- Product Details

- {{item.text}}

Quick Details

-

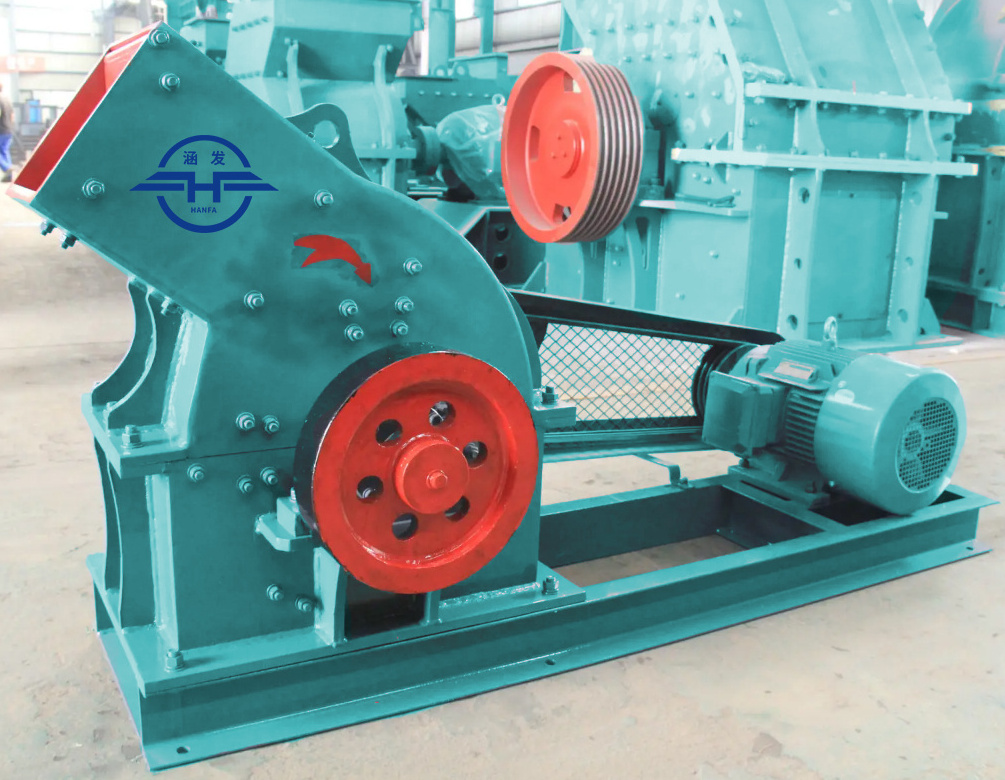

Brand Name:

-

HANFA

-

Dimension(L*W*H):

-

2818*2100*2391mm

-

Weight:

-

8000 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Hammer Crusher

-

Model:

-

PCZ1308

-

Color:

-

Customerized

-

Max feeding size:

-

600mm

-

Power(kw):

-

4P 132

-

After sale Service:

-

Life-long Service

-

Advantage:

-

High Effiency

-

Spare parts supply:

-

Lifelong Time

-

Installation:

-

Under Engineer's Guide

Quick Details

-

Application:

-

Mining, Construction

-

Capacity(t/h):

-

100-180, 100-180

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HANFA

-

Dimension(L*W*H):

-

2818*2100*2391mm

-

Weight:

-

8000 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Hammer Crusher

-

Model:

-

PCZ1308

-

Color:

-

Customerized

-

Max feeding size:

-

600mm

-

Power(kw):

-

4P 132

-

After sale Service:

-

Life-long Service

-

Advantage:

-

High Effiency

-

Spare parts supply:

-

Lifelong Time

-

Installation:

-

Under Engineer's Guide

Product Description

Scope of application

Hammer crusher is a one-stage crusher that directly crushes materials with a particle size of 600-1800 mm to below 25 or 25 mm. Hammer crusher is suitable for crushing medium hardness materials, such as limestone, slag, coke, coal and other materials in the cement, chemical, electric power, metallurgy and other industrial sectors for medium and fine crushing operations.

Specification

Technical Parameter

|

|

|

|

|

|

|

|||||||

|

Model

|

Rotor diameter×length(mm)

|

Feed opening Length×width(mm)

|

Feeding size(mm)

|

Capacity(t/h)

|

Power(kw)

|

Overall dimension(L×W×H)(mm)

|

||||||

|

PCZ1308

|

1300x1000

|

930x650

|

≤600

|

100-180

|

4P 132

|

2818x2100x2391

|

||||||

|

PCZ1410

|

1400x1000

|

1020x750

|

≤700

|

180-230

|

4P 160/90x2

|

2830x2100x2485

|

||||||

|

PCZ1610

|

1600x1000

|

1150x1000

|

≤900

|

260-350

|

4P 220-250/132x2

|

3370x2415x2751

|

||||||

|

PCZ1615

|

1600x1500

|

1400x1000

|

≤900

|

380-550

|

4P 355-400/200x2

|

3371x2925x2752

|

||||||

|

PCZ1716

|

1700x1600

|

1640x1300

|

≤1200

|

600-1100

|

4P 250x2

|

3520x3000x3210

|

||||||

|

PCZ1720

|

1700x2000

|

1980x1300

|

≤1200

|

800-1200

|

4P 400x2

|

3670x3390x3328

|

||||||

|

PCZ1920

|

1900x2000

|

1850x1600

|

≤1500

|

900-1500

|

2x500

|

3729x3300x4451

|

||||||

|

PCZ2225

|

2200x2500

|

2100x2300

|

≤1700

|

2000-2600

|

1250

|

3931x4100x4660

|

||||||

Working Principle

The rotor is rotated by the motor and v-belt, and the hammers are stretched out in all directions by the centrifugal force generated during the rotation, and the large pieces of material are crushed by the hammers moving at high speed after entering the crushing chamber through the feed opening. The crushed material is discharged by the castor bar with a gap in the lower part, while the unqualified material is left in the crushing cavity and is repeatedly acted upon by the hammers and the iron block until it can be discharged.

Product Structure

Product Advantages

2. There is no screen grate bottom, there is no requirement for the moisture content of the material, there is no problem of sticking and blocking the sieve plate, and there is no problem that the material cannot be discharged in time and repeatedly crushed; the structure seal of the hammer is broken, which solves the dust pollution in the crushing workshop. and body leakage problems.

3. The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.

4. The bearing box is all made of cast steel and fixed with four screws, which is scientific and practical; the working hammer head is cast by new technology, which is wear-resistant and impact-resistant.

1. The crushing ratio is large, the production efficiency is high, and the applicability is strong. The required particle size can be adjusted according to customer requirements.

2. There is no screen grate bottom, there is no requirement for the moisture content of the material, there is no problem of sticking and blocking the sieve plate, and there is no problem that the material cannot be discharged in time and repeatedly crushed; the structure seal of the hammer is broken, which solves the dust pollution in the crushing workshop. and body leakage problems.

3. The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.

4. The bearing box is all made of cast steel and fixed with four screws, which is scientific and practical; the working hammer head is cast by new technology, which is wear-resistant and impact-resistant.

Applications

Widely used in industrial sectors such as cement, chemical industry, electric power, and metallurgy.

Applicable Materials

The hammer crusher is suitable for crushing medium hardness materials such as limestone, slag, coke, coal and other materials in medium and fine crushing operations in cement, chemical, electric power, metallurgy and other industrial sectors.

If you need our products, please contact us, this is my WhatsApp. Or you can directly click the blue font below to send an inquiry, we will help you make more money.

WhatsApp:+8617739786040

WhatsApp:+8617739786040

Hot Searches