Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

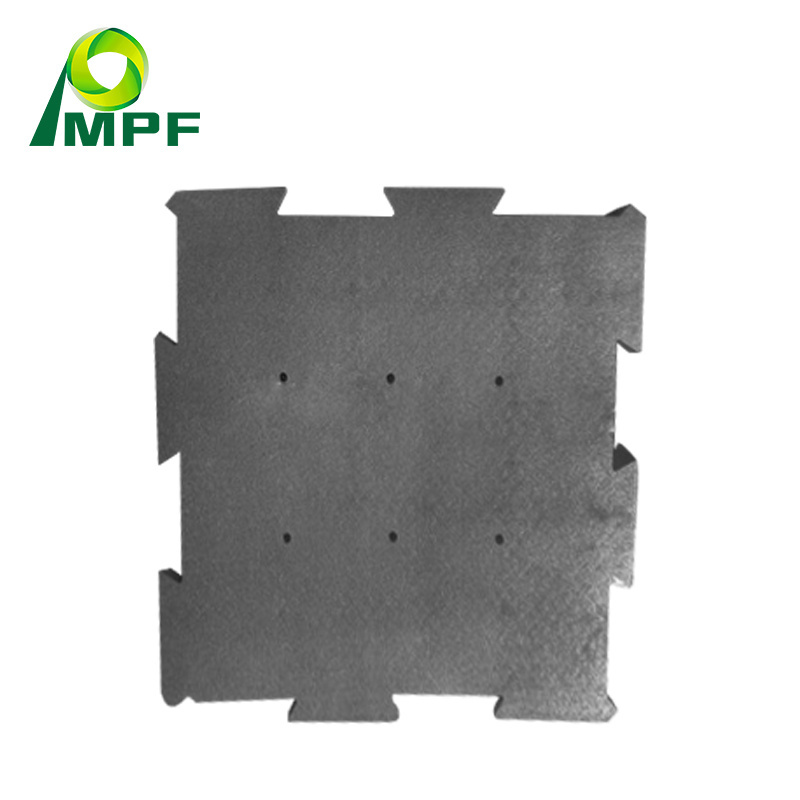

Model Number:

-

PP-tile

-

Application:

-

Football Field underlay

-

Product Name:

-

Interlocking EPP Sports Flooring

-

Certificate:

-

Labosport

-

Material:

-

Expanded Polypropylene(EPP)

-

Usage:

-

Synthetic Court

-

Backing:

-

PP+NET+SBR GLUE

-

Packing:

-

In polybag

-

Density:

-

30g/L

-

Product name:

-

play EPP foam shockpad

Quick Details

-

Color:

-

black, Black and white

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PMPF

-

Model Number:

-

PP-tile

-

Application:

-

Football Field underlay

-

Product Name:

-

Interlocking EPP Sports Flooring

-

Certificate:

-

Labosport

-

Material:

-

Expanded Polypropylene(EPP)

-

Usage:

-

Synthetic Court

-

Backing:

-

PP+NET+SBR GLUE

-

Packing:

-

In polybag

-

Density:

-

30g/L

-

Product name:

-

play EPP foam shockpad

EPP (Expanded Polypropylene) is a highly versatile closed-cell bead foam that provides a unique range of properties, including outstanding energy absorption, multiple impact resistance, thermal insulation, buoyancy, water and chemical resistance, exceptionally high strength to weight ratio and 100% recyclability.

We are China leading OEM factory for moulded EPP(Expanded Polypropylene) foam products, the products are customized made according to the customers provided design and need to make moulds for production. Our EPP foam moulded products are widely used in the packaging industry, automotive parts industry, toys industry, sports safety protection industry, building HVAC industry, cold chain food delivery industry and heating insulation industry, etc.

