- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Reliable Machinery

-

Year:

-

2023

-

Voltage:

-

220V-380V customizable

-

Dimension(L*W*H):

-

1950*1850*2100

-

Weight (KG):

-

2000 KG

-

After-sales Service:

-

Provided

-

Blow Moulding Type:

-

Stretch Blow Moulding

Quick Details

-

Neck Diameter(mm):

-

60 mm

-

Max.Bottle Diameter(mm):

-

110 mm

-

Max.Bottle Height(mm):

-

300 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Reliable Machinery

-

Year:

-

2023

-

Voltage:

-

220V-380V customizable

-

Dimension(L*W*H):

-

1950*1850*2100

-

Weight (KG):

-

2000 KG

-

After-sales Service:

-

Provided

-

Blow Moulding Type:

-

Stretch Blow Moulding

RELIABLE BOTTLE BLOWING MACHINE

WE ARE ALWAYS COMMITTED TO SOLVING ALL YOUR DOUBTS AND PROVIDING ONE-STOP PURCHASING SOLUTIONS!

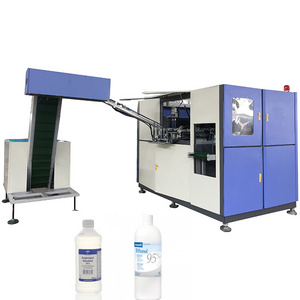

Full Automatic Injection Blow Molding Machine / PET Bottle Blowing For Round Square Bottle

Full automatic bottle blowing machine

Full Automatic Bottle Blow Moulding Equipment is suitable for producing PET plastic containers and bottles in all shapes. The blow moulding machine is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

It can blow the maximum capacity of the products is 2L. It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

APPLICATIONS

Applicable to all kinds of PET bottles which contain oil, soft, drinks, mineral water, wine, medicine, cosmetics, etc.

APPLICATIONS

Applicable to all kinds of PET bottles which contain oil, soft, drinks, mineral water, wine, medicine, cosmetics, etc.

FEATURES

1. Utilization of automatic central lubrication.

2. Compact space design for convenience of mold-conversion, repairing, and maintenance.

3. Minimized transfer pitch for increasing heating efficiency and saving energy.

4. Swift exchange design for preform mandrels.

5. Optimized air flow in the oven for stable heating process.

6.

Easy to adjust, exchange and access heating oven

; Protection for preform thread against heating.

7. Intact rotating robot grip with linear guider for right access, rapid motion; reducing adjustment and maintenance time.

8. Electronic inspector for ejecting faulty preform and bottles.

9.

Fast, safe, and accurate cam-controlled blowing wheel for providing the best bottles.

10. Precise control of blowing technique to produce less-weighted bottle.

11. Smart design for quick conversion of blow mold.

12. Through finite element analysis to optimize modular design for reducing machine wearing and moving inertia.

13. Operating machine through touch panel; program protected by code lock.

(If you are looking for

SEMI AUTOMATIC BOTTLE BLOWING MACHINE

, please click here.)

RELIABLE MACHINERY

15+ years experience in liquid production.

