- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

CNMI

-

Model Number:

-

TC110

-

Type:

-

Epoxy Resin AB Glue, Liquid

-

Product name:

-

Epoxy Resin Crafts Adhesive

-

Color:

-

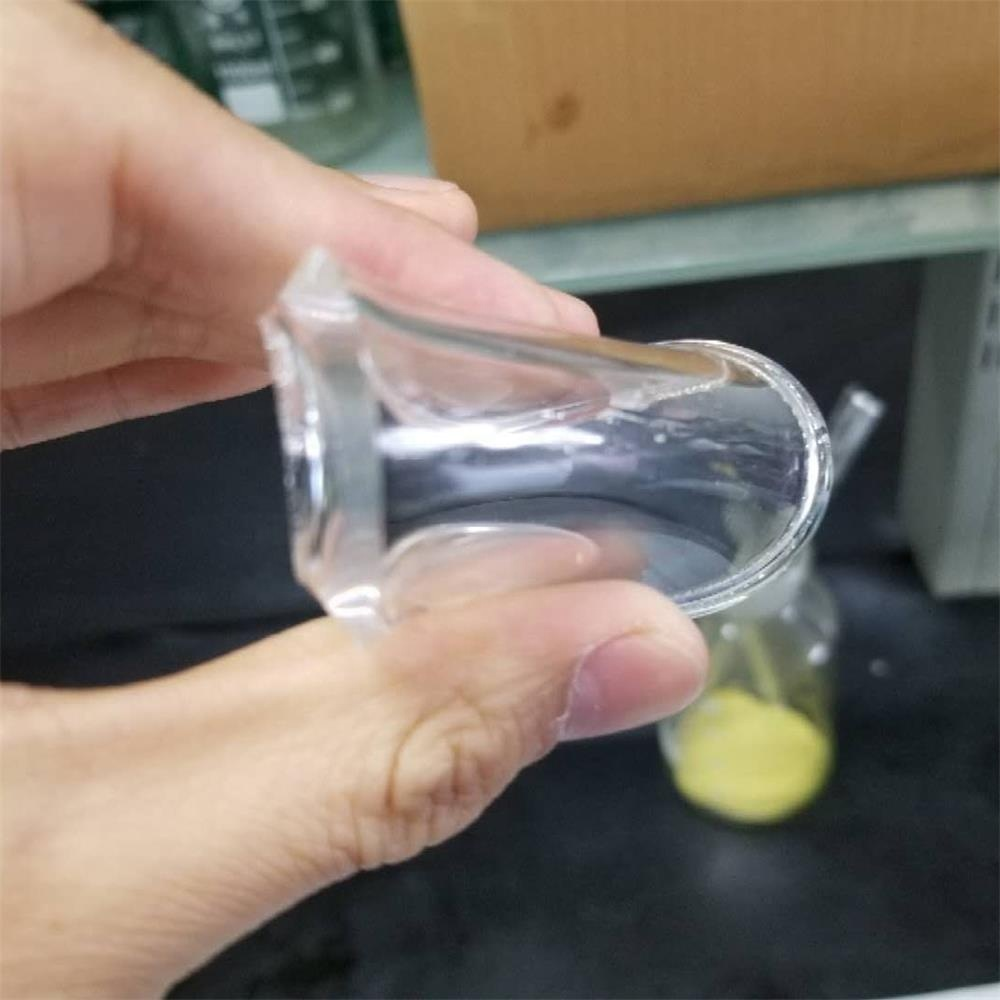

Clear Crystal Colorless

-

Mix Ratio:

-

1:1

-

Application:

-

Woodworking

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

-

Shelf life:

-

12 Months

-

OEM:

-

Accept

-

Usages:

-

Handicrafts

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Epoxy Resin Crafts Adhesive

-

MF:

-

C6H7NO2

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

CNMI

-

Model Number:

-

TC110

-

Type:

-

Epoxy Resin AB Glue, Liquid

-

Product name:

