- Product Details

- {{item.text}}

Quick Details

-

Input Voltage:

-

380V 50Hz/60Hz

-

Use:

-

PVEF MPP PP PE PB PPR Material Pipe Butt Welding

-

Power (kW):

-

2.3Kw

-

Weight (KG):

-

800 KG

-

Product name:

-

Pipe butt welding machine

-

Pipe Sizes:

-

90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315MM

-

Heating board max temp.:

-

270 °C

-

Temperature bias:

-

±5°c

-

Pressure adjustable range:

-

0-10Mpa

-

Working Voltage:

-

380V,50Hz/60Hz

-

Heating Plate Power:

-

5.15KW/380V

-

Hydraulic unit power:

-

1.5 KW/380v

-

Application:

-

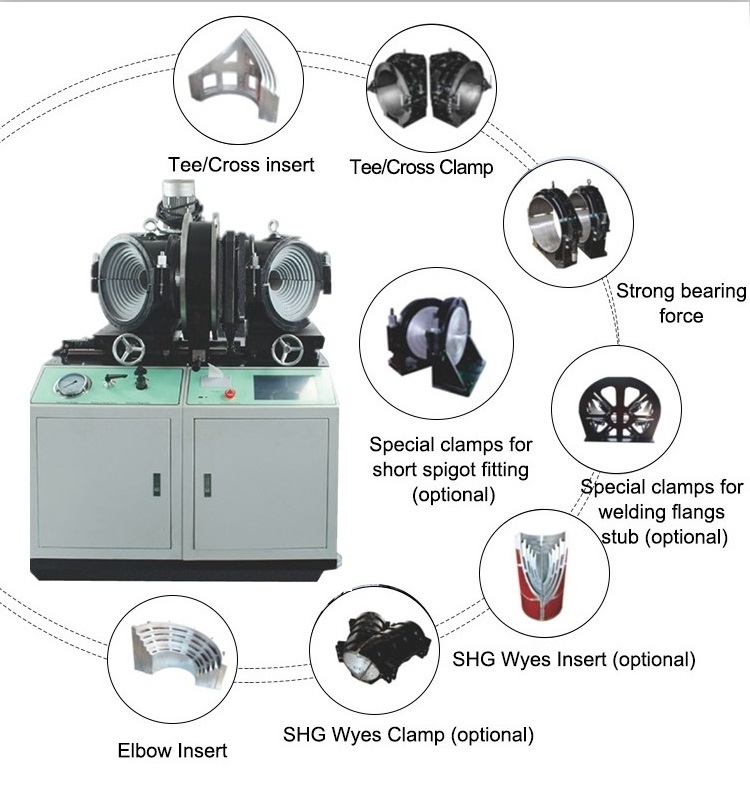

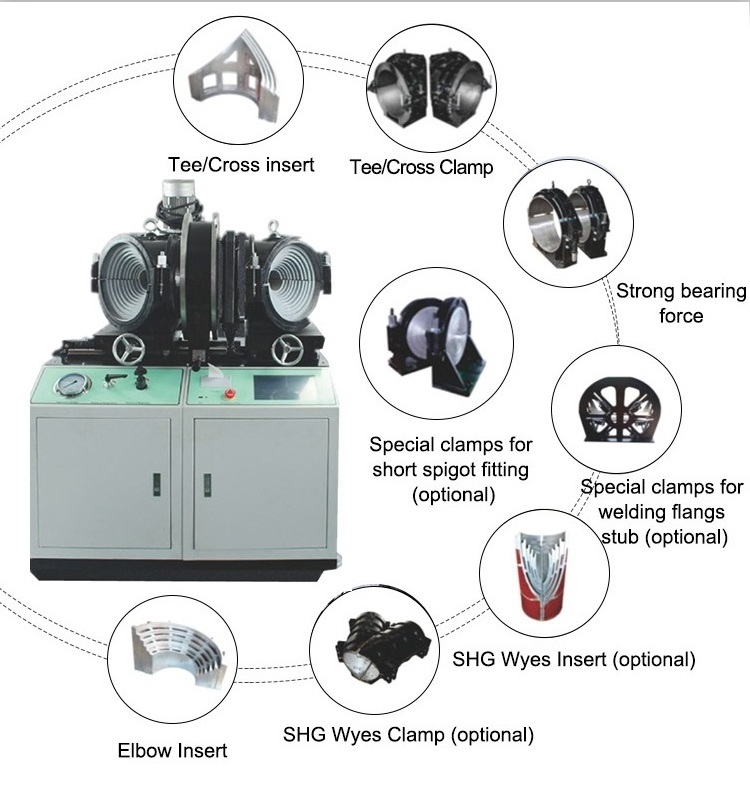

0~90°elbow, tee, cross, 45° and 60°Y (optional parts should be used)

