- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Singel phase 220V

-

Current:

-

37A

-

Rated Capacity:

-

15KW

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

550*220*490mm

-

Use:

-

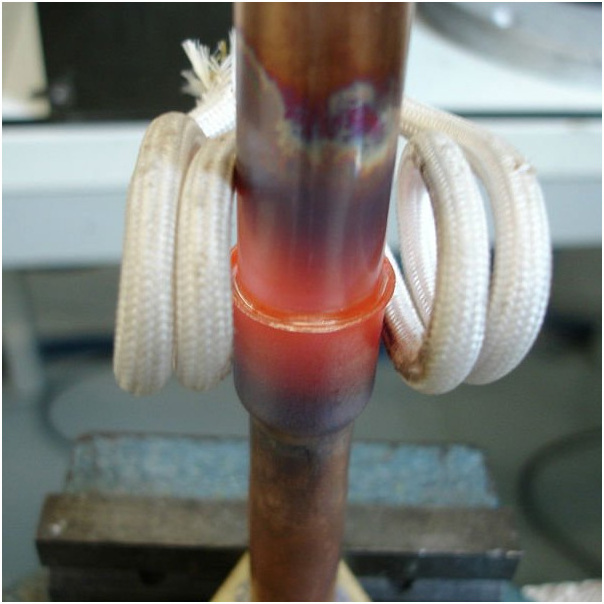

metal brazing & welding

-

Product name:

-

Induction Brazing Equipment Induction Welding Machine

-

Application:

-

Metal heating, brazing, welding, soldering

-

Maximum oscillation power:

-

15KVA

-

Oscillation Frequency:

-

30-100KHZ

-

Work Voltage:

-

single phase 220V 50/60HZ

-

The Range of operating voltage:

-

200V to 240V

-

The Flow Rate of Cooling Water:

-

0.2Mpa 6L/Min

-

Model Number:

-

WXH-15AB

-

Working Theory:

-

Electromagnetic Induction Heating

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Wangxin

-

Weight (KG):

-

35

-

Voltage:

-

Singel phase 220V

-

Current:

-

37A

-

Rated Capacity:

-

15KW

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

550*220*490mm

-

Use:

-

metal brazing & welding

-

Product name:

-

Induction Brazing Equipment Induction Welding Machine

-

Application:

-

Metal heating, brazing, welding, soldering

-

Maximum oscillation power:

-

15KVA

-

Oscillation Frequency:

-

30-100KHZ

-

Work Voltage:

-

single phase 220V 50/60HZ

-

The Range of operating voltage:

-

200V to 240V

-

The Flow Rate of Cooling Water:

-

0.2Mpa 6L/Min

-

Model Number:

-

WXH-15AB

-

Working Theory:

-

Electromagnetic Induction Heating

Induction Brazing Equipment Induction Welding Machine

Knowledge of Induction Brazing

Why induction brazing is better?

1. Speedier Solution

Induction heating transfers more energy per square millimeter than an open flame. Induction can therefor more parts per hour than alternative processes. Rapid and precise heating results in less mass to be heated. And there is less damage to surrounding

insulation.

2. Quicker Throughput

Induction is ideal for in-line integration. Batches of parts no longer have to be taken aside for seperate brazing or sent off

site.

3. Consistent Performance

Induction heating is controllable and repeatable. Enter the desired process parameters and induction equipment will repeat the heating cycles.

4. Unique Controllability

Induction lets operators videw the brazing process, something that is difficult with flames. Such precise heating minimize the risk of oveheating.

5. More productive Environment

Open flame creat uncomfortable working environments. Induction is quiet and clean. It is easy to extract fumes and there is virtually no increase in ambinet temperature.

6. Compact Footprint

Wangxin induction brazing equipment has a small footprint. Induction stations slot easily into production cells and existing layouts.

7. No-contact process

Induction produces heat within the base matals and nowhere else. Unlike flame heating the base metal never comes into contact with the heat source. The homogeneous and controlled heat minimizes distortion, and there is no danger to creat hydrogen embrittlement.