-

Epoxy Resin Crafts Adhesive

-

Color:

-

Clear Crystal Colorless

-

Mix Ratio:

-

1:1

-

Application:

-

Woodworking

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

-

Shelf life:

-

12 Months

-

OEM:

-

Accept

-

Usages:

-

Handicrafts

Product Description

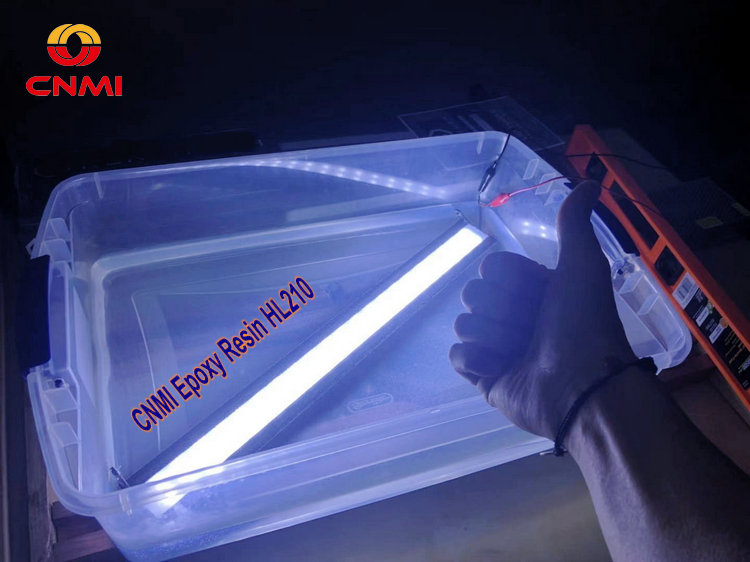

Epoxy Resin Crafts Fast Dry Yellow Resistant No Bubbles Epoxy Resin Crafts Adhesive

Crystal Clear, Strong Formula, Food Safe, Won't Turn Yellow, Non-Toxic, No BPA, Odorless, No VOC, No Bubble, UV Resistance, Scratch Resistance

TC110 Resin for Table Top, Coaster and Trays etc.

TC110 Resin Ratio 1:1 by Volue, Pour Thickness : 1-2cm. Crystal Clear and UV Resistant.

HL310 Resin Used for making River Table.

HL 310 Resin Ratio 3:1 by Weight, Pour Thickness : 3-15cm. Crystal Clear and No Bubbles.

FL210 Resin Used for 3D Floor and Celling, Luxury Coating.

FL210 Resin Ratio 2:1 by Weight, Pour Thickness : 1-2mm one time by one time. Crystal Clear and Scratch Resistant.

Specification

|

Product Name

|

CNMI Epoxy Resin Kit TC110 Epoxy Resin AB Glue for Wood Table Top Coating VOC Free UV Protection

|

|

|

Component

|

Epoxy Resin & Hardener

|

|

|

Customize

|

Accepted

|

|

|

Mixing Viscosity

|

TC110: 2000-3000 Mpa.s ( 25℃ )

FL210: 1000-1500 mpa.s ( 25℃ )

HL310: 300-500 Mpa.s ( 25℃ ) |

|

|

Curing Time

|

TC110/HL310: FL210:

5-7 Hours ( 25℃ ) 12-48 Hours( 25℃ )

2-4 Hours ( 60℃ ) 2-4 Hours ( 60℃ )

|

|

|

Application

|

Top Coating, Floor, River Table, Furniture, Table Top, Bar Top, Counter Top, Tumbler, Coasters and Trays, Photo Frame, Geode Coating, Lamp Potting, Art Painting, Art Work, Art Craft, Jewelry, Guitar Surface, Handicraft, Ashtray, Engraving, Earring, Bracelent, Hair clip, Glass, Figurine, Acrylic Pour Art, Ceiling, Home Depot, Garage, Concrete Floor, Epoxy Floor

|

|

|

Mixing Ratio

|

TC110: 1:1 Mixing By Volume

FL210: 2:1 Mixing By Weight

HL310: 3:1 Mixing By Weight

|

|

|

Feature

|

Crystal Clear, Strong Formula, Food Safe, Not Change to Yellow, Non-Toxic, No BPA, Odorless, No VOC, No Bubble, UV Resistance,

