- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

10 - 8000

-

Spindle Taper:

-

BT40-120

-

Repeatability (X/Y/Z) (mm):

-

0.002

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

R&C

-

Model Number:

-

VMC cnc milling machine

-

Table Travel (mm):

-

800/400

-

Year:

-

2017

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500X2100X2360

-

Weight (KG):

-

5200

-

Spindle Motor Power(kW):

-

11/15

-

Max. Table Load(kg):

-

450 kg

-

CNC or Not:

-

CNC 5 axis small milling machine

-

Mini Milling Machine Name:

-

VMC650 vertical machining center 5 axis cnc milling machine

-

Small Machining Center Type:

-

Mini Metal CNC Milling Machine

-

Product name:

-

cnc milling machine 4 axis

-

Spindle Speed:

-

8000rpm(Optional:10000 ) 4 axis cnc metal milling machine

-

Mini Metal Milling Machine Usage::

-

Metal Parts Machining Center

-

Product number::

-

VMC650 vertical machining center 5 axis cnc milling machine

-

Controlling Mode::

-

Cnc Control Vertical Machining Center

-

Vertical cnc milling machine Type::

-

Vertical CNC Milling Machining Center

-

cheap cnc milling machine name::

-

Vertical Milling Machining Center

Quick Details

-

Table Travel (X) (mm):

-

650 mm

-

Table Travel (Y) (mm):

-

400 mm

-

Table Travel (Z) (mm):

-

500 mm

-

Range of Spindle Speed(r.p.m):

-

10 - 8000

-

Spindle Taper:

-

BT40-120

-

Repeatability (X/Y/Z) (mm):

-

0.002

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

R&C

-

Model Number:

-

VMC cnc milling machine

-

Table Travel (mm):

-

800/400

-

Year:

-

2017

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500X2100X2360

-

Weight (KG):

-

5200

-

Spindle Motor Power(kW):

-

11/15

-

Max. Table Load(kg):

-

450 kg

-

CNC or Not:

-

CNC 5 axis small milling machine

-

Mini Milling Machine Name:

-

VMC650 vertical machining center 5 axis cnc milling machine

-

Small Machining Center Type:

-

Mini Metal CNC Milling Machine

-

Product name:

-

cnc milling machine 4 axis

-

Spindle Speed:

-

8000rpm(Optional:10000 ) 4 axis cnc metal milling machine

-

Mini Metal Milling Machine Usage::

-

Metal Parts Machining Center

-

Product number::

-

VMC650 vertical machining center 5 axis cnc milling machine

-

Controlling Mode::

-

Cnc Control Vertical Machining Center

-

Vertical cnc milling machine Type::

-

Vertical CNC Milling Machining Center

-

cheap cnc milling machine name::

-

Vertical Milling Machining Center

Product Description

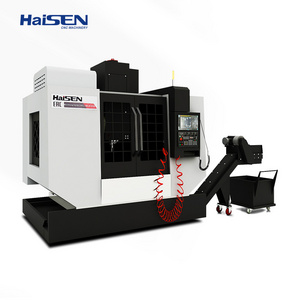

5 axis CNC Small Vertical Machining Center Vmc650 VMC 650 Cnc Mini Metal Milling Machine

Vertical CNC Milling Machine Center

Tool System:

Automatic toolchanger is composed of tool magazine and tool changing arms. Automatic toolchanger is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic toolchanger and other reasons on precision. Tool selection adopts the method of fixe address in the shortest path All tools retum to origine position, therefore, the problem of collsion between large-size tools is only considered in initial installation Two-way tool magazine adopts the shortest path.

Hardware configuration:

Axis of control: x, Y, Z of the three coordinate axis and a spindle.

Number of axis: X, Y, Z three axis linkage.

Operation panel:full function cnc keyboard.

The man-machine communication interface standard configuration: PCU50.

Input and output module: separation type through the IM361 interface module expansion of the 57-300 input and output module.

