- Product Details

- {{item.text}}

Quick Details

-

Ink Type:

-

Reactive, sublimation, pigment

-

Place of Origin:

-

Zhejiang, China

-

After-sales Service Provided:

-

Online support, Free spare parts

-

Product name:

-

Digital textile direct fabric printing machine

-

Print head:

-

Double DX5

-

Production printing speed:

-

30 square meters/hour

-

Power rate::

-

6KW

-

RIP software:

-

Wasatch/ Neostampa optional

-

Ink type:

-

Reactive, Pigment or sublimation inks.

-

Power supply:

-

2 phases/3 phases optional

-

Packing size/weight:

-

3370*1420*1420mm/1200KGS

-

Print head height:

-

2-30mm adjustable

-

Application:

-

Fabric printing machine for all fabrics including knit fabric

-

Certification:

-

CE Certification

Quick Details

-

Print Dimension:

-

1.6*500

-

Condition:

-

New

-

Color & Page:

-

Fabric printing machine for multicolor printing on fabric

-

Ink Type:

-

Reactive, sublimation, pigment

-

Place of Origin:

-

Zhejiang, China

-

After-sales Service Provided:

-

Online support, Free spare parts

-

Product name:

-

Digital textile direct fabric printing machine

-

Print head:

-

Double DX5

-

Production printing speed:

-

30 square meters/hour

-

Power rate::

-

6KW

-

RIP software:

-

Wasatch/ Neostampa optional

-

Ink type:

-

Reactive, Pigment or sublimation inks.

-

Power supply:

-

2 phases/3 phases optional

-

Packing size/weight:

-

3370*1420*1420mm/1200KGS

-

Print head height:

-

2-30mm adjustable

-

Application:

-

Fabric printing machine for all fabrics including knit fabric

-

Certification:

-

CE Certification

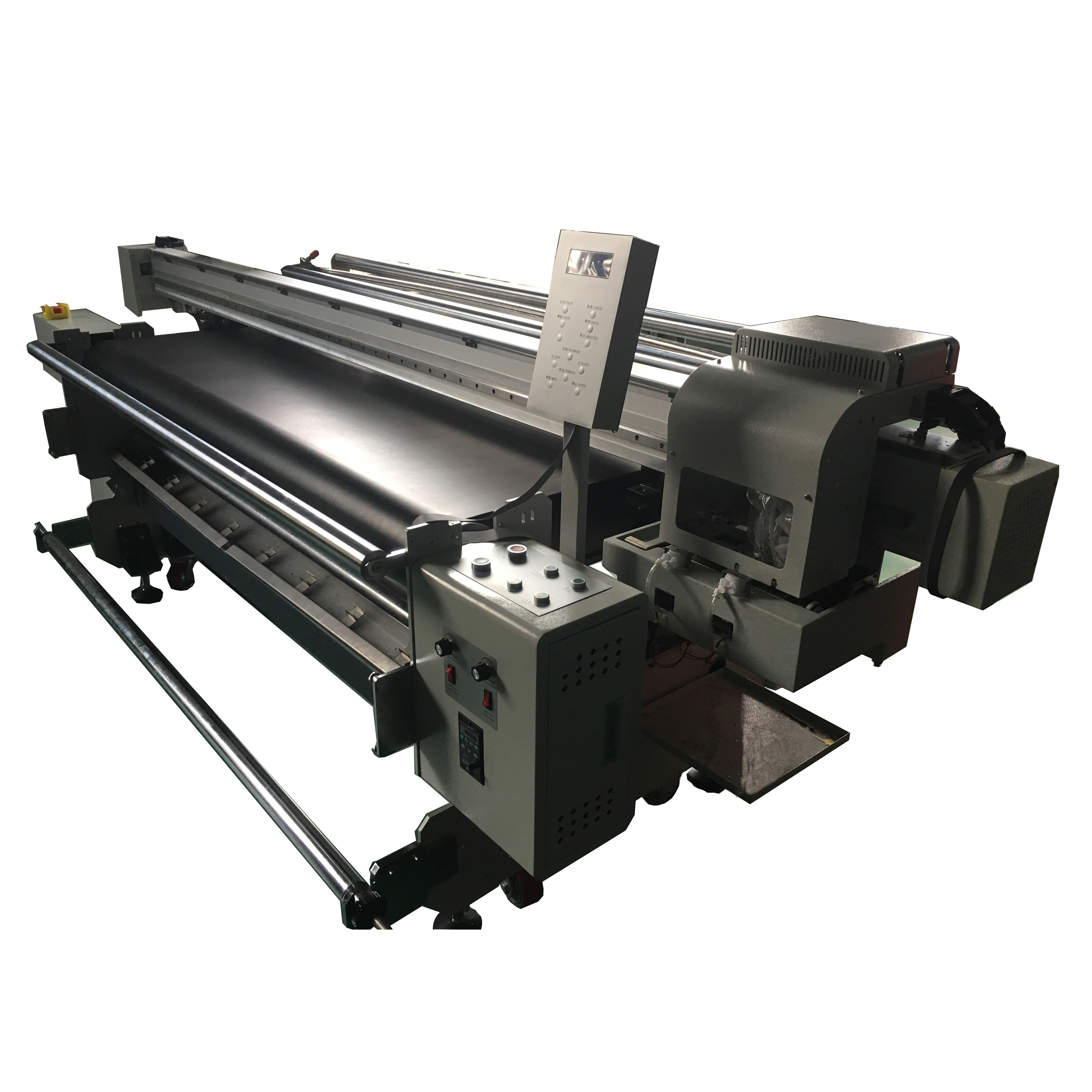

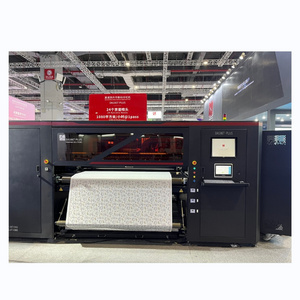

Digital textile direct fabric printing machine

1. The fabric printing machine is designed for industrial production.

2. Very low cost so that most textile printing factory can afford it.

3. This fabric printing machine technology are well accepted by local printing factories.

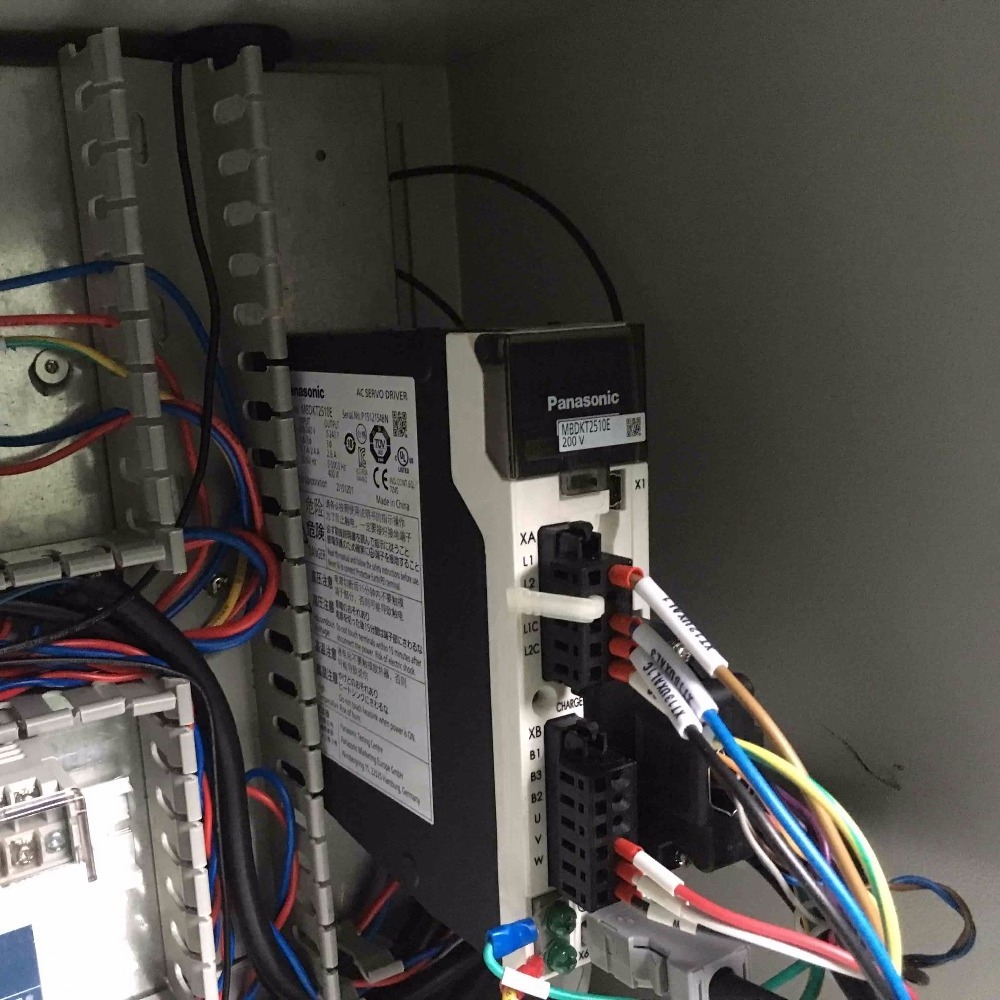

4. Top brand parts be used in building the textile fabric printing machine.

5. Not only the fabric printing machine, but also provide consultant service on digital fabric printing process.

The Digital textile direct fabric printing machine is designed by experienced professional engineer who used to work for Atexco which is the leader for digital textile printer research in China. After accumulated rich experience in the front runner enterprise, his masterpiece textile printer combined many advantages like economical in cost, easy but functional structure to make the belt running straight in feeding fabric, all top brands parts be used to build the textile printer in key important parts.

1. Our motto is that real production is the only way to approve quality. We checked all textile fabric printing machine working in end-user factories before marketing them. So we also provide the service to check the machine working conditions if you are interesting in. Or you can request to have some videos before visiting.

2. We only work with original textil fabric printing machine developers. So you will get best price, no quality worry and continuous follow-up after-sales services.

3. The most important thing is that you will enjoy top level consultant team for all the digital textile printing problem you might met which is far more important factor for your textile printing business.

| Textile fabric printing machine model | ABS-1800 |

| Print head | 2 DX5 |

| Workable fabric thickness | 2-30mm adjustable |

| Maximum fabric printing width | 1800mm |

| Maximum fabric width | 1850mm |

| Workable fabric type | Knit or Woven cotton, linen, silk, wool, polyester, nylon |

| Textile printing machine ink type | Reactive, disperse, sublimation, pigment or acid inks |

| Ink color | Black, Cyan, Megenta, Yellow, Lc, Lm, Grey, Red, Orange, Blue optional |