Scratch Resistance, Food Touch, Water Proof, Wear Proof, Electrical Protection, Anti-slip, Heat Insulation, Fireproof, Antiflaming |

|

|

Packing

|

For OEM order, we have 16oz, 32oz, 64oz, 1gallon kit, 2 gallon kit, 5kg drum.

For bulk order, we have 25kg/drum, 200kg/drum, 1150kg/tote ( IBC Drum). |

|

|

Delivery Time

|

3-5 Working days

|

|

|

Certificate

|

ASTM D4236, EN71, SVHC 209-REACN

|

|

|

Note: Typical performance should not be considered as product specifications.

|

|

|

Storage and Shelf Life:

1. Epoxy resin at 25 ℃ to 35℃ , dry and original sealed packaging storage conditions, epoxy resin chemistry. The shelf life of the property is at least 12 months.

2. Epoxy Resin-A and Hardener-B curing agent should be placed in the original packaging, placed in a dry and cool place, avoid direct sunlight, the temperature should not be higher than 25℃. Its chemical properties can be kept for at least 6 months.

Notes:

1. Keep resin surface clean, remove dust , when there is oil , remove with alcohol or acetone.

2. Please mix A/B strictly accord to mix ratio by one direction. Mix thoroughly, adjust the resin quantity according to the

temperature and operation speed, the higher quantity, higher temperature, pot life will be shorter; the less quantity, lower

temperature, pot life will be longer, please adjust resin quantity according to specific condition.

3.Please seal the bung after use, avoid quality change because of humidity air invade in. Please use up all the mixed resin, do not pull the mixed resin back to the A or B resin again.

4. The excess resin can be removed by alcohol or acetone before it is totally cured.

5. Please contact me if you have any problem .

1. Epoxy resin at 25 ℃ to 35℃ , dry and original sealed packaging storage conditions, epoxy resin chemistry. The shelf life of the property is at least 12 months.

2. Epoxy Resin-A and Hardener-B curing agent should be placed in the original packaging, placed in a dry and cool place, avoid direct sunlight, the temperature should not be higher than 25℃. Its chemical properties can be kept for at least 6 months.

Notes:

1. Keep resin surface clean, remove dust , when there is oil , remove with alcohol or acetone.

2. Please mix A/B strictly accord to mix ratio by one direction. Mix thoroughly, adjust the resin quantity according to the

temperature and operation speed, the higher quantity, higher temperature, pot life will be shorter; the less quantity, lower

temperature, pot life will be longer, please adjust resin quantity according to specific condition.

3.Please seal the bung after use, avoid quality change because of humidity air invade in. Please use up all the mixed resin, do not pull the mixed resin back to the A or B resin again.

4. The excess resin can be removed by alcohol or acetone before it is totally cured.

5. Please contact me if you have any problem .

Packing & Delivery

We accept OEM packing, you can choose your personal label, box.

We have 8oz,16oz,1kg,5kg,25kg,25kg,220kg,1150kg drum.

We have bottle ,barrel, IBC Tote .

Why Choose Us

Contact Us

FAQ

Q: Could you supply the

Epoxy Resin AB Glue

samples for we test ?

A: Yes, no problem, pls contact us with our workable for samples.

Q: What’s the best way to mix this Epoxy Resin AB Glue ?

A: Yes, no problem, pls contact us with our workable for samples.

Q: What’s the best way to mix this Epoxy Resin AB Glue ?

