- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Classfication:

-

dental lab heating processing equipment

-

Application:

-

lab muffle furnace for zirconia sintering

-

style:

-

1700.C electric muffle furnace for ceramic

-

type:

-

high temperature sintering ceramic furnace

-

Max. temperature:

-

1700.C

-

working temperature:

-

1600.C continuous

-

Chamber size:

-

300*200*200mm

-

use:

-

electric furnace for ceramic sintering

-

usage:

-

1700C sintering furnace for porcelain

-

Voltage:

-

220V

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

Xinkyo

-

Model Number:

-

SX2-9-17TP

-

Place of Origin:

-

Henan, China

-

Classfication:

-

dental lab heating processing equipment

-

Application:

-

lab muffle furnace for zirconia sintering

-

style:

-

1700.C electric muffle furnace for ceramic

-

type:

-

high temperature sintering ceramic furnace

-

Max. temperature:

-

1700.C

-

working temperature:

-

1600.C continuous

-

Chamber size:

-

300*200*200mm

-

use:

-

electric furnace for ceramic sintering

-

usage:

-

1700C sintering furnace for porcelain

-

Voltage:

-

220V

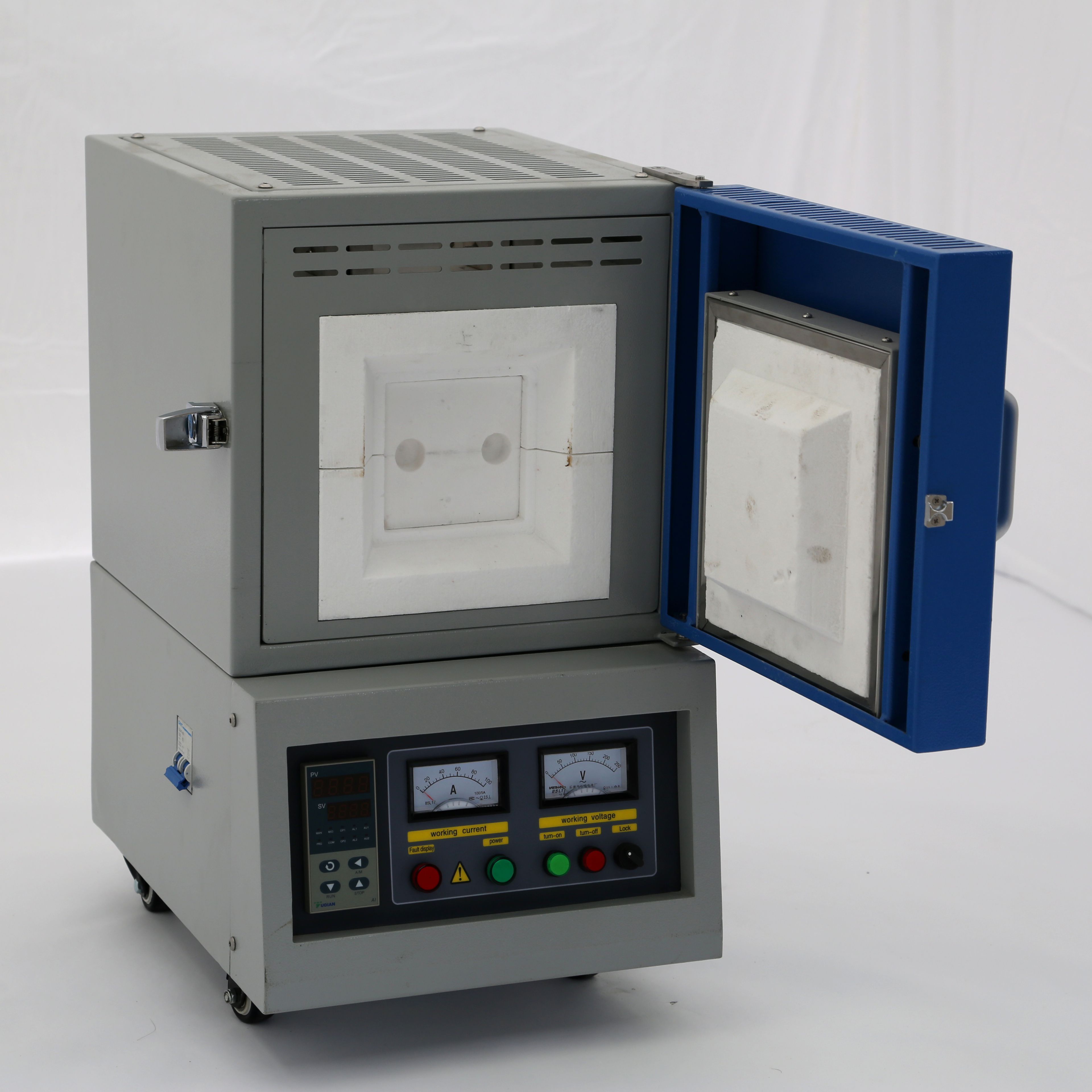

High Quality Wholesale Price Programmable 1700 deg C Gemstone Heat Treatment Gem Heating Machine Gem Heating Furnace

