- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

50kw

-

Weight:

-

2500 KG

-

Dimension(L*W*H):

-

Customized

-

Year:

-

2023

-

Application:

-

Food Processing Machine

-

Product name:

-

Corn Rice Cake Making Machine Chetos Machine Puff Rice Process Machine

-

Name:

-

Snack Food Extruder

-

Usage:

-

Sancks

-

Function:

-

Extrusion

-

Keywords:

-

Snack Making Machine

-

Type:

-

Twin Screw Extruder

-

Material:

-

Food Grade Stainless Steel

-

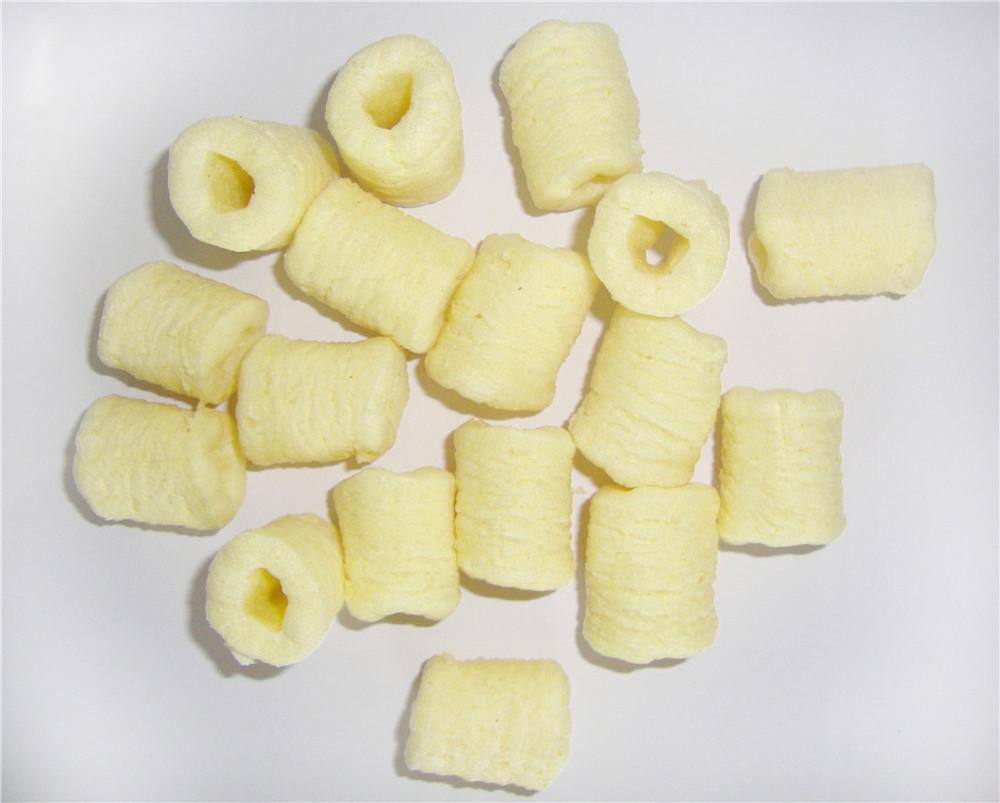

Final product:

-

Snack Pellets

-

Capacity:

-

350-1700kg

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Arrow

-

Voltage:

-

380V

-

Power:

-

50kw

-

Weight:

-

2500 KG

-

Dimension(L*W*H):

-

Customized

-

Year:

-

2023

-

Application:

-

Food Processing Machine

-

Product name:

-

Corn Rice Cake Making Machine Chetos Machine Puff Rice Process Machine

-

Name:

-

Snack Food Extruder

-

Usage:

-

Sancks

-

Function:

-

Extrusion

-

Keywords:

-

Snack Making Machine

-

Type:

-

Twin Screw Extruder

-

Material:

-

Food Grade Stainless Steel

-

Final product:

-

Snack Pellets

-

Capacity:

-

350-1700kg

Products Description

New Automatic Corn Rice Cake Making Machine Chetos Machine Puff Rice Process Machine

Shandong Arrow

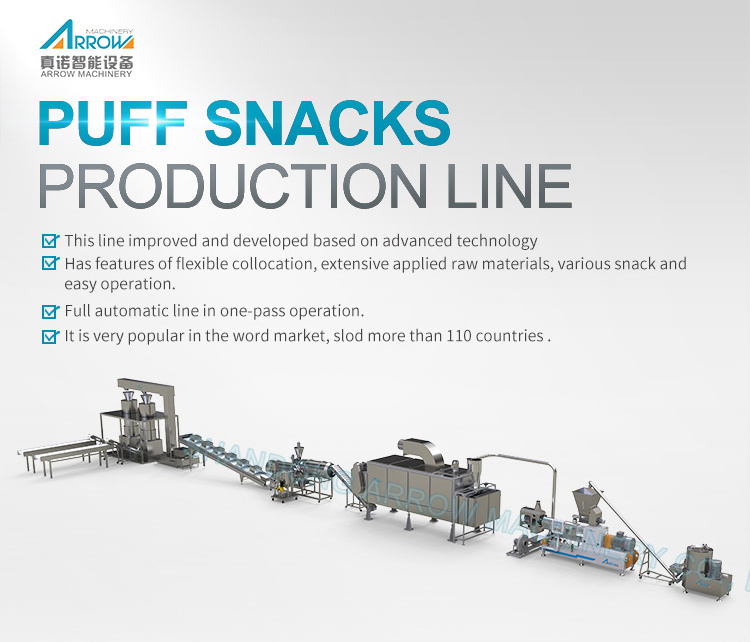

Puff snack foods production line

with "Low cost, high profits".

This processing line adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack. This

puffing snacks machine

can be used for the production all kinds of puff snacks.

Just by changing the dies or choosing suitable production process, different shapes

Corn Sticks

can be available such as ring, ball, flake, star, letter etc.

From raw material pretreatment to semi-product extruding and seasoning, we can help you design and make the whole production.

Output: 200-300KG/H, 250-450kg/h, 350-500KG/H, 300-600kg/h, 1-1.7t/h.

Custom Design Drawings

Flour Mixer→Double Screw Extruder→Double Roller Flavoring Machine→Air Conveyor

→Cooling Conveyor→Oven→Packing Machine

Arrow Snack Puff Machine production line

is highly automatic and high efficiency.

This

corn puff snacks production line

adopt twin-screw extrusion technology and are highly flexible.

Corn puff making machine

can produce various uncoated, coated or filled cereal based snacks with a wide variety of recipes and shapes.

Through mixing, extruding, cutting, drying or baking, seasoning process, delicious product will be produced.

