- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

2100*1020*1985

-

Power (kW):

-

75-160 kw

-

Weight (KG):

-

3800 KG

-

Product name:

-

Wood Pellet Machine

-

Keywords:

-

vertical ring die wood pellet machine

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Pellet size:

-

4-12mm

-

Application:

-

Make Biomass Pellets

-

Usage:

-

Biomass Energy Industry

-

Motor:

-

Electric motor, diesel engine, gasoline engine

-

Capacity:

-

3.0-4.0t/h

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

600 - 3200 kg/h

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

2100*1020*1985

-

Power (kW):

-

75-160 kw

-

Weight (KG):

-

3800 KG

-

Product name:

-

Wood Pellet Machine

-

Keywords:

-

vertical ring die wood pellet machine

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Pellet size:

-

4-12mm

-

Application:

-

Make Biomass Pellets

-

Usage:

-

Biomass Energy Industry

-

Motor:

-

Electric motor, diesel engine, gasoline engine

-

Capacity:

-

3.0-4.0t/h

Product Description

Efficiency Wood Granules Making Machine Vertical Ring Die Wood Pellet Machine Biomass Wood Pellet Machine Price

|

Model

|

Capacity(t/h)

|

|

Power(kw/h)

|

Processing specification

|

Size (mm)

|

Weight(t)

|

|

|

G420

|

crude fibre

|

0.6-0.8

|

55

|

Φ4-12

|

2100*1020*1985

|

3.0

|

|

|

G470

|

crude fibre

|

0.7-1.0

|

75

|

Φ4-12

|

2300*1100*2050

|

3.8

|

|

|

G560

|

crude fibre

|

1.0-1.5

|

90

|

Φ4-12

|

2350*1230*2300

|

6.1

|

|

|

G600

|

crude fibre

|

2.0-2.5

|

110

|

Φ4-12

|

2350*1280*2300

|

6.5

|

|

|

G680

|

crude fibre

|

2.8

|

132

|

Φ4-12

|

2900*1300*2400

|

7.3

|

|

|

G700

|

crude fibre

|

3.2

|

160

|

Φ4-12

|

2900*1450*2500

|

8.5

|

|

Biomass energy vertical ring mold pellet machine: It is the first stereotyped product carefully developed by our unit in China. It absorbs the essence of pellet machine at home and abroad, the heart parts for the "two-layer mold" assembly structure is unique;

And the "press wheel" is made of high alloy wear-resistant materials, and the life of the wearing parts is several times that of similar products: the transmission structure oil is automatically filtered and lubricated in place.

And the "press wheel" is made of high alloy wear-resistant materials, and the life of the wearing parts is several times that of similar products: the transmission structure oil is automatically filtered and lubricated in place.

It has the characteristics of unique design, reasonable structure, low consumption and high efficiency, strong wear resistance and so on to fill the gap in the vertical feeding of the domestic ring molding granulation, and reach the international advanced level.

* Biomass pellet machine are divided into

flat die

biomass pellet machines and

ring die

biomass pellet machines.

* We produce biomass pellet making line machines such as

wood logs splitter, wood logs debarker, wood chipper, hammer mill, straw bale cutter, grass cutter, mixer, dryer and cooler, pellet machine and briquette machine, pellet packing machine and conveyors

