China rubber crusher equipment crumb rubber grinding tire shredder waste tyre recycling machine prices is main used for waste rubber tyre.The machines feature optimized high capacity ,low noise , engery save.This Crusher has various models with wide application range to meet different customer's demand.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XKP350

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

2000x1800x1750

-

Year:

-

2023

-

Weight (KG):

-

5000 kg

-

Power (kW):

-

83.95

-

Product name:

-

Waste Tire Recycling Production Line Tyre Shredder

-

Application:

-

Tyre shredders for sale in south africa

-

Raw material:

-

Waste Car tire, OTR tire

-

Usage:

-

Rubber recycling machine

-

Related machine:

-

Rubber tile machine

-

Keyword:

-

Recycling

-

Machine Type:

-

Fully automatic

-

Advantage:

-

Whole production line

-

Final product:

-

Rubber crumb,rubber powder

-

Certification:

-

CE Certification

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huarui tire recycle

-

Marketing Type:

-

High Productivity

-

Model Number:

-

XKP350

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

2000x1800x1750

-

Year:

-

2023

-

Weight (KG):

-

5000 kg

-

Power (kW):

-

83.95

-

Product name:

-

Waste Tire Recycling Production Line Tyre Shredder

-

Application:

-

Tyre shredders for sale in south africa

-

Raw material:

-

Waste Car tire, OTR tire

-

Usage:

-

Rubber recycling machine

-

Related machine:

-

Rubber tile machine

-

Keyword:

-

Recycling

-

Machine Type:

-

Fully automatic

-

Advantage:

-

Whole production line

-

Final product:

-

Rubber crumb,rubber powder

-

Certification:

-

CE Certification

Product Description

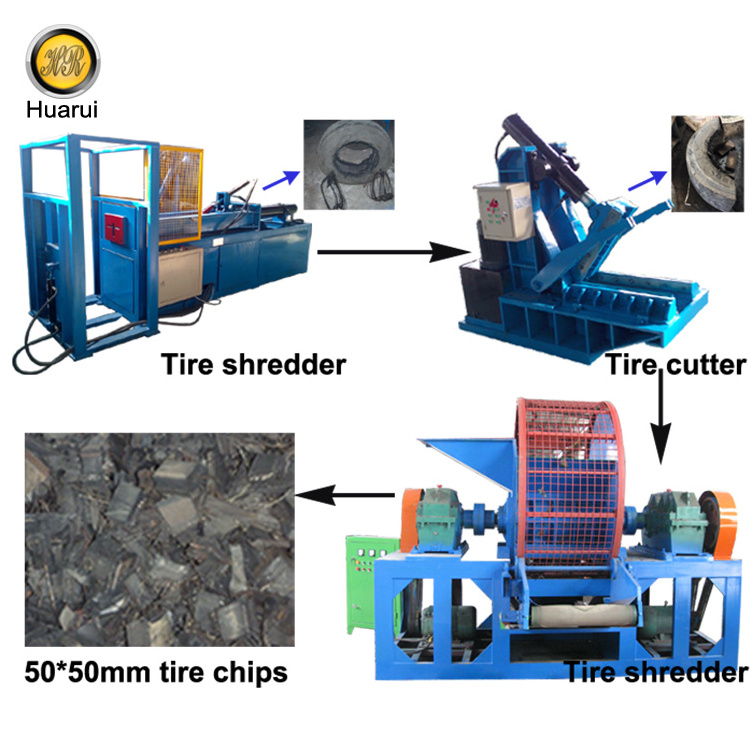

Automatic Waste Tyre Recycle production Line

Step 1: Draw steel wire from the tire ring by Tire wire drawing machine.

Step 2: If the diameter of tire is bigger than 900 mm , can choose to use tire cutting machine to cut the

tire to several pieces.Full Automatic High Efficiency Waste Tyre Recycling Machine for Rubber Powder

Step 3 : Put the small tires or pieces into tire shredder to make tire blocks.

Step 4: Put the tire blocks to the tire crusher to make rubber powder.