Induction heating transfers more energy per square millimeter than an open flame. Induction can therefor more parts per hour than alternative processes. Rapid and precise heating results in less mass to be heated. And there is less damage to surrounding

insulation.

2. Quicker Throughput

Induction is ideal for in-line integration. Batches of parts no longer have to be taken aside for seperate brazing or sent off

site.

3. Consistent Performance

Induction heating is controllable and repeatable. Enter the desired process parameters and induction equipment will repeat the heating cycles.

4. Unique Controllability

Induction lets operators videw the brazing process, something that is difficult with flames. Such precise heating minimize the risk of oveheating.

5. More productive Environment

Open flame creat uncomfortable working environments. Induction is quiet and clean. It is easy to extract fumes and there is virtually no increase in ambinet temperature.

6. Compact Footprint

Wangxin induction brazing equipment has a small footprint. Induction stations slot easily into production cells and existing layouts.

7. No-contact process

Induction produces heat within the base matals and nowhere else. Unlike flame heating the base metal never comes into contact with the heat source. The homogeneous and controlled heat minimizes distortion, and there is no danger to creat hydrogen embrittlement.

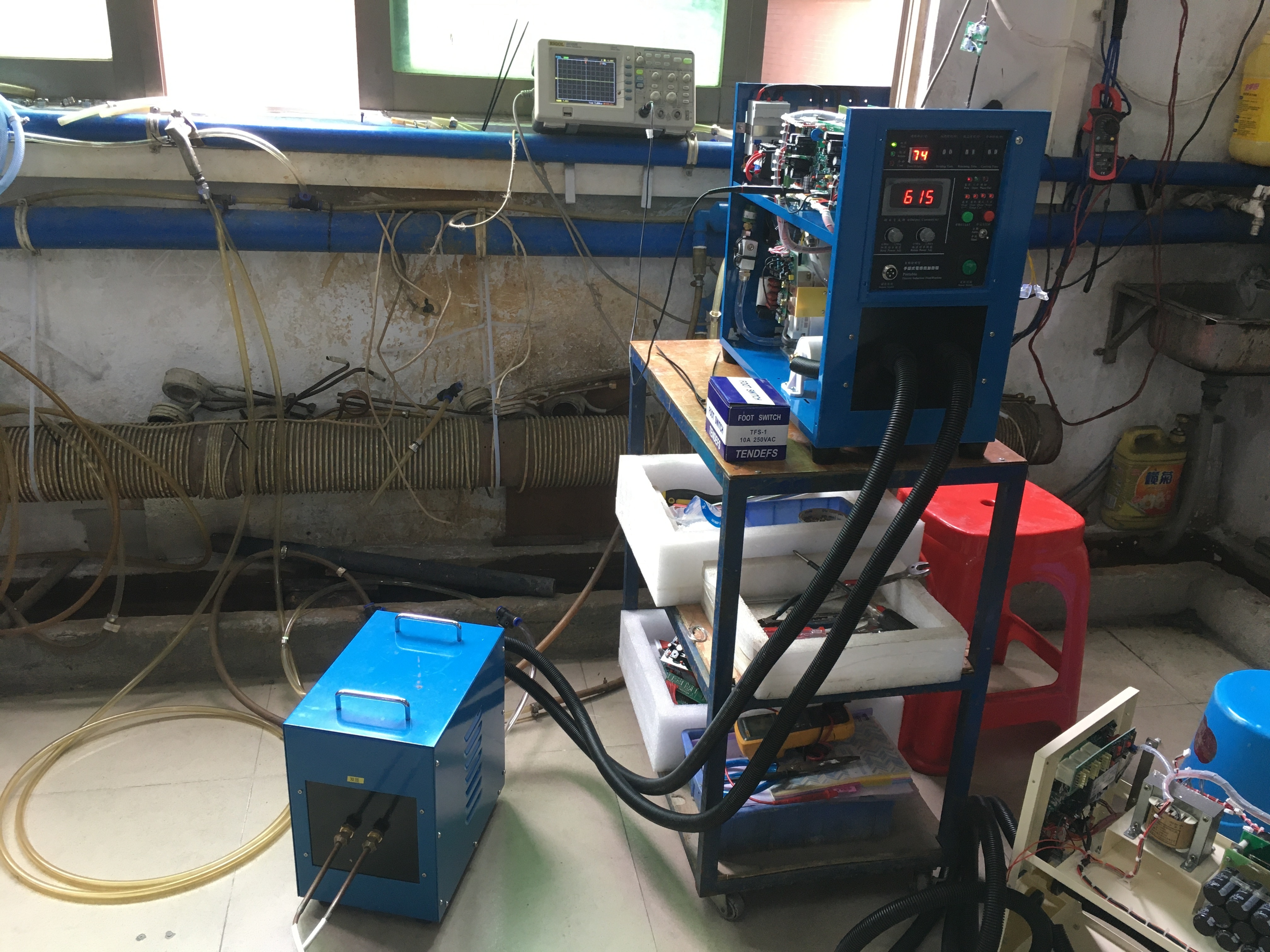

Machine Show

We both have blue color machine and white color machine for option. Choose any one you like!

Technical Parameters

|

Model

|

Input Voltage

|

Frequency

|

Max Input Current

|

Water Flow For Cooling

|

|

WXH-15/15AB

|

Single Phase 220V, 50/60HZ

|

30-100KHZ

|

37A

|

0.2MPa, 6L/Min

|

|

WXH-25/25AB

|

3 Phase 380V, 50/60HZ

|

30-80KHZ

|

28A

|

0.2MPa, 6L/Min

|

|

WXH-30

|

3 Phase 380V, 50/60HZ

|

30-80KHZ

|

38A

|

0.2MPa, 7L/Min

|

|

WXH-40

|

3 Phase 380V, 50/60HZ

|

30-80KHZ

|

45A

|

0.2MPa, 7L/Min

|

|

WXH-60

|

3 Phase 380V, 50/60HZ

|

30-80KHZ

|

75A

|

0.2MPa, 9L/Min

|

|

WXH-80

|

3 Phase 380V, 50/60HZ

|

30-80KHZ

|

105A

|

0.2MPa, 9L/Min

|

Application

Factors Influence Welding Effect

Mind The Gap Between Two Brazing Parts!

Have the correct gap between the base metals is crucial. Tensile and shear strengths depends on having the correct clearance between the base materials.

