- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ralead

-

Model Number:

-

R930

-

Type:

-

silane polymer sealant

-

Appearance:

-

Gray paste

-

Extrudability(ml/min):

-

200

-

Surface drying time (min):

-

40

-

Elongation at break (%):

-

900

-

Tensile strength (Mpa):

-

≥1.0

-

Elastic recovery rate (%):

-

≥80

-

Tensile modulus (MPa):

-

≤0.4

-

Fixed-stretch cohesiveness:

-

No damage

-

High modulus:

-

Adhesives & Sealants

-

Anti-fall:

-

MS Sealant

Quick Details

-

CAS No.:

-

112926-00-8

-

Other Names:

-

Silica

-

MF:

-

O2Si

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ralead

-

Model Number:

-

R930

-

Type:

-

silane polymer sealant

-

Appearance:

-

Gray paste

-

Extrudability(ml/min):

-

200

-

Surface drying time (min):

-

40

-

Elongation at break (%):

-

900

-

Tensile strength (Mpa):

-

≥1.0

-

Elastic recovery rate (%):

-

≥80

-

Tensile modulus (MPa):

-

≤0.4

-

Fixed-stretch cohesiveness:

-

No damage

-

High modulus:

-

Adhesives & Sealants

-

Anti-fall:

-

MS Sealant

Product Description

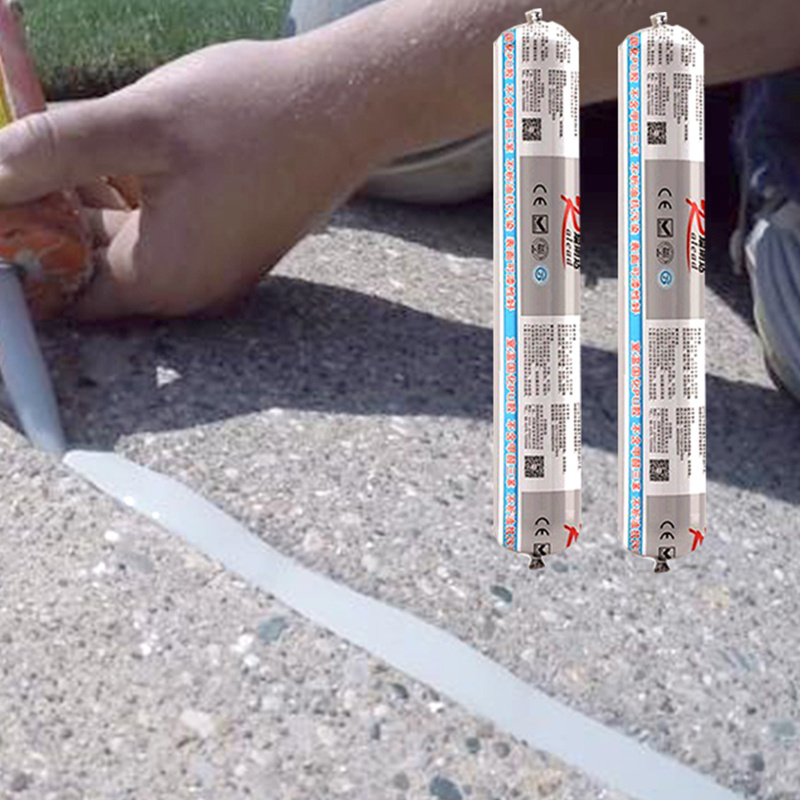

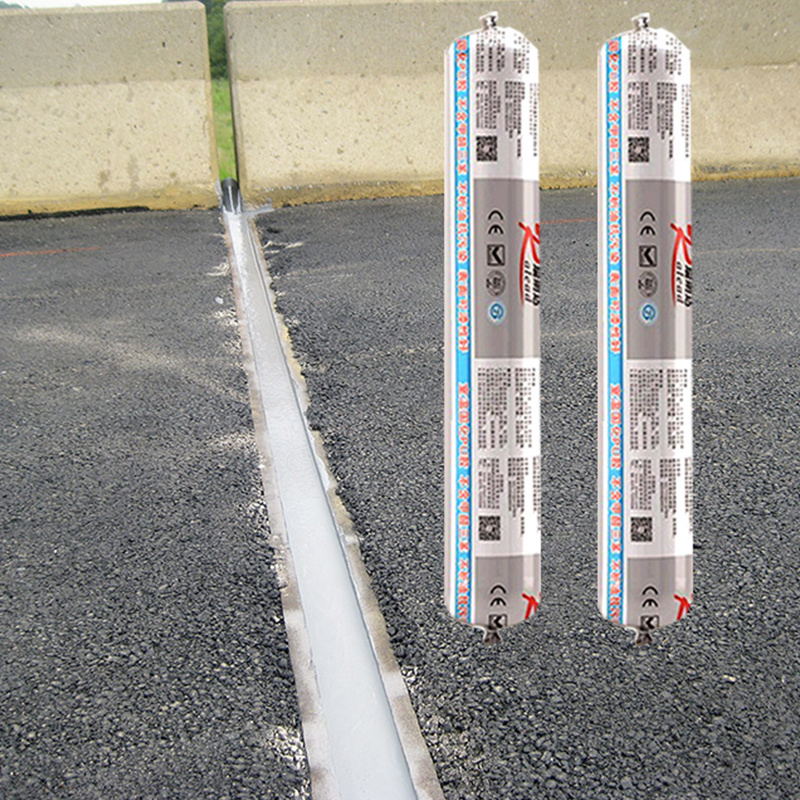

R930 is a non-sagging type, and R930L is a

self-leveling

type. They are both single-component neutral curing sealants. The

modified silane polymer sealant

is specially designed for long-term weather-resistant sealing of expansion joints, shrinkage joints, and longitudinal joints of airport runways, highways, tunnels, bridges and other concrete or asphalt pavements. It has low modulus and high displacement characteristics and is suitable for Displacement of concrete joints.