You can choose the model according to

rubber size and capacity

you need ,more models as below

|

Model NO.

|

Hour Capacity(kg/h)

|

|

Day Capacity

|

|

|

Auto-400 Line

|

10 mesh(2.5mm)

|

400-500kg/h

|

6-12Ton/day

|

|

|

|

20 mesh(1.25mm)

|

300-350kg/h

|

|

|

|

|

30 mesh(0.83mm)

|

240-280kg/h

|

|

|

|

|

40 mesh(0.63mm)

|

150-175kg/h

|

|

|

|

Auto-450 Line

|

10 mesh(2.5mm)

|

500-600 kg/h

|

8-16Ton/day

|

|

|

|

20 mesh(1.25mm)

|

400-500 kg/h

|

|

|

|

|

30 mesh(0.83mm)

|

350-450 kg/h

|

|

|

|

|

40 mesh(0.63mm)

|

200-250 kg/h

|

|

|

|

Auto-560 Line

|

10 mesh(2.5mm)

|

900-1000 kg/h

|

10-20Ton/day

|

|

|

|

20 mesh(1.25mm)

|

600-700 kg/h

|

|

|

|

|

30 mesh(0.83mm)

|

450-550 kg/h

|

|

|

|

|

40 mesh(0.63mm)

|

300-350 kg/h

|

|

|

|

Auto-560L Line |

10 mesh(2.5mm)

|

1500-1600 kg/h

|

12-24Ton/day

|

|

|

|

20 mesh(1.25mm)

|

1200-1300 kg/h

|

|

|

|

|

30 mesh(0.83mm)

|

1000-1100kg/h

|

|

|

|

|

40 mesh(0.63mm)

|

800-900 kg/h

|

|

|

Specification of machine

|

Model No.

|

XKP-350

|

XKP-400

|

XKP-450

|

XKP-560

|

XKP-560D

|

|

Diameter of front roll

|

300 mm (groove)

|

400 mm (groove)

|

450 mm (groove)

|

560 mm (groove)

|

560 mm (groove)

|

|

Diameter of back roll

|

300 mm (groove)

|

400 mm (groove)

|

450 mm (groove)

|

510 mm (groove)

|

560 mm (groove)

|

|

Drum working length

|

500mm

|

600mm

|

760mm

|

800mm

|

1000mm

|

|

Front roll liner speed

|

26.2m/min

|

34.5 m/min

|

38.0 m/min

|

40.6m/min

|

44m/min

|

|

Roll ratio

|

01:02.5

|

01:02.5

|

01:02.5

|

01:02.5

|

01:02.5

|

|

Max roller spacing

|

10mm

|

10 mm

|

10 mm

|

10 mm

|

10mm

|

|

Motor power

|

30KW/37KW

|

45KW/55KW

|

75KW /90KW

|

90KW/110KW

|

132KW/160KW

|

|

Weight

|

6T

|

8.5 T

|

11T

|

17.5T

|

21T

|

|

L*W*H

|

3.5*1.6*1.5m

|

4.3*1.8*1.6m

|

4.6*2.0*1.65m

|

5.3*2.0*1.7m

|

5.6*2.0*1.7m

|

Detailed photos

Successful project

Company Introduction

Xuchang Huarui Machinery Co., Ltd. is specialized in producing the tire recycling plant for nearly 30 years and we provide 2 years warranty for our machines

We provide the most suitable proposal according to client's demand , any needs , please contact

:

Bella , Whatsapp/Wechat 0086 13937476212

FAQ

--1--Q: How to choose a suitable tire recycling line?

A: Please tell us the end product you want to produce, rubber block or rubber powder, and the HOUR CAPACITY & OUTPUT SIZE, we will recommend you the most suitable tire recycling line.

--2--Q: What size of rubber powder can i get from the recycling line?

A: 5-40mesh rubber powder.

--3--Q: Can we get very fine powder from the recycling line?

A: Yes, you can get 40-100mesh fine rubber powder with fine grinder system.

--4--Q: Can you process OTR tires?

A: Yes, we have machines special for OTR tires.

--5--Q: What about the machine installation?

A: We will send engineers to customer working site for the installation guidance, commissioning and training when everything is ready on the working site, like power, cable, labors, forklift, etc.

--6--Q: How about the spare parts?

A: We will send one set spare parts for free with machine. And if more, spare parts will be sold at cost price permanently and will give you the spare parts list when you purchase machine.

--7--Q: Will you test the machine before delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

--8--Q: How about the delivery time and packing details?

A: 20days after receiving the deposit. Package in the whole container.

Hot Searches