- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

0.43kw

-

Dimension(L*W*H):

-

2200*720*1200mm

-

Weight:

-

250 KG

-

Name:

-

High quality spring roll skin making machine

-

Function:

-

Spring Roll Pastry

-

Final product:

-

spring roll skin

-

Material:

-

Stainess Steel

-

Feature:

-

automatic

-

Capacity:

-

400-1000pcs/h

-

Shape:

-

Round Square Rectangle

-

Processing Types:

-

Grain Procesing Machine

-

Power Source:

-

gas

-

After-sales Service Provided:

-

on-line service

Quick Details

-

Production Capacity:

-

400-1000pcs/h

-

Place of Origin:

-

HEN

-

Brand Name:

-

QUATE

-

Voltage:

-

220V

-

Power:

-

0.43kw

-

Dimension(L*W*H):

-

2200*720*1200mm

-

Weight:

-

250 KG

-

Name:

-

High quality spring roll skin making machine

-

Function:

-

Spring Roll Pastry

-

Final product:

-

spring roll skin

-

Material:

-

Stainess Steel

-

Feature:

-

automatic

-

Capacity:

-

400-1000pcs/h

-

Shape:

-

Round Square Rectangle

-

Processing Types:

-

Grain Procesing Machine

-

Power Source:

-

gas

-

After-sales Service Provided:

-

on-line service

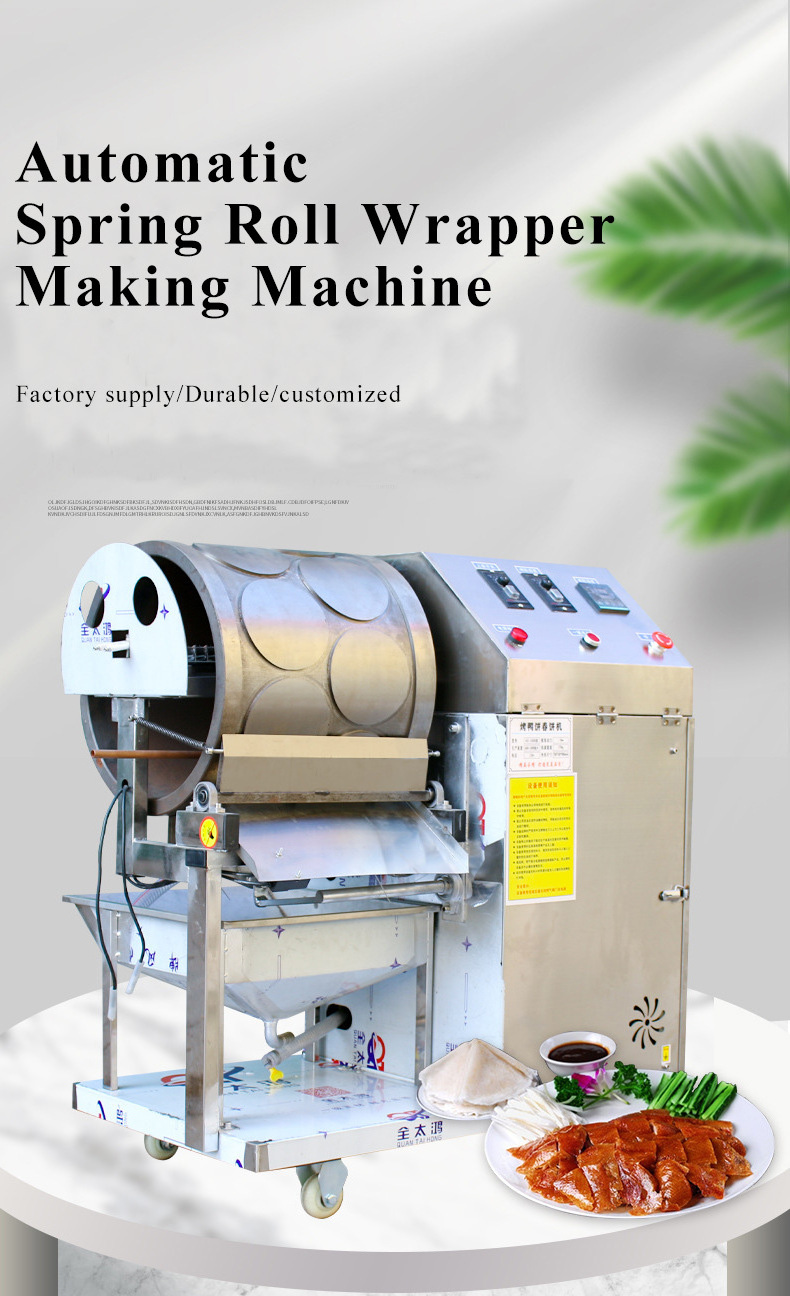

Product Overview

High Effiency Stainless Steel Spring Roll Dumpling Skin Wrapper Machine

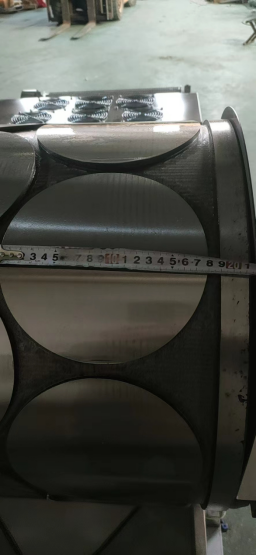

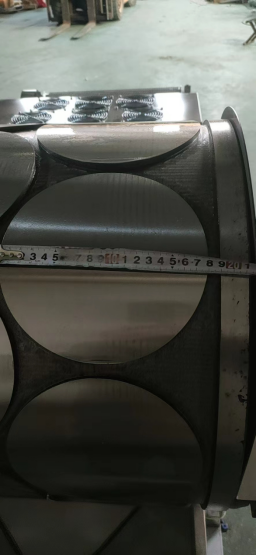

Principle:

The noodle paste is prepared according to the requirements of the noodle paste production process. After the noodle paste is heated and baked by a round baking wheel,it becomes a spring roll skin or other flaky food with a fixed thickness.

Process:

Put the prepared batter into the batter bucket, when the roasting wheel is heated to 150°C;start the batter pump to send the batter to the nozzle, and operate the clutch lever to make the batter adhere to the arc of the roasting wheel On the surface, when the baking wheel rotates through an angle of 270-300 degrees, the batter is matured and automatically separated from the baking wheel to form a spring roll skin with a fixed thickness. After being cut into squares by a cutting machine, it can be folded and sold, or wrapped immediately.

FEATURES AT A GLANCE

1.This production line may manufacture

thickness 0.3-2.0 mm

spring roll skin, the curry cutie, the egg skin and the crepes, and may manufacture other laminated , food, suits in the food products factory , the hotel , the fast food restaurant and so on.

2.The Stainless Steel Spring Roll Sheet Production Line is made of

Stainless Steel;

it uses flour as material, you also can add some spice to make spring roll sheet.

Operation is very easy and has high capacity! It can make

round or rectangular (need Cutting Part) spring roll sheet.

PRODUCT SPECIFICATIONS

|

Model

|

QTSP-1

|

|

|

Power source

|

Gas hated(can choose electric heating)

|

|

|

Capital(for single row)

|

400-1000pcs/h(depends on the size of the spring roll wrapper)

|

|

|

2 row and 3 row can be costomized

|

2 row and 3 row can be customized

|

|

|

Gas consumption

|

0.6kg gas per hour of liquefied petroleum gas

|

|

|

Power consumption

|

0.43kw

|

|

|

Shape

|

round and square or customized

|

|

|

Conveyor belt length

|

1.2m

|

|

|

Main machine size

|

900*720*1200mm

|

|

|

Conveyor belt size

|

1300*530*400mm

|

|

|

Weight

|

250kg

|

|

Hot Searches