Too small a gap, the alloy will not spread properly through the joint.

Too large a gap, minimizes capillary force and leads to weak joints and porosity.

Usually the strongest joints are made by allowing just enough space for the filler metal to flow into the joint area. Wider

spacing will generally result in a weaker joint. The optimum space is typically 0.05-0.1mm for material with a high silver content. This gap means at brazing temperature not room temperature.

Too small a gap, the alloy will not spread properly through the joint.

Too large a gap, minimizes capillary force and leads to weak joints and porosity.

Usually the strongest joints are made by allowing just enough space for the filler metal to flow into the joint area. Wider

spacing will generally result in a weaker joint. The optimum space is typically 0.05-0.1mm for material with a high silver content. This gap means at brazing temperature not room temperature.

Recommend Products

High Frequency Series Machine (Frequency 30-100KHZ)

Process Flow

Wangxin is a really manufacturer for more than 15 years, all manufacturing procedure are finished by ourselves, from raw material purchasing to installation, from coils making to machine commissionning. So we can more easily control the quality and production schedule. What's more, we have our own R&D team and strict QA department, which makes us become stronger and stronger in the competitive market. Come on, dear! Wangxin will satisfy you all.

Service

1. One year warranty time and 24 hours online service

2. Within one year free warranty, any fault caused by non-artificial reason, any quality problem like design, manufacture or procedure occurs, Wangxin would provide free replacement parts.

3. Large inventory of spare parts ready for immediate delivery.

4. Customized design and induction heating solutions.

5. Welcome your engineers to come to factory accept maintenance training & trouble shooting guide.

2. Within one year free warranty, any fault caused by non-artificial reason, any quality problem like design, manufacture or procedure occurs, Wangxin would provide free replacement parts.

3. Large inventory of spare parts ready for immediate delivery.

4. Customized design and induction heating solutions.

5. Welcome your engineers to come to factory accept maintenance training & trouble shooting guide.

Hot Searches