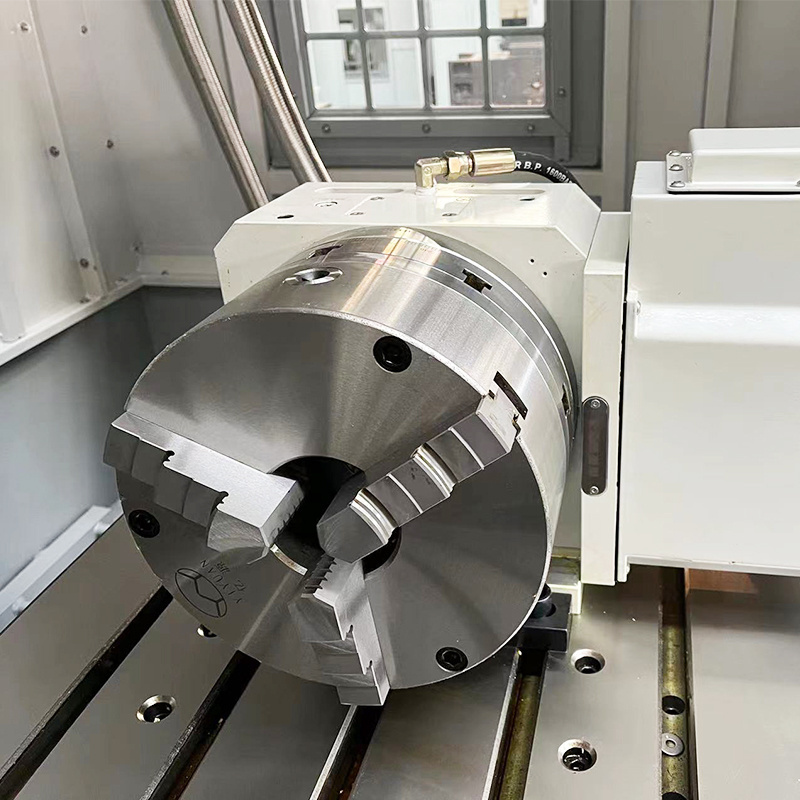

Strong spindle, ensure perfect processing:

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.

By enlarging thickness and diameter of spindle ends and flanges, the spindle with roller bearing not only strengthens all factors related to spindle system, but also improves cutting perormance via clamping force of powerful tools.

Win in power:

Optional spindle:

BT40:10000rmin Belt-drive

12000,15000/min Direct-drive

BT50:6000r/min Belt-drive

Application:

This VMC is suitable for mechanical processing and mold making .And it can adapt to the processing

requirement from rough machining to finish machining .It can also finish many working procedures like milling ,drilling ,tapping,boring ,etc.

|

Model

|

VMC650 (GSK25i system)

|

VMC640 (GSK25i system)

|

|

Travel parameters of 3 axis

|

|

|

|

X axis travel

|

650mm

|

600mm

|

|

Y axis travel

|

450mm

|

400mm

|

|

Z axis travel

|

500mm

|

450mm

|

|

X/Y/Z Motor Torque

|

11/11/15N.m

|

8/8/15N.m

|

|

Spindle face to table distance

|

120-620mm

|

80-530mm

|

|

Distance between spindle center and column guide surface

|

500mm

|

350mm

|

|

Worktable parameters

|

|

|

|

Worktable size

|

900×400mm

|

800×320mm

|

|

Maximum load bearing of worktable

|

400kg

|

400kg

|

|

T Shot

|

3×18×110mm

|

3×16×110mm

|

|

Feeding parameters

|

|

|

|

X/Y/Z axis rapid movement rate

|

20/20/18 m/min

|

24/24/16 m/min

|

|

Feed moving velocity X, Y, Z

|

1-10m/min

|

1-10m/min

|

|

Spindle parameters

|

|

|

|

Main shaft connection

|

Belt

|

Belt

|

|

Spindle taper

|

BT40-120

|

BT40-120

|

|

Range of spindle speed

|

8000rpm(Optional:10000 )

|

8000rpm(Optional:10000 )

|

|

Spindle motor power

|

5.5KW (Optional:7.5KW )

|

3.7KW (Optional:5.5KW )

|

|

ATC paremeters

|

|

|

|

ATC capacity

|

16qty

|

12qty

|

|

Maximum tool size

|

Φ80mm(tool from a distance)

|

Φ92mm(tool from a distance)

|

|

Maximum tool weight

|

7kg

|

5kg

|

|

Precision

|

|

|

|

PositionaI accuracy(JIS standard)

|

±0.008/300mm

|

≤0.02mm

|

|

Repeated positioning accuracy(JIS standard)

|

±0.005mm

|

±0.008/300mm

|

|

Shape and weight

|

|

±0.005mm

|

|

Machine size

|

2300×2200×2400mm

|

2600×1950×2400mm

|

|

Weight

|

3800kg

|

3000kg

|

Recommend Products

Details Display

Optional Configurations

Hot Searches