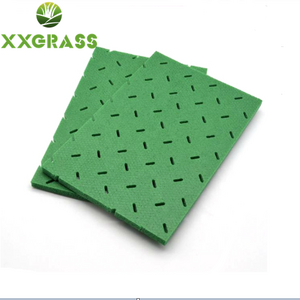

-High resilience following static and dynamic loading

-Unchanged energy absorption after repeated impact loading

-Isotropic deformation performance, independent of the direction of impact

-Negligible water absorption

-Functions reliably over a wide range of temperatures

-Good resistance to chemicals and oils

-Molding density adjustable to meet specific requirements

-Good heat insulating properties

-Easy to clean and sterilize

-Environmentally friendly and can be recycled in a variety of ways

-Free from propellant gases and other chemical blowing agents

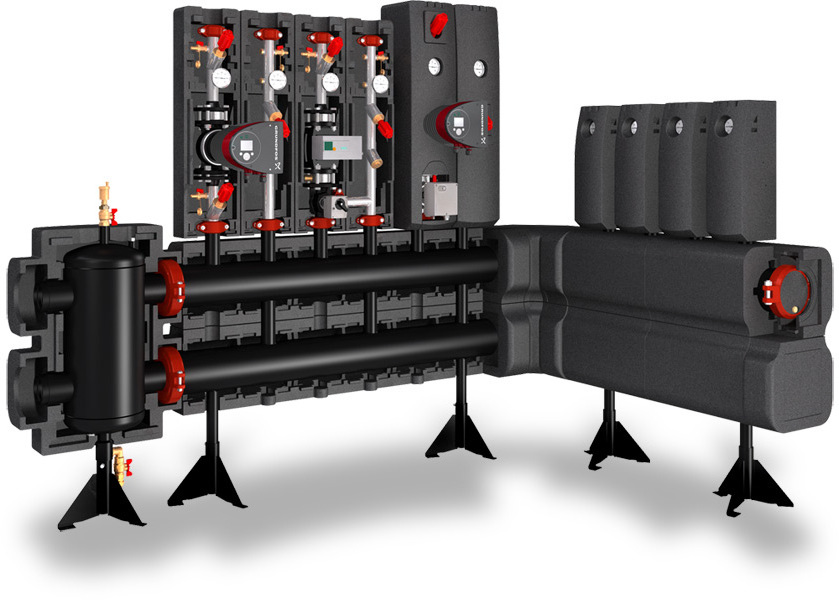

In the heating and air conditioning sector, EPP moldings are used to create energy-efficient solutions. With their excellent insulating properties, EPP moldings prevent the uncontrolled loss of thermal energy in heating systems. As insulation for pumps, boilers and heating controllers, EPP housings ensure that your water stays hot longer. Due to the special design with plug or click connections, the devices remain easily accessible for maintenance and repair.EPP offers exactly the right properties for HVAC applications (heating, ventilation, air conditioning). The low weight makes housing parts made of EPP light and easy to use installation elements. Thus, faster assembly and disassembly can be guaranteed by practical click systems. These also ensure easy and quick access for maintenance work. The efficient heat and noise insulation of EPP makes it a profitable material for many HVAC applications such as pumps, compressors and air conditioning units.

EPP molded parts as packaging and EPP dunnage trays are used during transport to reliably protect sensitive and valuable goods. Especially EPP has an excellent shock resistance and resilience. And can thus be used several times as packaging and dunnage trays.The DUANG GROUP PMPF factory manufactures EPP packaging and EPP containers precisely according to the needs of the customers. EPP has excellent shock resistance and very good resilience. Especially for packaging and containers made of EPP, this means a high added value through reusability. In addition, EPP has a high temperature and chemical resistance. EPP containers and EPP packaging are also approved for direct contact with food. Like Styrofoam and other particle foams, EPP is also 100% recyclable. Do you need a cold chain solution with EPP container or EPP packaging?

The demands on the materials used in the sports and leisure sector are very high. Aspects such as resilience and impact resistance are characteristic of high-quality sports articles. For this reason, sports product manufacturers increasingly resort to the particle foam EPP. Thus, fascia rolls and balls or drones and model planes are made of EPP. Many sports and leisure products and toy products today make use of the positive properties of EPP particle foam.

EPP is resistant, robust and has a high energy absorption. Accordingly, expanded polypropylene (EPP) is extremely suitable for products and moulded parts that are subject to mechanical stress. EPP is particularly popular as a crash pad, bumper or headrest in motor vehicles. Compared to other materials, EPP is very light. This saves weight in the automobile, which leads to lower fuel consumption and greater environmental friendliness. EPP is 100% recyclable. But EPP is not only a valuable and practical material for the automotive industry. EPP can be used in almost all industries where lightweight construction potential, insulation and resistance are important aspects.

PMPF company is one of the leading manufacturer of EPP-moulded components for automotive parts, we have good experience and technology in the expanded foam moulding industry, our factory is ISO/TS 16949:2009 Automotive Components standard and ISO 14001:2004 Environmental standard certified. We are dedicated to manufacture lightweight EPP molded products.