Application

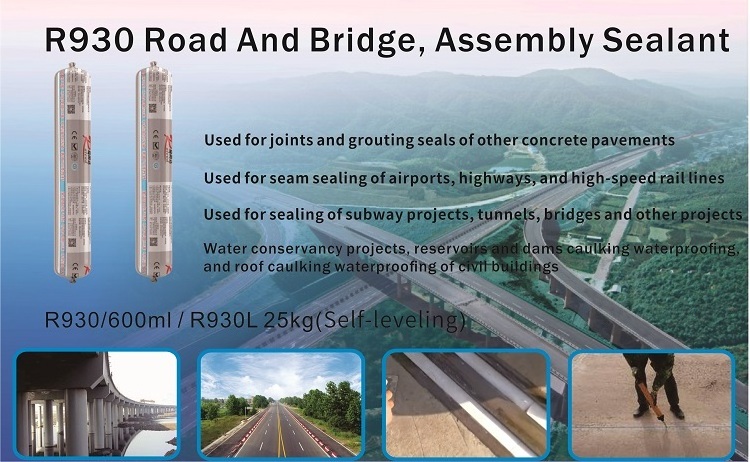

1. Used for seam sealing of airports, highways, and high-speed rail lines.

2. Used to seal the joints and grouting joints of other concrete pavements.

3. Used for sealing of subway projects, tunnels, bridges and other projects.

4. Used for caulking and waterproofing of water conservancy projects and reservoir dams.

5. Used for roof caulking waterproofing of industrial and civil buildings.

Technical Parameters

|

Main chemical composition

|

|

Modified Silane

|

|

||

|

Model

|

|

R930

|

R930L

|

||

|

Appearance

|

|

Gray paste

|

Gray self-leveling

|

||

|

Sag(mm)

|

|

0

|

/

|

||

|

Extrudability(ml/min)

|

|

200

|

400

|

||

|

Surface drying time (min)

|

|

40

|

45

|

||

|

Elongation at break (%)

|

|

900

|

1000

|

||

|

Tensile strength (Mpa)

|

|

≥1.0

|

|

||

|

Elastic recovery rate (%)

|

|

≥80

|

|

||

|

Tensile modulus (MPa)

|

|

≤0.4

|

|

||

|

Fixed-stretch cohesiveness

|

|

No damage

|

|

||

|

Adhesion after cold drawing-hot pressing, water immersion and heat treatment

|

|

No damage

|

|

||

|

Thermal aging

|

Thermal weight loss (%)

|

3

|

|

||

|

|

Cracking, chalking

|

None

|

|

||

Packaging specification

R930 uses aluminum film: 600ml/pcs, 20pcs/carton

R930L uses plastic barrel: 25kg/barrel

R930L uses plastic barrel: 25kg/barrel

Quality inspection

Obtained a number of patent certificates

Latest IOS 9001-2020; UV: CE and other international safety certification

Hot Searches