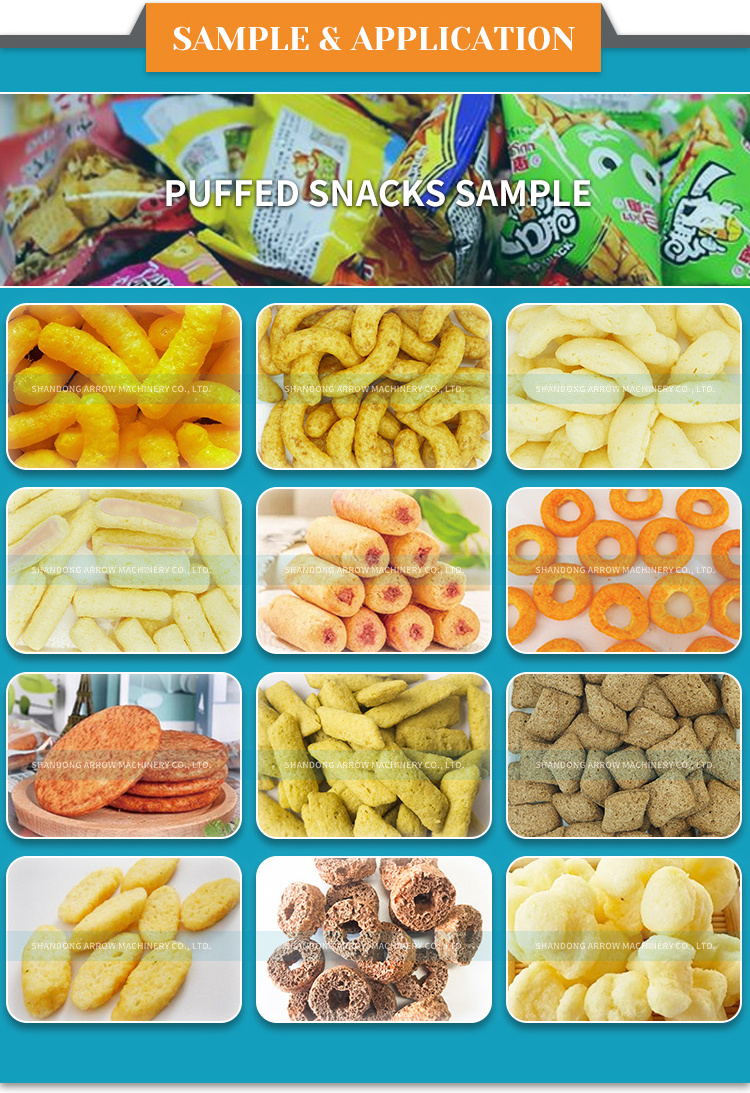

Sample & Application

Since healthy diet has got more and more attention, non-fried snack foods are popular in recent years.

Arrow Corn puff snacks production line

manufacture of extruded snacks, cereals and inclusions. Partnering with our customers and suppliers, we are able to develop extruded items in a variety of shapes and flavors.

Small-pillows, Extruded Filled Pillow Puffs, Extruded Crispy Chips, Small sticks, Extruded Snack Sticks, Small rounds, and Other Puffed Shapes: Balls, curls, bubbles, tubes, bananas, cups, disks, stars and more, we want to make your next big idea a reality.

Small-pillows, Extruded Filled Pillow Puffs, Extruded Crispy Chips, Small sticks, Extruded Snack Sticks, Small rounds, and Other Puffed Shapes: Balls, curls, bubbles, tubes, bananas, cups, disks, stars and more, we want to make your next big idea a reality.

Products Show

|

NO

|

Model

|

Screw diameter

|

Power

|

Capacity

|

|

1

|

AYT50

|

20D

|

30kw

|

70-120KG/H

|

|

2

|

AYT65

|

20D

|

37kw

|

250-450KG/H

|

|

3

|

AYT78

|

20D

|

75kw

|

300-600KG/H

|

|

4

|

AYT98

|

20D

|

132kw

|

1000-1700KG/H

|

|

5

|

AYT62

|

20D

|

90kw

|

200-300KG/H

|

|

6

|

AYT72

|

20D

|

110kw

|

350-500KG/H

|

Production line advantage

Features Of Corn Puff Snack Food Production Line

1. Easy to control by automatic production line.

2. Optional fillings for cooking makes it easy to prepare all of the raw materials.

3. Using the corn or rice mash as the raw material, having the benefit of easy to getting and low-budget.

4. No wasting from being fully utilized of the raw materials.

5. Adjustable feeding speed according to the production requirements.

6. Variety of different shape product by replacing mold easily.

7. The cutting device of the extruder has a cover to ensure safe operation.

8. Adjustable baking or drying temperature and time.

9. Equipped with the temperature display and control device.

10. Insulation device to improve thermal efficiency.

11. Optional round and rectangular product cutting machine according to the requirements.

12. The powder sprinkler feeds the seasonings with a screw, and the amount of powder can be adjusted according to the requirements.

13. Integrated, safe and hygienic seasoning drum.

14. The equipment of the whole production cycle is made of stainless steel which is hygiene and easy to clean.

Hot Searches