etc. , for wood pellet mill details as below

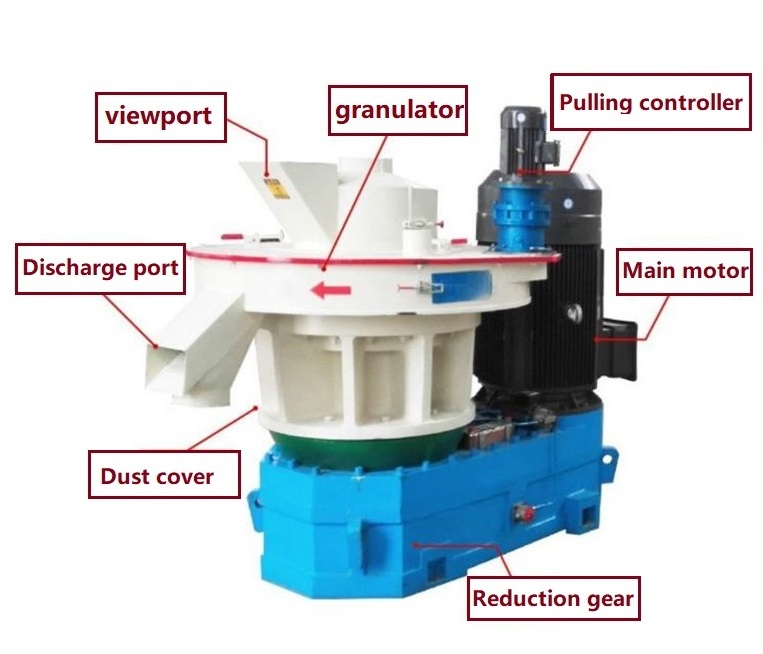

Details Images

|

Machine Feature of

Vertical Ring Die Wood Pellet Machine

|

|

|

|

1

|

Mold vertical, vertical feed, no arch, easy heat dissipation.

|

|

|

2

|

The mold is stationary, the press wheel rotates, the material is centrifugal, and the surrounding is distributed.

|

|

|

3

|

Mold two layers, double use can be, high yield and energy saving.

|

|

|

4

|

Independent lubrication, high pressure filtration, clean and smooth.

|

|

|

5

|

Independent frequency conversion device to ensure the molding rate of particles.

|

|

Product Application

Vertical Ring Die Wood Pellet Machine Materials

* For feed stuff use:

The compressed piece is suitable to be used as fuels and feedstuff of animals, such as horse, sheep, deer, pig, chicken, etc. Such machines are suitable for farms, and organic herbal medicine and chemical industry etc.

* For wood pellets use:

This series flat die pellet presses can be used for producing wood pellets. Wood pellets are made of all kinds of wood sawdust and wood waste particle.

* For biomass pellets use

Biomass pellets are made of peanut sheller, corn stalk and other biomass materials. Crushed agriculture waste including corn stalks, cotton stalks, wheat straw, rice husk, corn cob, groundnut shell,etc.

Why Choose Us

Our Machine adopt word-famous brand for the key electronic elements, pneumatic and hydraulic system to ensure high quality and reliable of the Agriculture machinery and feed machinery After the unremitting efforts of all staffs , Lvsow won the approval and trust of the customers with the excellent performance , advanced technology and good reputation.

Our machines are widely used in various fields of China and have exported to Southeast Asia, Europe, Africa, South America, Middle East Countries, and other areas. Europe technology, perfect performance. Lvsow is your reliable mechanical supplier.

We have very attractive prices and looking for oversea agents ,welcome contact us for further information and you will be surprised of the significant savings that your company can achieve by working with us.

Packing

|

Packaging Detail

|

Iron pallet or wooden cases

|

|

Delivery Detail

|

By sea or By air

|

FAQ

1. Q: Are you manufacturer of trading company?

A: We are manufacturer, also with marketing department and R&D center.

2. Q: I am newer to biomass industry, how to design the suitable plant?

A: Do not worry about that. We already helped many beginners. We provide optimal project design according to every customer’s needs.

3. Q: D What payment methods do you accept?

A1: We support various payment methods, we can accept 30% as deposit.

4.Q: How can you guarantee the after-sales service?

A: We have professional After-sales service center with experienced and skillful engineers. When problem of equipment occurs, our engineers will solve problems timely. Also spare parts can be provided timely.

A: We have professional After-sales service center with experienced and skillful engineers. When problem of equipment occurs, our engineers will solve problems timely. Also spare parts can be provided timely.

5. Q: Which kinds of raw material can be used for making pellets?

A: Sawdust (waste wood chips/shavings), other forest waste, agricultural straw, stalk, ,bamboo, peanut shells, rice husk, bagasse, alfalfa, palm fiber etc.

6. Q: What is the main process for making pellets?

A: Coarse Crushing Section(Splitter, Wood Chipper)—Drying Section—Crushing Section—Pelletizing Section—Cooling Section—Packing Section

Hot Searches