| Production printing speed | 30 square meters/hour |

| Image type | JPEG/TIFF/BMP, RGB/CMYK color mode |

| RIP software | Wasatch/Neostampa |

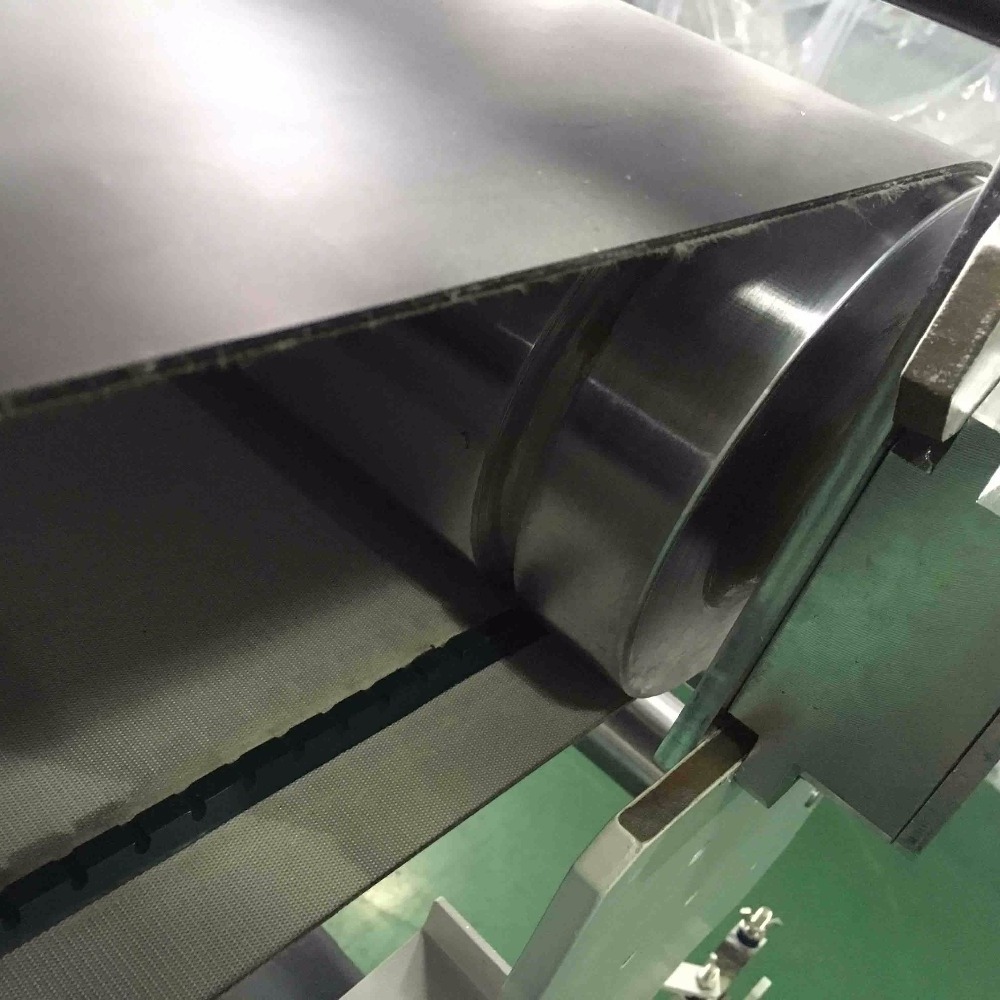

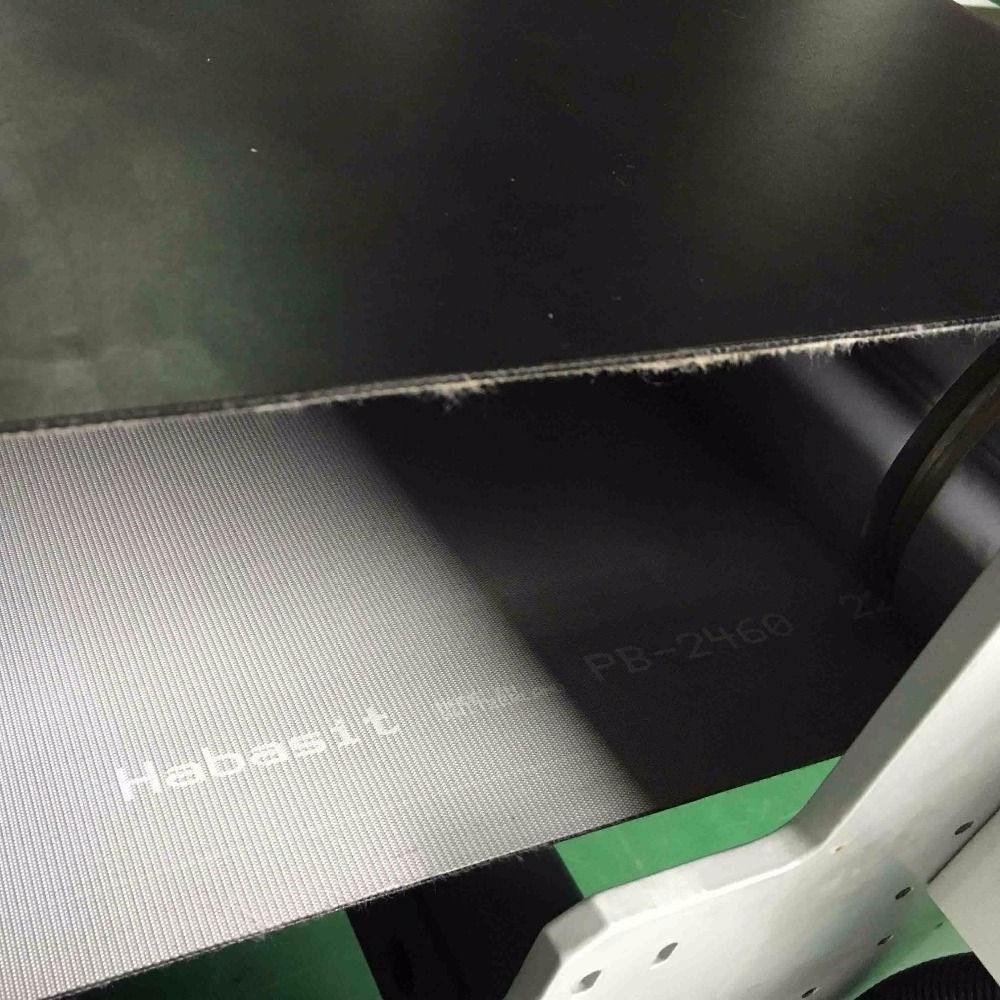

| Textile printer feeding system | Continuous sticky belt feeding system with belt washer, take up. |

| Textile printer power rate | 6KW |

| Power supply | 220V 50HZ, 2 phase/ 380V 50HZ, 3 phase optional |

| Air compressor | Air volume ≥ 0.3 m³/min, Air pressure ≥ 6KG |

| Textile printer working condition | Temperature: 20-30°, Moisture: 60%-80% |

| Textile printing machine size | 3350mm*1400mm*1400mm |

| Weight of textile printer | 700KGS |

1. Can 5113 print-head also be used to print reactive inks?

No. Sublimation inks works fine on 5113 print head. But reactive inks still damage the 5113 print head.

2. What kind of print head is the best for the digital textile printing?

It is good question. Everyone got his own understanding on it. But it can be devided into two kinds in general. One is regarded as industrial print head level like Kyocera, Seiko, Spectra, Ricoh, Konica etc. This kind of heads are famous for the longer life span and faster printing speed. But fewer nozzles, fewer channels, and bigger ink drops. The other is regarded as Epson DX5, DX7 and 5113. Especially the DX5 head, it is the most popular head on the market. It is famous for the cheap price, smaller ink drop size and fine printing result. Almost all kinds of inks is compatible to this head. The price is very favourable when you calculate into each nozzle. Most printing factories are relying on DX5 to earn their profit in China up till the 27th, June 2016.

3. Do you also support the coating agent formula if we buy your machine?

Yes. We provide full support for all digital textile printing process from fabric coating, digital textile printing, steaming curing, washing. The pre treatment and post treatment machine factory professional will also provide relative support to you. You can check the pre-coating machine, textile steaming machine and washing machine here.

4. Do you also sell quality inks?

Yes. We will recommend customer to use the inks which our local customer had approved it. Of course, if buyers got his own channel in domestic market, the buyers can use their own inks.

5. How to make the after sale service since oversea buying?

The buyer can consult us online if there is any question in machine running. We will give some points for buyers to check. And we will send parts for replacement to solve problem. Normally problem can be solved in this way. Just in case, if the buyer can not solve the problem by online supporting. We can send technician to site if the buyers can cover the costs. There was no such problems occurs while we got 50 machines running all over the world for 3 years up till the 27th, June 2016.

6. If there is problem occured when the buyer can not judge the real cause, how to deal with it?

We got full experienced team who specialized in pre-treatment, digital printing to post treatment untill finishing treatment. So we are able to provide the full service in digital textile printing machine fields. Our expert will find out the actually reason.