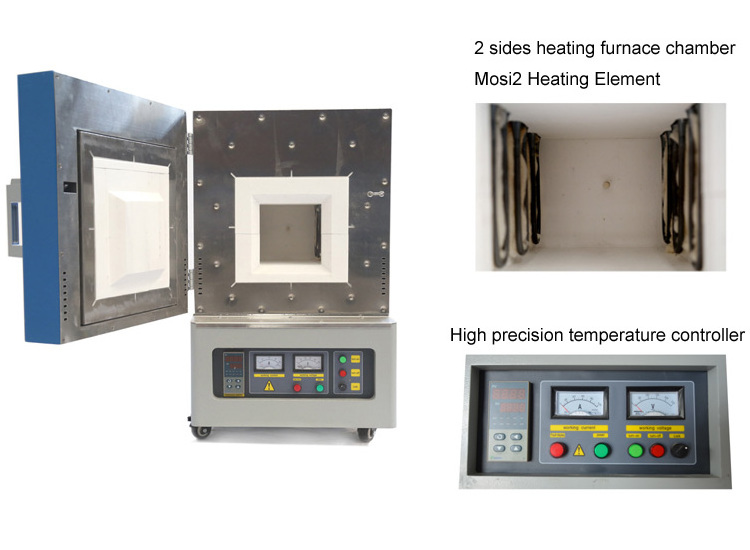

XY series box furnaces are the most cost effective bench-top high temperature muffle furnace. The furnace consists of high quality alumina fiber brick and MoSi2 heating elements with special design, and furnace temperature is controlled byhigh precision SCR (Silicon Controlled Rectifier) digital controller with accuracy ±1℃ and 30 segments programmable. It is an ideal tool for Materials annealing and sintering in your research laboratory.

Product a pplication : Widely used in enterprises and institutions scientific research and small batch production, as well as colleges and universities involved in scientific research and teaching of ceramics, metallurgy, electronics, glass, chemical, machinery, refractory materials, new material development, special materials, building materials in the field.

The detail specifications of high temperature lab electric furnace

| Max.temperature | 1700C |

| Working temperature | 0-1600C |

| Furnace Chamber size(DWH)mm | 300*200*200 or as your requirement |

| Heat element | MoSi2 heater |

| voltage and frequency | 220v 50Hz/60Hz |

| Heating rate | 0-20C/min |

| Temperature accuracy | ±1°C |

| Thermocouple | B type |

|

Temperature control |

Adopt international advanced temperature controller, with 30-50 programmable PID self-tuning, automatic temperature rise, automatic temperature drop, no duty. |

|

Appearance design |

The electric furnace adopts humanized design, beautiful and easy to operate, and the outer layer of paint is sprayed with high temperature baking technology. High temperature resistance, oxidation resistance, acid and alkali resistance. Color selection is aging resistant tone, will not cause the appearance color fade due to a long time of use. |

|

Furnace shell structure |

Electric furnace shell adopts double layer forced air cooling structure, so that the electric furnace works at the highest temperature and the external temperature of the shell is close to room temperature, so as to avoid accidental injury. |

|

Temperature control security |

The electric furnace adopts integrated circuit, module control, double circuit protection (partial temperature protection, ultra-high temperature protection, coupling protection, overcurrent protection, overpressure protection and other protection functions) to make the electric furnace work stable and reliable, safe. |

|

Furnace Chamber material |

Adopt the most advanced light alumina ceramic fiber in the world, with excellent thermal insulation effect, light weight, high temperature resistance, cold and heat resistance, no crack, no crystallization, no slag, do not worry about pollution of the fired products. The energy saving effect is 60-80% of the old electric furnace. |

|

Furnace chamber design |

Furnace adopts the stepped assembly structure, integrating the mechanical law, effectively ensure the furnace in the heating process of uniform force, ensure that the heat is not easy to disperse, prolong the service life of the furnace. |

| Sandard accessories | Crucible tongs 1pc, Thermal gloves 1 pair,User manual 1 pc,other small tools for assembly furnace |

| Other temperature options | 1200C,1400C,1700C,1800C |

| Furnace chamber standard size | 100*100*100mm,200*150*150mm,300*200*200mm,400*300*300mm or other OEM size |

| Waranty | One year |

Why choose us?

1. Factory Advantages

Xinyu was founded in 2005. We have nearly 17 years of experience in the design and production of high-temperature experimental equipment, with stable quality and a comprehensive daily output of more than 10 sets.

Independent design and research department, constantly innovate and optimize product structure, reduce customer costs and improve product quality.

2. Product materials

The product is made of international standard high-quality ceramic fiber board and ceramic fiber cotton, and the shell is made of SPCC cold-rolled carbon steel plate.

Furnace Shell Structure: Double-layer carbon steel plate shell, surface sprayed with heat resistant plastic powder coating to

ensure that the outer surface temperature of the furnace is ≤40.C.

3. Quality control

Professionals are responsible for each process to check the quality of raw materials and packaging.

Installation test will be carried out before packaging to ensure that each product is intact.

4. After sales service

7 * 24-hour after-sales service to solve all your concerns.

PACKING DETAILS