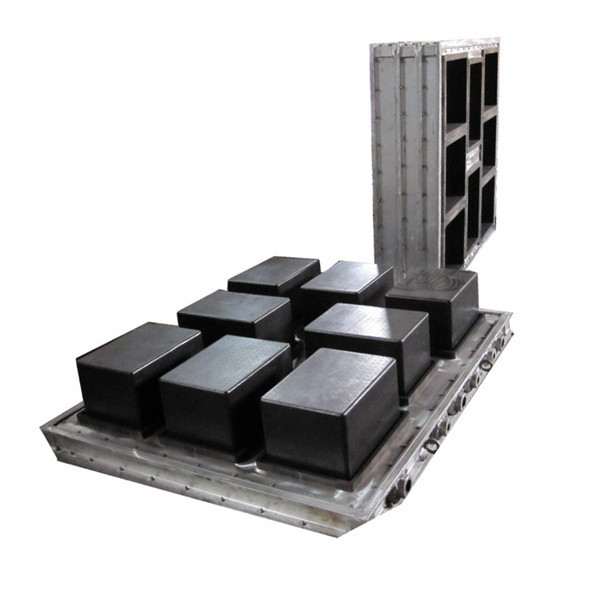

Products Description

We adopt CAD and other design softwares to design and manufacture EPS, EPP plastic moulds. All moulds are made by high-quality aluminum alloy with Telfon coating, assembled by standard frames and cooling system, which achieves conventientde-moulding, anti-corrosion, high temperature resistence and long life. Our is capable of manufacturing highly customized moulds in accordance with clients' varieties of machines.

|

Material

|

High quality 6063 aluminum alloy

|

|

Application

|

EPS Packaging Box. Styrofoam Icf Blocks, Decoration Cornice and other EPS Productions

|

|

Package

|

Wooden Case Packaging

|

|

Shape

|

Customized

|

|

Service

|

Convert customer's samples to CAD drawing , test mould before delivery

|

1.Pictures of

Eps Foam Mould

2.The mould production process is as follow

1. EPS mold is made of high quality aluminum material, and mould frame is made by extruded aluminum alloy profile, strong and long lasting.

2. EPS mold are processed by CNC machines, mould sizes are precise.

3. We have strict quality control in all steps: patterning, casting, machining, assembling, Teflon coating etc.

3. We have strict quality control in all steps: patterning, casting, machining, assembling, Teflon coating etc.

4. We can deliver the aluminum molds quickly, test EPS molds and check samples carefully before delivery;

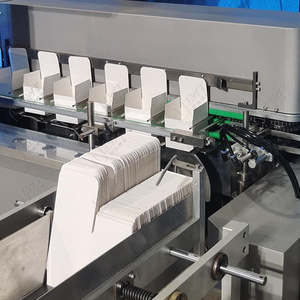

5. Our engineer have rich experience to make designs. We can design any difficult moulds for clients. Such like EPS fruit box mould, EPS cornice mould, EPS fish box mould, EPS ICF block mould, EPS seeding tray mould, all kinds of EPS electrical packaging products mould etc.

6. We can convert customer’s samples to CAD drawing or 3D drawings.

6. We can convert customer’s samples to CAD drawing or 3D drawings.

3.Application of

Eps Foam Mould

Hot Searches