- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HeZhi

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

1300*530*1200

-

Power (kW):

-

30kw

-

Weight (KG):

-

900 KG

-

Name:

-

Pellet mill

-

Raw material:

-

Wood Chips

-

Pellet size:

-

6/8/10/12mm Customized

-

Function:

-

Make Wod Pellet

-

Usage:

-

Make Making Biomass Fuel

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

Quick Details

-

Pellet Diameter (mm):

-

1 - 22

-

Output (kg/h):

-

100 - 2000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HeZhi

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

1300*530*1200

-

Power (kW):

-

30kw

-

Weight (KG):

-

900 KG

-

Name:

-

Pellet mill

-

Raw material:

-

Wood Chips

-

Pellet size:

-

6/8/10/12mm Customized

-

Function:

-

Make Wod Pellet

-

Usage:

-

Make Making Biomass Fuel

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

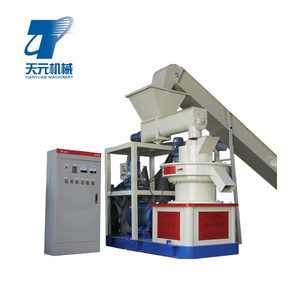

Biomass Pellet Mill

Features of the model:

1. Adopt the pressure wheel, and both ends and the inner and outer ring of the die plate have the same line speed, so there is no misalignment friction between the wheel and the die, which reduces the resistance, lowers the kinetic energy loss, prolongs the service life of the die, and reduces the production cost.

2. The press wheel is set up evenly, running smoothly, while increasing the pressing area and improving the production efficiency

3. Adopt the center of the screw to adjust the pressure structure, the gap of the mold is as big as small, applicable to different materials, to ensure the pressing effect.

4. This model is equipped with a variety of aperture molds from Φ4-Φ20mm, which can adapt to different materials for granulation and achieve the best benefit.

|

Model

|

Output (kg/h)

|

Power (kw)

|

Speed Reducer

|

Size (mm)

|

Weight (kg)

|

|

250

|

150

|

15

|

KAF87

|

1120*440*1060

|

600

|

|

300

|

200

|

22

|

KAF97

|

1280*550*1200

|

800

|

|

350

|

300

|

30

|

KAF107

|

1300*530*1200

|

900

|

|

400

|

500-600

|

37

|

KAF107

|

1380*530*1200

|

1200

|

|

450

|

600-800

|

45

|

KAF127

|

1620*690*1600

|

1500

|

|

550

|

800-1000

|

55

|

KAF127

|

1700*690*1600

|

1600

|

|

650

|

1000-1200

|

75

|

Vertical

|

1800*720*1650

|

1700

|

|

750

|

1200-1400

|

90

|

Vertical

|

1850*730*1700

|

1800

|

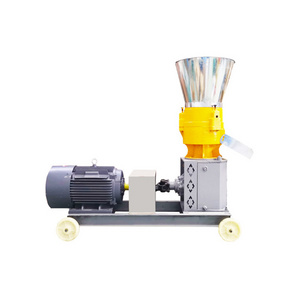

The raw materials of this machine can be crushed wastes such as peanut shells, sawdust, grass, straw, wood chips, etc., which can be pressed into various biomass fuels.It is often called wood pellet mill,wood pellet machine,machine to make pellets homemade.

1. Compression roll and flat die is composed of alloyed durable material, so it has superiority of long life, compact structure.

2. Our machine adopts robust steel materials and high quality copper electric motor.

2. Our machine adopts robust steel materials and high quality copper electric motor.

3. The produced fuel particles are high thermal energy and storage resistance, so they are environmentally friendly and efficientfuel. It features a granulating uniform, stable performance and a long service life.

Scope of application:

Mainly suitable for coarse fiber granulation, such as: wood chips, rice husk, cotton stalks, cotton seed bark, weeds and other kinds of crop straw and factory waste, low adhesion rate, difficult to shape the material granulation, but also for biological fertilizer, organic fertilizer, compound fertilizer and other low-temperature granulation. Dry in and dry out, without drying (raw material moisture is not less than 10% of the national export volume moisture standard). Adopt differential speed, with electric motor or diesel engine. Low energy consumption, high output, easy to operate.