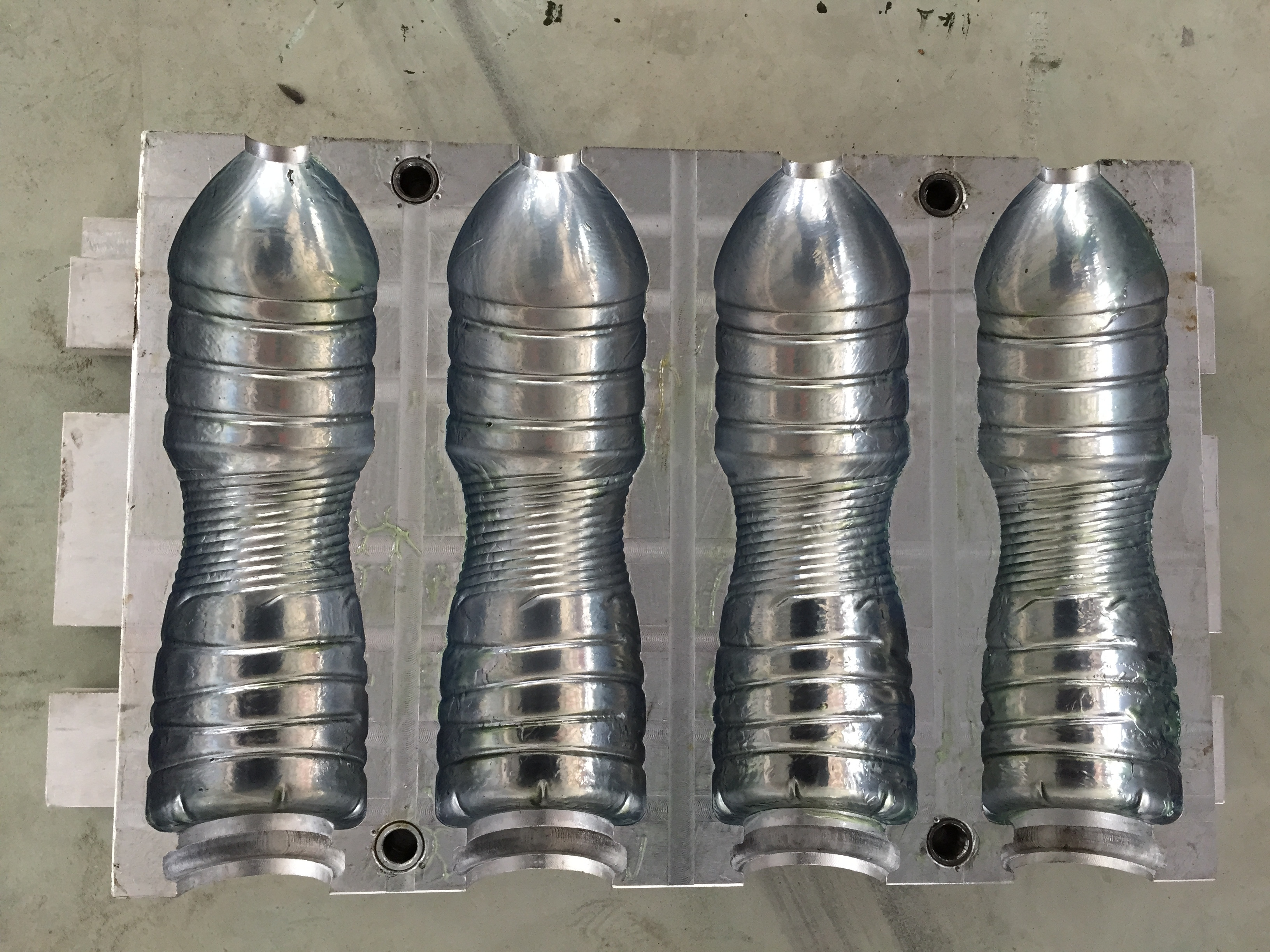

Customized Bottle Design

We provide customized bottle design service

Devoted to bring fine one-stop experience to customers

Special-Designed Factory Installation Layout

Special-Designed Factory Installation Layout

Catering to your unique requirements

Provide the best solution to you

Customized Label Design

Working out a new trend with most attractive label design!

Engineer On-Site Guidence & Training Lessons

Engineer On-Site Guidence & Training Lessons

1. After the machines are delivered to your site, we will send technicians to your factory after preparation work is completed.

2. During the commission, technicians will also give free training lessons to the workers you hire in your factory. Suitable training for the staff using our systems ensures they will be operated and maintained

properly. Advanced technology and multimedia training tools, combined with new concept teaching method.

properly. Advanced technology and multimedia training tools, combined with new concept teaching method.

MORE DETAILS

1).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

2).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

3).High Speed:2000BPH,4000BPH,6000BPH...

4).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

5).Low Cost:Low consumption of electricity, air and water.

6).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

|

Main Part

|

|

|

||

|

Pneumatic part

|

Valve

|

SMC

|

||

|

|

Cylinder

|

SMC

|

||

|

Electric part

|

PLC

|

LG

|

||

|

|

Operating system

|

LG

|

||

|

|

Relay

|

OMRON

|

||

|

|

Infrared thermometer

|

America raytek

|

||

|

Note

|

All of the electrical components adopts CE、UL、CCC approved international advanced high-tech product.

|

|

||

|

Main Parameter

|

|

|

||

|

Model

|

RM-2000/4000/6000...

|

|

||

|

Productivity

|

Depend on bottle design

|

2000/4000/6000/..BPH

|

||

|

Product type

|

Body diameter

|

20mm-100mm

|

||

|

|

Height

|

50mm-350mm

|

||

|

|

Neck diameter

|

15mm-38mm

|

||

|

Mold

|

Cavity

|

2/4/6/...cavities

|

||

|

|

Mold thick

|

240mm

|

||

|

|

Mold

|

500*500mm

|

||

|

Main machine power

|

Electrical source power

|

380v 3Phase /220v 3Phase 50/60HZ

|

||

|

|

Rated Power

|

25kw

|

||

|

|

Really use power

|

6kw

|

||

|

|

Air compressor

|

1.6m3/min 3.0MPa

|

||

|

|

Air dryer

|

2.0m3/min 3.0MPa

|

||

|

Cooling water

|

Cooling water

|

10L/min

|

||

|

Size

|

L*W*H

|

1908*1280*1920mm

|

||

|

|

Weight

|

2000kg

|

||

|

Auxiliary equipment (preform unscrambler)

|

L*W*H

|

2000*950*2480mm

|

||

|

|

Weight

|

250kg

|

||

|

Resin available

|

|

PET

|

||

PRODUCTION DESCRIPTIONS

COMPLETE LINE

WATER FILLING MACHINE PRODUCTION LINE

(Click for more informations)

|

Call us today at

+86 - (512) - 5855 0068

Mob/Whatsapp

+86-185 5118 9313

Email us at

amanda@reliable-machine.com

|

OUR SERVICE

Pre-sale

Swift reply within 24 hours. Well-trained experienced staff multilingual online support.

