1. The casting structure is stable, reasonable and beautiful. The cast iron of our company is cast with HD250 grade, which has time aging and annealing aging to ensure that the cast iron body is stable and not deformed and durable.

2. The main parts of the fuselage are the first and second configuration parts imported from the same industry: for example: the guide rails are precision grade guide rails from Taiwan Shangyin or Yintai or ABBA; the screw rods are Japan's NSK, THK or German Rexroth (Rexroth); the system adopts Taiwan's new generation bus absolute value control system and integrated drive; the servo motor adopts the high inertia of Japan's Panasonic servo motor; the wire adopts Japanese wire and custom wire;

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

400mm

-

Dimension(L*W*H):

-

1450*1600*2100mm

-

Weight (T):

-

1.5 T

-

Table Travel (Z) (mm):

-

350mm

-

Range of Spindle Speed(r.p.m):

-

1000 - 36000 r.p.m

-

Spindle Motor Power(kW):

-

6KW

-

Max. Table Load(kg):

-

1500 kg

-

Feed Speed(mm/min):

-

100 - 12000 mm/min

-

Rapid Feed Speed(m/min):

-

12

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

RUIYI

-

Voltage:

-

380V/220V

-

System configuration:

-

TaiWan SynTech/Japan MITSUBISH

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Material:

-

Aluminum Steel Iron Copper

-

Keyword:

-

CNC Carving Machine

-

Applicable industry:

-

Mould Industry

-

Machine Type:

-

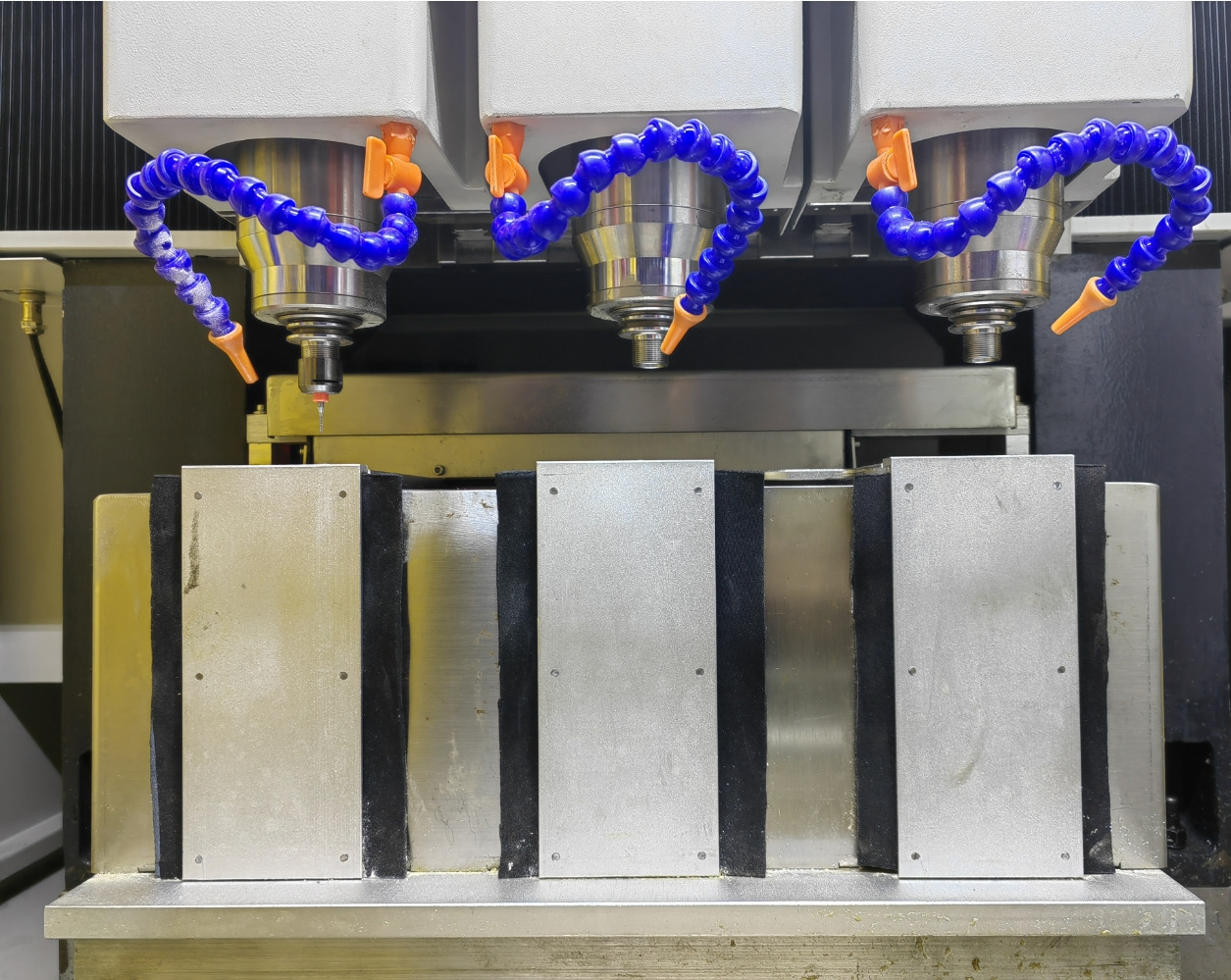

CNC Vertical Machining Center

-

Application:

-

Metal Working Mould Processing

-

Control system:

-

SIEMENS LNC SYNTEC FANUC MITSUBISHI(optional)

Quick Details

-

Table Size (mm):

-

500*400mm

-

Number of Axes:

-

3, 4, 5, 6

-

Table Travel (X) (mm):

-

500mm

-

Table Travel (Y) (mm):

-

400mm

-

Dimension(L*W*H):

-

1450*1600*2100mm

-

Weight (T):

-

1.5 T

-

Table Travel (Z) (mm):

-

350mm

-

Range of Spindle Speed(r.p.m):

-

1000 - 36000 r.p.m

-

Spindle Motor Power(kW):

-

6KW

-

Max. Table Load(kg):

-

1500 kg

-

Feed Speed(mm/min):

-

100 - 12000 mm/min

-

Rapid Feed Speed(m/min):

-

12

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

RUIYI

-

Voltage:

-

380V/220V

-

System configuration:

-

TaiWan SynTech/Japan MITSUBISH

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Material:

-

Aluminum Steel Iron Copper

-

Keyword:

-

CNC Carving Machine

-

Applicable industry:

-

Mould Industry

-

Machine Type:

-

CNC Vertical Machining Center

-

Application:

-

Metal Working Mould Processing

-

Control system:

-

SIEMENS LNC SYNTEC FANUC MITSUBISHI(optional)

Products Description

Applicable industries: ceramics, glasses, fiberboard, mobile phones, molds, hardware (hardware accessories in various industries), glass, auto parts, electronic cigarettes, smart wear, PCD circuit boards, accessories, handicrafts, die-casting parts, jewelry, seal signs,

|

A

|

Technical parameters of machine tool:

|

|

|

|

|

||||

|

1

|

The machine body and all parts are made of nano castings

|

|

|

|

|

||||

|

2

|

Table size

|

|

|

500×400mm

|

|

||||

|

3

|

T-groove (width x quantity x spacing)

|

|

|

10×5×78mm

|

|

||||

|

4

|

The largest load

|

|

|

200KG

|

|

||||

|

5

|

Maximum feed height

|

|

|

280mm

|

|

||||

|

6

|

Distance from spindle face to work

|

|

|

100-280mm

|

|

||||

|

7

|

Triaxial travel X/Y/Z

|

|

|

450/400/170mm

|

|

||||

|

8

|

The spindle diameter

|

|

|

Ǿ100mm

|

|

||||

|

9

|

Spindle speed

|

|

|

36000RPM

|

|

||||

|

10

|

Spindle motor power

|

|

|

6KW

|

|

||||

|

11

|

Spindle tool library capacity

|

|

|

8

|

|

||||

|

12

|

Tool change time

|

|

|

5S

|

|

||||

|

13

|

The spindle taper

|

|

|

ISO25

|

|

||||

|

14

|

Knife library classes

|

|

|

Servo disc rotation

|

|

||||

|

15

|

Fast moving rate X/Y/Z

|

|

|

12/12/12m/Min

|

|

||||

|

16

|

Processing speed

|

|

|

6-12m/Min

|

|

||||

|

17

|

Positioning accuracy

|

|

|

±0.006/300mm

|

|

||||

|

18

|

Repetitive positioning accuracy

|

|

|

±0.006/300mm

|

|

||||

|

19

|

Machined surface accuracy

|

|

|

≤Ra1.6

|

|

||||

|

20

|

The machining accuracy

|

|

|

±0.01mm

|

|

||||

|

21

|

Optional four-axis five-axis

|

|

|

Yes

|

|

||||

|

22

|

Angle of rotation of axis A

|

|

|

±105 degrees

|

|

||||

|

23

|

Fifth axis C axis rotation Angle

|

|

|

360 degrees

|

|

||||

|

24

|

Five-axis linkage mode

|

|

|

5 axis with the move

|

|

||||

|

25

|

Working voltage

|

|

|

380V/50HZ±10% or 220V/60HZ

|

|

||||

|

26

|

Machine size (l * W * H)

|

|

|

1450×1600×2100mm

|

|

||||

|

27

|

The body weight

|

|

|

1500KG

|

|

||||

|

B

|

Machine tool configuration details brand parameters:

|

|

|

|

|

||||

|

1

|

The system configuration

|

|

|

Taiwan SYNTEC 6GA/Ncstudio280/LNC

|

|

||||

|

2

|

The spindle

|

|

|

6KW high-precision, high-speed, high-quiet oil-cooled spindle

|

|

||||

|

3

|

Ball screw

|

|

|

Japan NSK, Germany RexRoth) 2005

|

|

||||

|

4

|

Linear guide

|

|

|

Taiwan HIWIN/ABBA high precision guide H25

|

|

||||

|

5

|

Servo unit

|

|

|

Panasonic Servo motor 750W/Ncstudio

|

|

||||

|

6

|

Wire rod bearing

|

|

|

Taiwan TPI precision grade bearing

|

|

||||

|

7

|

Switching power supply

|

|

|

Taiwan Ming weft

|

|

||||

|

8

|

Electric switch

|

|

|

China chint

|

|

||||

|

9

|

converter

|

|

|

* Square converter

|

|

||||

Hot Searches