1. Adopting the new technology of extrusion granulation and polishing, it has completely solved the key technical problems such as low addition of organic raw materials (about 30%), difficult granulation, and raw materials need to be dried and crushed. SKJ-200 type, using three times extrusion, increasing the pressure wheel in the pressing area, reducing friction, reducing energy consumption, low energy consumption and high output.

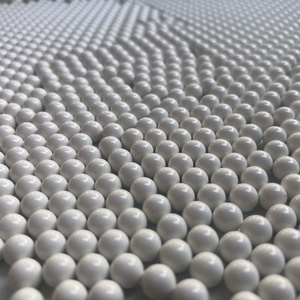

2. It can produce round ball type pure organic fertilizer, organic inorganic fertilizer and bio-organic fertilizer; the granules are uniform, smooth and round, with high strength and good fluidity.

3. The unique three-in-one machine is used to complete the whole process of low-temperature drying, cooling and sieving at one time, with low investment in equipment and low running cost. The viability of microbial bacteria is >90%.

4. Widely used in livestock breeding industry, large and small breeding plants, feed factories and brewing, sugar, paper, medicine, tobacco factories and other industries of organic waste re-granulation, is the ideal equipment of choice for (bio) organic fertilizer production enterprises.

The raw materials of the pellets come from a wide range of sources, including sawdust, shavings, bark, sanding powder, waste wood, branches and trees produced in wood processing and artificial board production; various types of straw produced after crop harvesting; other types of combustible biomass as raw materials, without adding any adhesive, and through equipment processing, all of which can be used to make biomass pellet fuel.

1. The pellet fuel after forming has a large specific gravity, small volume, and is resistant to burning

2,Save energy and reduce emissions, efficient and clean renewable energy

3,Particle density is more than 1100kg/m3, which is very convenient for conveying and storage.

4. Widely used in heating, living stoves, boilers, industrial boilers, power plants

Wood Working China

located in Qingdao West Coast Economic New Zone. The great success required constant expansion, WoodworkingChina was acquired by HEZHI Group in 2015 of the strategic vision of expanding market scope.

We has convenient transportation and strong production strength. WWC is a high-tech industrialized entity integrating

Saw machine, Press Machine, Edge banding machine, Sanding Machine, Drilling Machine, Polishing Machine, Woodworking Planer, Vacuum Laminating Machine,

Pellet Machine,

Spray paint machine and CNC Router Machine, development, production,

operation, export and service.

We owned 3600m2 work shop area for production with 2x10 cranes.Another 2600m2 space is planned for extension.

ISO9001 and CE

certificate is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3DSolidworks

is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer, our staff and our company.

Choose Hezhi,Get factory price and reliable Woodworking Machinery!

1. What is your company positioning?

HEZHI MACHINERY, dedicated to precision equipment manufacturing. Intelligent manufacturing, innovation sharing.

2. How do you do quality control?

HEZHI MACHINERY develops and implements strict quality management internal control standards to achieve close monitoring of the entire machine tool design and manufacturing process. 45 inspection and testing items, 632 quality

control points, 48-hour high-speed full-stroke load processing test. Germany's ZEISS three-coordinate-measuring instrument, Britain's RENISHAW laser interferometer and other world-quality precision testing equipment are used to ensure the precise control of machine tool details.

control points, 48-hour high-speed full-stroke load processing test. Germany's ZEISS three-coordinate-measuring instrument, Britain's RENISHAW laser interferometer and other world-quality precision testing equipment are used to ensure the precise control of machine tool details.

3. What is your market advantage?

We provide not only machine tools, but one-stop solutions for machine tools.

4. Do you have after-sales service, and how to do it?

The whole machine is guaranteed for 1 years, and the service is responded immediately. we will actively and promptly solve problems for users as appropriate, and provide technical service support through telephone and video. If necessary, they will go to the customer site for on-site service.

5.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can

protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the

products(as you stated in the purchase order).If the supplier finds breach of these contractual obligations, alibaba will

indemnify you for 100% of your trade guarantee. Therefore, I believe that through trade guarantees, you will have greater

confidence to cooperate with us. it can guarantee your interests.

protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the

products(as you stated in the purchase order).If the supplier finds breach of these contractual obligations, alibaba will

indemnify you for 100% of your trade guarantee. Therefore, I believe that through trade guarantees, you will have greater

confidence to cooperate with us. it can guarantee your interests.

6.Do your products support trade assurance?

Yes, our products are all supported.

Hot Searches