1)Into bottle way is air conveyor direct connection with Bottle dial2)All 304/316 stainless steel rinse heads, water spray style

inject design, more save water consumption and more clean

3)304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

4)304/316 stainless steel washing pump make the machine more durable

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

100%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIEDE

-

Dimension(L*W*H):

-

2100x1800x2200

-

Weight:

-

3000 KG

-

Product Name:

-

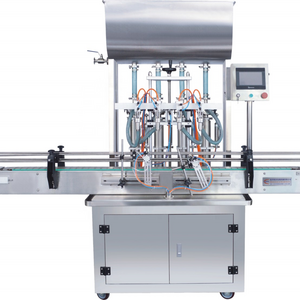

Mineral water bottle filling machine

-

Function:

-

Washing Filling Capping

-

Filling material:

-

Flowing Liquid

-

Product name:

-

3in1 Automatic Bottle Washing Filling Capping Machine

-

Bottle type:

-

PET Plastic Bottle,small square bottle,glass bottle

-

Material:

-

SUS 304

-

Capacity:

-

6000BPH

-

Usage:

-

water filling

-

Processing Types:

-

Normal Pressure Filling

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Juice

-

Filling Accuracy:

-

100%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIEDE

-

Dimension(L*W*H):

-

2100x1800x2200

-

Weight:

-

3000 KG

-

Product Name:

-

Mineral water bottle filling machine

-

Function:

-

Washing Filling Capping

-

Filling material:

-

Flowing Liquid

-

Product name:

-

3in1 Automatic Bottle Washing Filling Capping Machine

-

Bottle type:

-

PET Plastic Bottle,small square bottle,glass bottle

-

Material:

-

SUS 304

-

Capacity:

-

6000BPH

-

Usage:

-

water filling

-

Processing Types:

-

Normal Pressure Filling

Product Description

Automatic bottled drinking water making equipment / pure water bottling machine / mineral water filling plant price

This CGF Wash-filling-capping 3-in-1 unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water,alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and capping, it can reduce the materials and outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Filling Machine Benefits

1) The machine is mainly used for PET bottled non-carbonated beverage production line,such as spring water and wine drinks

2) Washing,filling and capping are available in one machine

3) The contact time between raw materials and the outside world has been reduced to improve the health conditions, production capacity and economic benefits

4) The structure of conveying is hanging type and clamping the bottleneck to easily change bottle type

5 )Using the advanced PLC(Programmable Logic Controller) technology

6) The major electrical apparatus are all products of well-known brands, such as SIEMENS, MITSUBISHI, Schneider and OMRON

7) Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

8) Optimum uptime: 30 % reduction in changeover and maintenance downtime

9) Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

10) Hygiene improvement through volume control and contactless filling

11) Automatic dump bottles: Safer, easier cleaning procedures

12) Automatic bottle changeover improves uptime

2) Washing,filling and capping are available in one machine

3) The contact time between raw materials and the outside world has been reduced to improve the health conditions, production capacity and economic benefits

4) The structure of conveying is hanging type and clamping the bottleneck to easily change bottle type

5 )Using the advanced PLC(Programmable Logic Controller) technology

6) The major electrical apparatus are all products of well-known brands, such as SIEMENS, MITSUBISHI, Schneider and OMRON

7) Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

8) Optimum uptime: 30 % reduction in changeover and maintenance downtime

9) Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

10) Hygiene improvement through volume control and contactless filling

11) Automatic dump bottles: Safer, easier cleaning procedures

12) Automatic bottle changeover improves uptime

|

Mold

|

CGF8-8-3

|

CGF14-12-5

|

CGF16-16-6

|

CGF18-18-6

|

CGF24-24-8

|

CGF32-32-10

|

CGF40-40-12

|

CGF50-50-15

|

CGF60-60-15

|

||||||||

|

Production capacity(B/H)

|

1000-2000

|

2000-3500

|

3500-5000

|

5000-7000

|

7000-12000

|

12000-15000

|

15000-20000

|

20000-24000

|

24000-30000

|

||||||||

|

Suitable bottle shape

|

Circular or Square

|

|

|

|

|

|

|

|

|

||||||||

|

Bottle diameter(mm)

|

Φ50-Φ95

|

|

|

|

|

|

|

|

|

||||||||

|

Washing

|

Aseptic Water

|

|

|

|

|

|

|

|

|

||||||||

|

Total power

|

2.5

|

3

|

3.5

|

4

|

5.5

|

7.5

|

11

|

15

|

20

|

||||||||

|

Weight (kg)

|

1800

|

2200

|

2800

|

3000

|

4500

|

6000 |

9000 |

15000

|

18000

|

||||||||

|

Overall dimensions(mm)

|

1800*1200

|

2050*1550

|

2400*1750

|

2550*1850

|

3000*2150

|

4200*2700

|

4700*3200

|

6500*3350

|

7200*3650

|

||||||||

Details Images

1)304/316 Stainless steel high precision filling nozzle2) Filling volume adjustable in fine rank, same liquid level after filling

3)All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4) 304/316 stainless steel filling pump

5)Efficient spray nozzle rinse thoroughly and save water for flushing

3)All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4) 304/316 stainless steel filling pump

5)Efficient spray nozzle rinse thoroughly and save water for flushing

1) Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during

capping

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2%

capping

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2%

Related Equipments

Water Treatment System

1. Pure water - RO Reverse osmosis treatment

2. Mineral water - Hollow filter water treatment

2. Mineral water - Hollow filter water treatment

Full automatic bottle blowing machine

Suitable Bottle Volume

1 - Plastic Bottle 0.1 - 3L

2 - Hot Filling Bottle 0.3 - 2.5L

3 - Gallon 2.5 - 5 Gallon

4 - Oil Bottle 0.1 - 6L

5 - PP Bottle 0.3 - 2.5L

1 - Plastic Bottle 0.1 - 3L

2 - Hot Filling Bottle 0.3 - 2.5L

3 - Gallon 2.5 - 5 Gallon

4 - Oil Bottle 0.1 - 6L

5 - PP Bottle 0.3 - 2.5L

Semi-automatic bottle blowing machine

Suitable Bottle Volume

1 - Plastic Bottle 0.1 - 3L

2 - Hot Filling Bottle 0.3 - 2.5L

3 - Gallon 2.5 - 5 Gallon

4 - Oil Bottle 0.1 - 6L

5 - PP Bottle 0.3 - 2.5L

1 - Plastic Bottle 0.1 - 3L

2 - Hot Filling Bottle 0.3 - 2.5L

3 - Gallon 2.5 - 5 Gallon

4 - Oil Bottle 0.1 - 6L

5 - PP Bottle 0.3 - 2.5L

Packing & Delivery

Hot Searches