On-purchase

Exclusive agent actively follow up production and fast delivery.

After-sale

Two-year warranty, Life-time technical support, 24 hours after-sale online service and customized marketing strategy support.

Training Service

Professional engineer training sessions

10-year-experience agent advice on sale techniques

After sale service training

Market strategy training with Reliable 15 years experience

Spare Parts Service

All RELIABLE spare parts are designed, tested and evaluated by original suppliers of raw materials, ensuring the same quality with exchanged parts. We built special warehouse for spare parts, especially serving after-sales request, making sure the swift supply of spare parts, vulnerable parts and maintenance parts.

One-Stop Purchasing Service

For your better experience, we can assist you easily purchase all the raw and auxiliary materials needed for the entire production line, including preforms, caps, glass bottles, PE film, labels, injection pellets, etc. At the same time, we can also assist you to purchase the equipment required by the factory, such as forklifts, cables, generators, boilers, air compressors and so on. We have suppliers whom we have cooperated for many years, can give you the most cost-effective sourcing experience.

PACKAGE & DELIVERY

Delivery time:

We promise the product you ordered will be delivered

30-45 days

after down payment.

WHY CHOOSE RELIABLE?

RELIABLE MACHINERY is a hi-tech machinery designing and manufacturing enterprise with 15 years

of experience, and possesses numbers of proprietary technologies . Reliable specializes in all-in-one

beverage production and packing complete lines, as well as various water filling machine.

As one of the earliest companies engaged in manufacturing liquid filling and packing equipment in China ,

we have been committing to developing other varies outstanding devices as well.

Today, RELIABLE MACHINERY is one of the top producers of quality liquid filling packing machines.

Our products include: Liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol,

plant protein drink, etc.), Barreled filling line (3-5 gallon) Water treatment system machines,

Labeling & packing machines, semi-automatic /full automatic bottle blowing machines, and

injection molding machines, etc.

RELIABLE MACHINERY also provides turn-key services for customers, from plant layout, equipment

manufacturing, production line setup, to operators training. We will carry on trying our best to meet

the demands of our customers continuously and seek for mutual development with our customers.

SERVICE &

CUSTOMER SUPPORT

At Reliable Machinery, our service department is staffed with highly-trained service technicians

capable of providing installation services on new machines as well as scheduled preventative

maintenance on your existing machinery. No matter you're looking for a single machine or

a complete liquid packaging line, RELAIBLE MACHINERY 's experienced sales staff will

work with you to find the right solution just for your liquid packaging project.

At Reliable Machinery, our service department is staffed with highly-trained service technicians

capable of providing installation services on new machines as well as scheduled preventative

maintenance on your existing machinery. No matter you're looking for a single machine or

a complete liquid packaging line, RELAIBLE MACHINERY 's experienced sales staff will

work with you to find the right solution just for your liquid packaging project.

Call us today at

+86 - (512) - 5855 0068

Mob/Whatsapp

+86-185 5118 9313

Email us at

amanda@reliable-machine.com

FAQ

|

1. What kind of manufacturer is Reliable Machinery? |

|

We Reliable Machinery is a professional industrial manufacturer, located in Zhang Jiagang City, China,

has experience in water/beverage production machinery for over 15 years.

|

|

2. What does Reliable Machinery mainly supply? What models do you have? |

|

We sincerely presents quality machinery for: liquid filling machine, gallon filling, water treatment,

bottle blowing, labeling & packing machine. We have a wide capacity range as 1000-30000 BPH

Complete Turn-Key solution for you to choose from the most suitable one.

|

|

3. How can i get the latest price? I want the best price from Reliable Machinery. |

|

Please inquiry we will provide an exclusive quotation in no time. Or share with us your ideas, we

will give you the most suitable recommendation. We promise to offer you the most cost-effective

machines.

|

|

|

|

A. Design services (layout, bottle shape, label design);

B. Engineer on-site installation & Training: ensuring machine proper operation;

C. Life-time free technical consulting service;

D. One-stop services with free spare parts service;

E. Raw materials and equipment purchase.

|

|

5. How can i check the quality of machine from Reliable Machinery? |

|

You are always welcome to visit our factory. We can also arrange a video meeting online; We can help

to arrange for visiting the model factory covering 150 countries.

|

|

6. What kind of guaranty Reliable Machinery can provide?

|

|

A. Two years warranty from installation date.

B. Two years free spare parts and fragile parts by air freight. Save your time and money. |

|

|

|

|

|

|

|

Now we have agent in Ghana, UAE, Uganda, Ethiopia… Welcome to join us!

|

If you are willing to know more about Reliable Machinery , please feel free to contact us or inquiry. We will do our best to address to your concern.

Let’s seek to success together!

Hot Searches