-

Total Weight:

-

800KG

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Suntech

-

Input Voltage:

-

380V 50Hz/60Hz

-

Use:

-

PVEF MPP PP PE PB PPR Material Pipe Butt Welding

-

Power (kW):

-

2.3Kw

-

Weight (KG):

-

800 KG

-

Product name:

-

Pipe butt welding machine

-

Pipe Sizes:

-

90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315MM

-

Heating board max temp.:

-

270 °C

-

Temperature bias:

-

±5°c

-

Pressure adjustable range:

-

0-10Mpa

-

Working Voltage:

-

380V,50Hz/60Hz

-

Heating Plate Power:

-

5.15KW/380V

-

Hydraulic unit power:

-

1.5 KW/380v

-

Application:

-

0~90°elbow, tee, cross, 45° and 60°Y (optional parts should be used)

-

Total Weight:

-

800KG

Products Information

|

Product Name

|

90-315m Multi Angle Workshop Fitting Butt Welders Welding Fitting Machine Hdpe Fabrication PP PE PPR Butt Fusion Welding Machine

|

|

Model

|

HDG315

|

|

Pipe Sizes

|

90mm, 110mm, 125mm, 140mm, 160mm, 180mm, 200mm, 225mm, 250mm, 280mm, 315mm

|

|

Application

|

0~90°elbow, tee, cross, 45° and 60°Y (optional parts should be used)

|

|

Heating Plate Max. Temp.

|

270°c

|

|

Temp. deviation in surface

|

±5°c

|

|

Pressure adjustable range

|

0-10Mpa

|

|

Working Voltage

|

380V,50Hz/60Hz

|

|

Heating Plate Power

|

5.15KW/380V

|

|

Hydraulic unit power

|

1.5 KW/380v

|

|

Planing tool/Milling cutter power

|

1.5 KW/380v

|

|

Total Power

|

8.15 KW/380v

|

|

Total Weight

|

800KG

|

Features

1. Workshop fitting welding machine SHBG 315/110 with printing is suitable for fabricating elbow, tee, cross and we shape (45 and

609) Fittings of PE, PP, PVDF in work shop

2. Base on the integrated design, if welded different fitting you just need to replace the corresponding fixture

3. Heating plate uses independent temperature control system, removable PTFE coated

4. Electric face with safety limit switch can avoid the milling cutter accidental starting.

5. Low starting pressure ensures reliable welding quality of small pipes.

6.Separate two-channel timer can show both of soaking and cooling time

7. High-precision and shockproof pressure meter displays records clearly

8. Heating plate, milling cutter and support plate is on the linear guide track

9. Complies with 98/37 and 73/23 EEC standards

10. Optional components: short flange welding fixture, short pipe welding fixture.

609) Fittings of PE, PP, PVDF in work shop

2. Base on the integrated design, if welded different fitting you just need to replace the corresponding fixture

3. Heating plate uses independent temperature control system, removable PTFE coated

4. Electric face with safety limit switch can avoid the milling cutter accidental starting.

5. Low starting pressure ensures reliable welding quality of small pipes.

6.Separate two-channel timer can show both of soaking and cooling time

7. High-precision and shockproof pressure meter displays records clearly

8. Heating plate, milling cutter and support plate is on the linear guide track

9. Complies with 98/37 and 73/23 EEC standards

10. Optional components: short flange welding fixture, short pipe welding fixture.

Welding Introduction For HDPE:

Welding Introduction For HDPE:

1. Fix the proper clamps on the machine rack.

2. Put HDPE pipes on the clamps and tighten the bolts.

3. Mill the end of the HDPE pipes with the facer.

4. Put the heater plate on the machine rack and heat the pipes for proper time.

5. Remove the heater plate and connect the HDPE pipes.

Hot Products

Products Categories

Hot Searches