- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4000*900*1600mm

-

Weight (KG):

-

1500 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Product name:

-

Edge Banding Trimming Machine with PVC Tape

-

Application:

-

Kitchen cabinet, wardrobe, office table, etc. wood working

-

Keywords:

-

Full-automatic Edge Banding Machine

-

Feed speed:

-

8-20m/min

-

Optional function:

-

Premilling, Corner Trimming

-

Workpiece thickness:

-

10-60mm

-

Workpiece width:

-

≥60mm

-

Workpiece length:

-

≥100mm

-

Total Power:

-

15w

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

4000*900*1600mm

-

Weight (KG):

-

1500 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Product name:

-

Edge Banding Trimming Machine with PVC Tape

-

Application:

-

Kitchen cabinet, wardrobe, office table, etc. wood working

-

Keywords:

-

Full-automatic Edge Banding Machine

-

Feed speed:

-

8-20m/min

-

Optional function:

-

Premilling, Corner Trimming

-

Workpiece thickness:

-

10-60mm

-

Workpiece width:

-

≥60mm

-

Workpiece length:

-

≥100mm

-

Total Power:

-

15w

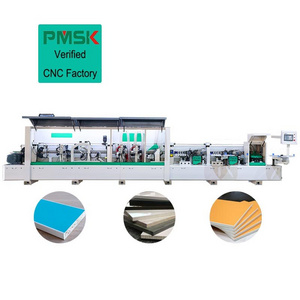

Wood Edge Banding Trimming Machine with PVC Tape and Manufacturing Production Line Roller

|

MODEL |

Parameter |

|

Panel Thickness |

10-60mm |

|

Panel Length |

≥150mm |

|

Panel Width |

≥80mm |

|

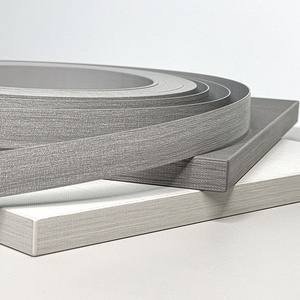

Edge Thickness |

0.4-3mm |

|

Feed Speed |

12,16,20m/min |

|

Working Pressure |

0.6MPa |

|

Total Power |

14.5kw |

|

Overall Size |

5400x1000x1600mm |

|

Weight |

1500kg |

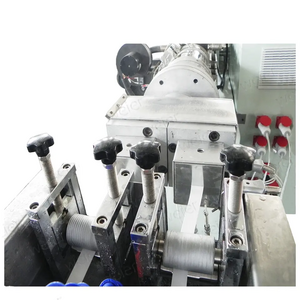

1. Pre-milling system

2. Gluing system

3. Feeding and edge cutting system

4. Press system

5. End trimming system

6. Rough trimming system

7. Fine trimming system

8. Corner trimming system

9. Scrapping system

10. Flat scraping system

11.Hogging system

1.no leakage of glue. Because of the transmission reason, the rubber seal will cause leakage after being damaged, which will affect the normal operation of the machine. There is no problem of leakage in the gluing tank.

2. the sol is not aging. The problem of adhesive quality is affected by the residual glue in the plastic tank, and the quality of the adhesive is affected by many times.

3. Easy to clean. The machine can be cleaned regularly, the gluing tank can be more convenient than the plastic tank, and even can be cleaned without stopping.

4.The failure is few. The machine is in high quality. It has few problems, which brings a lot of convenience to the users.

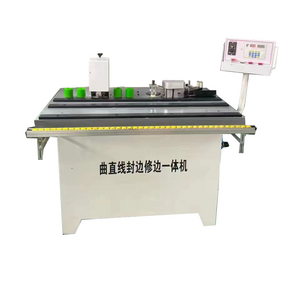

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc, straight line edging and trimming. Function: pre-milling,gluing,edge cutting,end trimming, rough trimming, fine trimming, corner trimming, scraping, buffing, slotting and so on. Edging smoothly and edging line is straight. The machine is stable, reliable and durable, with favorable price. It is especially suitable for large and medium-sized furniture manufacturers.

Jinan GoodCut CNC Machinery Co.,Ltd. GoodCut has Purchasing department, The design department, The production department, Quality inspection department, packaging and transportation department, The sales department, After sales service department. We can offer highest quality machine, and competitive price.

Mainly manufacture and sale cnc router, laser engraving, marking, cutting machine, wood lathe machine, fiber cutting machine, plasma cutting machine, 3D scanner etc.

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 500 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.