- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SMAC

-

Year:

-

latest date

-

Power (kW):

-

2.2

-

Weight (KG):

-

1000

-

Marketing Type:

-

New Product 2022

-

Min. bending radius:

-

R≥1.5Dmm

-

Max. Bending radius(Standard):

-

100mm

-

Though Effective Distance:

-

1800mm

-

Head overhang:

-

450mm

-

Head height:

-

75mm

-

Bending center height:

-

900mm

-

Max. Bending Speed:

-

180°/sec

-

Pipes storage capacity:

-

1000pieces

-

Max rotating speed:

-

360°/sec

Quick Details

-

Bending Radius (mm):

-

1.03 - 100

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

±0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SMAC

-

Year:

-

latest date

-

Power (kW):

-

2.2

-

Weight (KG):

-

1000

-

Marketing Type:

-

New Product 2022

-

Min. bending radius:

-

R≥1.5Dmm

-

Max. Bending radius(Standard):

-

100mm

-

Though Effective Distance:

-

1800mm

-

Head overhang:

-

450mm

-

Head height:

-

75mm

-

Bending center height:

-

900mm

-

Max. Bending Speed:

-

180°/sec

-

Pipes storage capacity:

-

1000pieces

-

Max rotating speed:

-

360°/sec

Recommend Products

Products Description

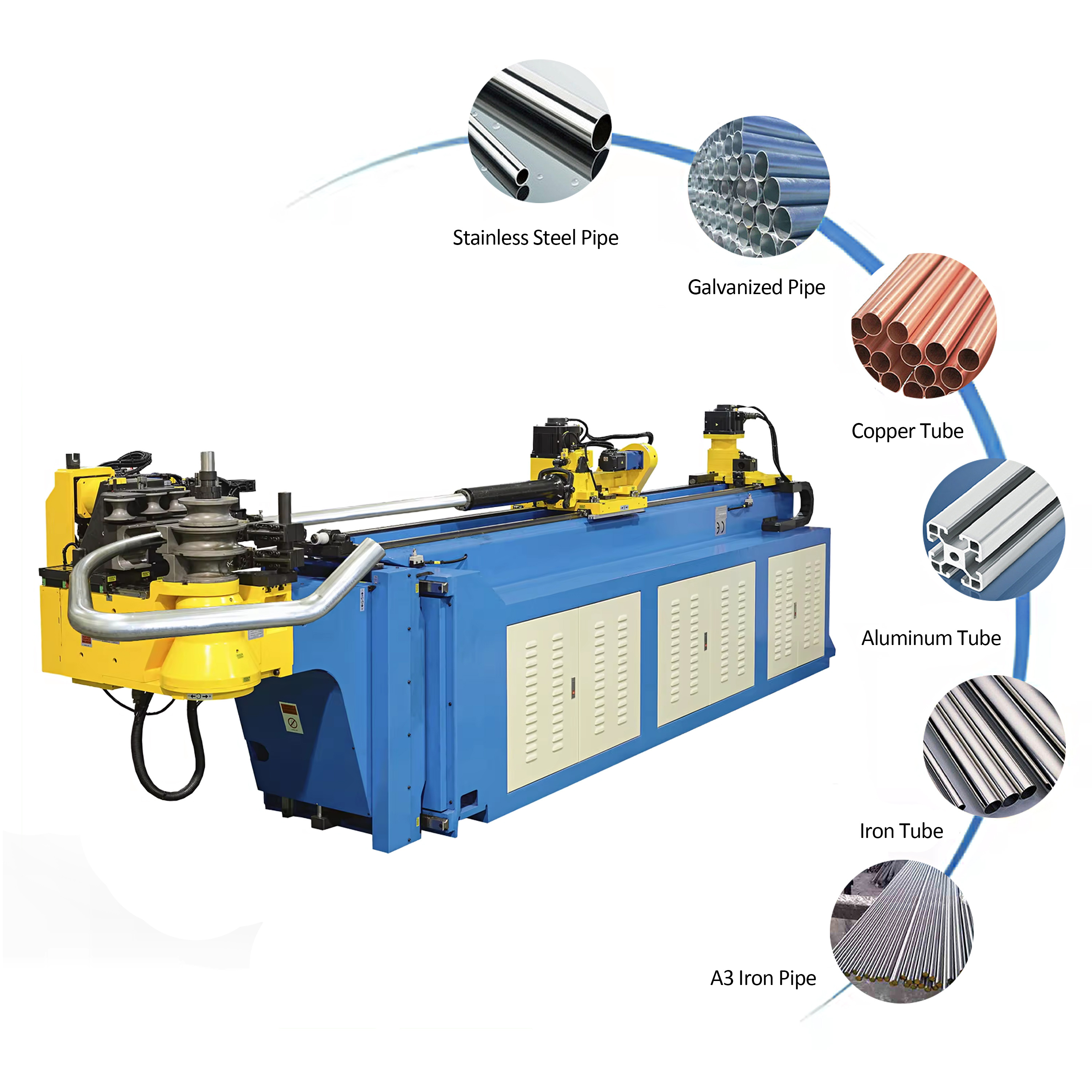

Introuduction

This machine is servo drove and its electronic control system adopts touch screen and PLC. It is equipped with devices of pipe clamping, guide mould, mandrel, crease-resistant, assist pushing, pipe bending ,rotating pipe and so on. Under cooling condition, this professional, high speed European pipe bending machine can bend various dimension both normal and abnormal shape metal pipes and bending angles are controlled by high precision imported servo motor which ensures high precision of this machine.

Characteristics

⭐The pipe bender adopts

touch screen and numerical control module

, dialogue operation, easy program setting

⭐

The bed structure is stable and not easy to deform.

⭐

Each file can be set with

16 elbow angles

, and the memory can store 16 groups of files.

⭐

With the function of slow positioning, the bending angle is stable and the repetition accuracy is

± 0.1 °

Main Features

The frame is assembled in monoblock after welding, it is processed by heating treatment, machining by CNC Floor Boring and Milling center, ensuring the rigidity and processing accuracy of the frame.

⭐

The error message is displayed on the screen to help the operator eliminate it immediately.

⭐

Provide

the processing value of the coordinate conversion elbow developed by ourselves

. The software can be purchased and installed on the desktop for editing and calculation.

Specifcation

|

No

|

Name

|

|

Unit

|

Parameter

|

||

|

03

|

Min. bending radius

|

|

mm

|

R≥1.5D

|

||

|

04

|

Max. Bending radius(Standard)

|

|

mm

|

100

|

||

|

05

|

Though Effective Distance

|

|

mm

|

1800

|

||

|

06

|

Head overhang (on bending center)

|

|

mm

|

450

|

||

|

07

|

Head height (on bending center)

|

|

mm

|

75

|

||

|

08

|

Bending center height (from floor)

|

|

mm

|

900

|

||

|

09

|

Max. Bending Angle

|

|

°

|

190°

|

||

|

10

|

Max. Bending Speed

|

|

°/sec

|

180

|

||

|

11

|

Bending Angle Precision

|

|

°

|

±0.1

|

||

|

12

|

Feeding Precision

|

|

mm

|

±0.1

|

||

|

13

|

Rotating-tube Precision

|

|

°

|

±0.1

|

||

|

14

|

Pipes storage capacity

|

|

pieces

|

1000

|

||

|

15

|

Max rotating speed

|

|

°/sec

|

360

|

||

|

16

|

Hydraulic System Motor Power

|

|

KW

|

2.2

|

||

|

17

|

Hydraulic Pump Output Volume

|

|

L

|

12

|

||

|

18

|

Max Pressure

|

|

Mpa

|

16

|

||

|

19

|

Oil Tank Volume

|

|

L

|

100

|

||

|

20

|

Repeated Location

Precision |

Bending Axis

|

°

|

±0.1

|

||

|

21

|

|

Diversion Axis

|

°

|

±0.1

|

||

|

22

|

Ovality rate after processed

|

|

<8%

|

|

||

|

23

|

Thickness Reduction after processed

|

|

<12%

|

|

||

|

|

Tooling Center Height

|

|

mm

|

22

|

||

|

24

|

Feeding Method

|

|

1.clamping

|

2.loosen

|

||

|

25

|

Feeding Servo

|

|

KW

|

0.4

|

||

|

26

|

Rotating Servo

|

|

KW

|

0.4

|

||

|

27

|

Bending Servo

|

|

KW

|

1.0

|

||

|

28

|

Gross Power

|

|

KW

|

5

|

||

|

29

|

Machine Voltage

|

|

V

|

As per customer’s requirements

|

||

|

30

|

L*W*H

|

|

mm

|

3000*700*1300

|

||

Hot Searches