A: You’ll want to make sure that you have 1 parts base resin and 1 part curing agent measured precisely, by volume. Pour each into your mixing bucket, and we recommend using a paddle mixer to mix for at least 6-8 minutes or until it is fully mixed. Don’t worry about any bubbles in the mixture, they will all work themselves out.

Q: How long does it take to cure, and what temperatures can I pour the Epoxy Resin AB Glue in ?

A: Our optimum environment temperature range is 25° - 100°C (in a clean, temperature controlled environment. In that temperature range, it will begin to gel in 90-120 minutes, and cure rock hard within 5-7 hours.Temperatures under 25°C will slow the curing process even more. Above 85°C, it will begin to accelerate curing. By the way, we also have high temperature epoxy resin, it can be used on 280°C environment. If you need to use the epoxy resin AB glue at less than 10°C, we recommend that you use our HL210.

Q: Can I use this Epoxy Resin AB Glue on furniture meant for the outdoors ?

A: While our epoxy yellow less over a longer period of time vs all other epoxies, in direct outdoor sunlight, any epoxy will

yellow much faster. It is left to the discretion of the user, but it should be fine in highly shaded areas that are kept from

direct sunlight.

Q: How do I fix an Epoxy Resin AB Glue surface that cured with a streaky finish ?

Q: How long does it take to cure, and what temperatures can I pour the Epoxy Resin AB Glue in ?

A: Our optimum environment temperature range is 25° - 100°C (in a clean, temperature controlled environment. In that temperature range, it will begin to gel in 90-120 minutes, and cure rock hard within 5-7 hours.Temperatures under 25°C will slow the curing process even more. Above 85°C, it will begin to accelerate curing. By the way, we also have high temperature epoxy resin, it can be used on 280°C environment. If you need to use the epoxy resin AB glue at less than 10°C, we recommend that you use our HL210.

Q: Can I use this Epoxy Resin AB Glue on furniture meant for the outdoors ?

A: While our epoxy yellow less over a longer period of time vs all other epoxies, in direct outdoor sunlight, any epoxy will

yellow much faster. It is left to the discretion of the user, but it should be fine in highly shaded areas that are kept from

direct sunlight.

Q: How do I fix an Epoxy Resin AB Glue surface that cured with a streaky finish ?

A: There are a few factors that can lead to a streaky finish on the surface of cured epoxy. Under most circumstances, a thin flood coat of epoxy can fix this if the streaks

are due to a surface texture. If the streaks are visible, with varying appearance, you may need to sand or grind away the streaky epoxy material, and reapply a flood coat to give a better finish. For instances where there is a swirly surface texture from contaminants or poorly mixed epoxy, the surface should be sanded prior to applying a flood coat of epoxy.

Q: How much mica or pigment can I use to the Epoxy Resin AB Glue ?

A: We suggest only using epoxy resin color pigments (like our Supercolor Liquid Pigments), mica pigment powder, alcohol inks and dyes. With that said, 12% is the limit of color that can be added before the curing process is affected. Remember, the higher percent of color you add, the less chance of a perfect cure. If you go too high, your project will not cure. Our limit for Liquid Glass is 12%, which is more than enough to create an opaque finish, but also allows for a smaller percent to achieve a translucent finish.

are due to a surface texture. If the streaks are visible, with varying appearance, you may need to sand or grind away the streaky epoxy material, and reapply a flood coat to give a better finish. For instances where there is a swirly surface texture from contaminants or poorly mixed epoxy, the surface should be sanded prior to applying a flood coat of epoxy.

Q: How much mica or pigment can I use to the Epoxy Resin AB Glue ?

A: We suggest only using epoxy resin color pigments (like our Supercolor Liquid Pigments), mica pigment powder, alcohol inks and dyes. With that said, 12% is the limit of color that can be added before the curing process is affected. Remember, the higher percent of color you add, the less chance of a perfect cure. If you go too high, your project will not cure. Our limit for Liquid Glass is 12%, which is more than enough to create an opaque finish, but also allows for a smaller percent to achieve a translucent finish.

Hot Searches