- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

300-1000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qixin

-

Voltage:

-

380v/220v

-

Dimension(L*W*H):

-

1900*780*1200mm

-

Weight:

-

280 KG

-

Name:

-

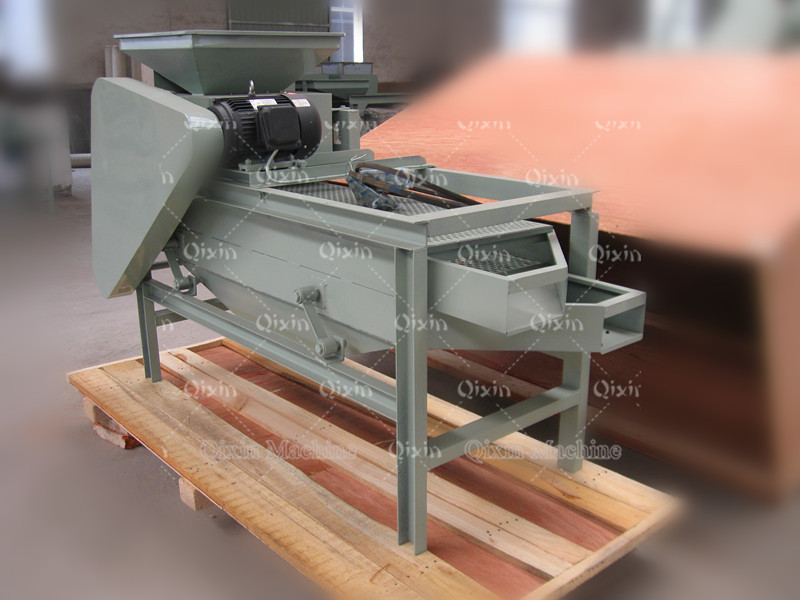

nut shelling cracking machine

-

Application:

-

almond palm nut hazelnut peach pit ou li guo etc

-

Function:

-

for breaking outer shell of nuts

-

Capacity:

-

300-1000kg/h

-

Shelling rate:

-

95~99%

-

Color:

-

Silver

-

Related machine:

-

Shell Seperator

-

Advantage:

-

High Effiency Low Cost

-

Packing:

-

Plywood Carton

-

MOQ:

-

1 Set

Quick Details

-

Marketing Type:

-

New Product 2021

-

Type:

-

almond nut palm nut shelling machine

-

Use:

-

nut sheller

-

Production Capacity:

-

300-1000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qixin

-

Voltage:

-

380v/220v

-

Dimension(L*W*H):

-

1900*780*1200mm

-

Weight:

-

280 KG

-

Name:

-

nut shelling cracking machine

-

Application:

-

almond palm nut hazelnut peach pit ou li guo etc

-

Function:

-

for breaking outer shell of nuts

-

Capacity:

-

300-1000kg/h

-

Shelling rate:

-

95~99%

-

Color:

-

Silver

-

Related machine:

-

Shell Seperator

-

Advantage:

-

High Effiency Low Cost

-

Packing:

-

Plywood Carton

-

MOQ:

-

1 Set

Favored at home and abroad almond sheller palm kernel shell separator palm kernel nut cracker machine

Brief introduction of the Favored at home and abroad almond sheller palm kernel shell separator palm kernel nut cracker:

Application: This Favored at home and abroad almond sheller palm kernel shell separator palm kernel nut cracker is for breaking the hard outer shell of nuts, such as almond nut, palm nut, hazelnut, peach pit, ou li guo, apricot and filbert and so on.

Production suggestion: Small shelling machine: It is a one-level shelling, and the roll gap can be adjusted. Considering the size of nuts is different, generally suggest shell the big size nuts first, then adjust the gap and then shell the smaller ones. Follow this operation and loop in turn …………. The roller gap should be 1-1.5mm smaller than the deflection size of the nuts. (For example, the raw nuts: the large oblate diameter is 15 mm, the middle oblate diameter is 12 mm, and the small oblate diameter is 9 mm. Adjust according to the raw materials: the first roll gap is 14 mm for shelling big nuts. The second roll-off gap is 11 mm for the middle ones, and the third roll-off gap is 8 mm for smaller ones. The gap is small. The above is just for reference. It is better to adjust the gap according to the actual raw materials to ensure that the nuts are not broken.

Feature: The machine is equipped with a chain rotation, vibration material the strut connection between the vibration sieve body and rack with special rubber sleeve, durable shock-absorbing characteristics at the junction. It is easy to operate with wide application, high shelling rate, cost-effective and so on.

Main technical parameter of the Favored at home and abroad almond sheller palm kernel shell separator palm kernel nut cracker:

|

Model |

Capacity |

Power |

Overall Dimension |

Weight |

|

QX-NS400 |

300-500kg/h |

2.2kw |

1900*780*1200 mm |

280kg |

For large production. we have a bigger model shelling machine to meet your demand: It is composed of feeding hopper, elevator, one, two, three - stage shelling roller, the material screen for discharging materials for each grade and the total vibrating screen.The machine uses the chain to turn and shake out the material.

Other related products to process nuts as the auxiliary equipment of nut sheller:

1. Sizing screen machine:

This machine is used to grade almond, hazelnut, macadamia nut etc. into three sizes,big,small and medium or more sizes.

The machine consists of one, two, tertiary vibrating screen doing classification at the same time.

The live screen surface mesh 6 -- 10 mm,.

According to different varieties, replacing sieve to separate the size of the qualified level.

This machine is the most ideal and economical processing equipment for nuts at present. The sieves can be customized two or three layers according to the raw materials and the customers’s demand

|

Model |

Capacity |

Power |

Overall Dimension |

Weight |

|

QX-G400 |

300-500kg/h |

1.1kw |

2400*800*1400 mm |

260kg |

|

QX-G8 00 |

600-8 00 kg/h |

1.1kw |

2 4 0 0* 80 0*16 0 0 mm |

300kg |

2. Shell-kernel separator:

After shelling, the kernels and shells are together. This machine is used for separating the kernels from the shells.

It is of high separating ratio , low crushing ratio, high quality and easy operation.

This machine uses the weight and suspend speed different between the kernel and the shell to separate the kernel from the shell to get the clean kernels.

Depending on capacity and efficiency, the separator can be customized sing-fun type and double-fun type:

| Model | Capacity | Power | Overal size | Weight |

| QX-FL500 | 400-600kg/h | 3kw | 2300*800*1600mm | 200kg |

| QX-FL800 | 600-800kg/h | 4kw | 3300*900*1670mm | 380kg |

We can match production line for you: