- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 50HZ

-

Dimensions:

-

145cm*63cm*47cm

-

Rated Capacity:

-

4500W

-

Weight (KG):

-

130 KG

-

Heating Zone::

-

upper 3 / down 2

-

Soldering Area::

-

300 x 960 mm / 11.8 x 37.8 in.

-

Length of Heating Zone::

-

960 mm / 37.8 in.

-

Max Width of PCB Board::

-

300 mm / 11.8 in.

-

Speed of Conveyor Belt::

-

0-1500 mm/min

-

Heating Up Time::

-

15min

-

Temperature Control Range::

-

Room temperature - 300 ℃ / 572 ℉

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Online support

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YX

-

Use:

-

PCB Soldering

-

Voltage:

-

220V, 50HZ

-

Dimensions:

-

145cm*63cm*47cm

-

Rated Capacity:

-

4500W

-

Weight (KG):

-

130 KG

-

Heating Zone::

-

upper 3 / down 2

-

Soldering Area::

-

300 x 960 mm / 11.8 x 37.8 in.

-

Length of Heating Zone::

-

960 mm / 37.8 in.

-

Max Width of PCB Board::

-

300 mm / 11.8 in.

-

Speed of Conveyor Belt::

-

0-1500 mm/min

-

Heating Up Time::

-

15min

-

Temperature Control Range::

-

Room temperature - 300 ℃ / 572 ℉

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Online support

-

Certification:

-

CE

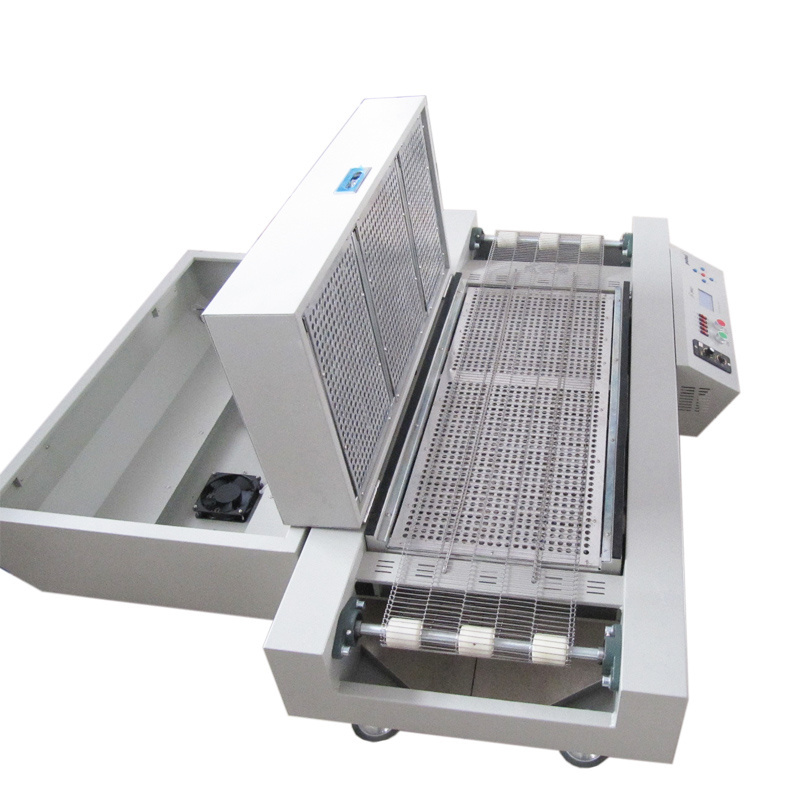

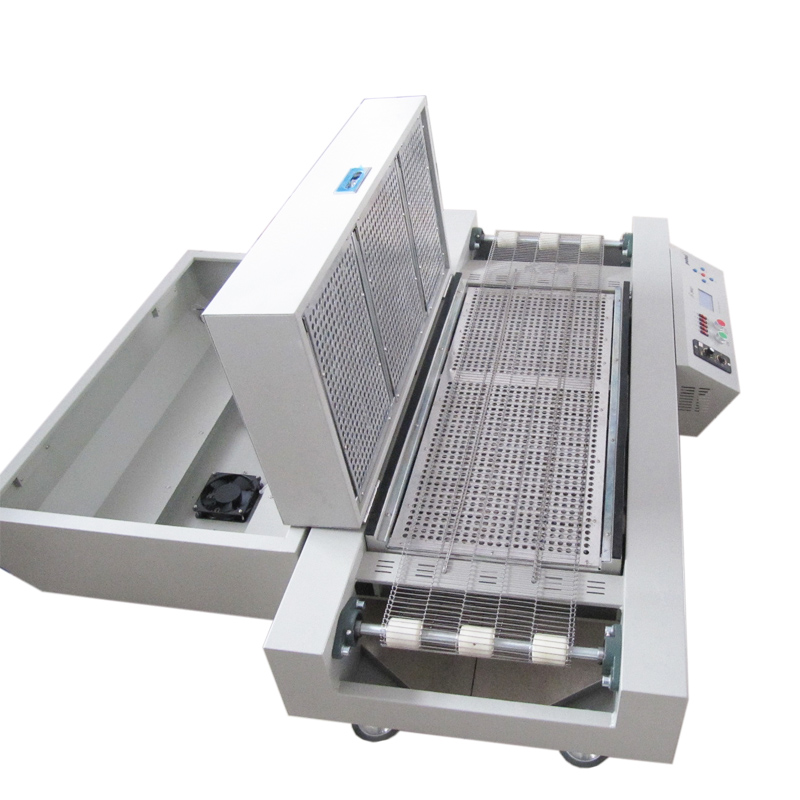

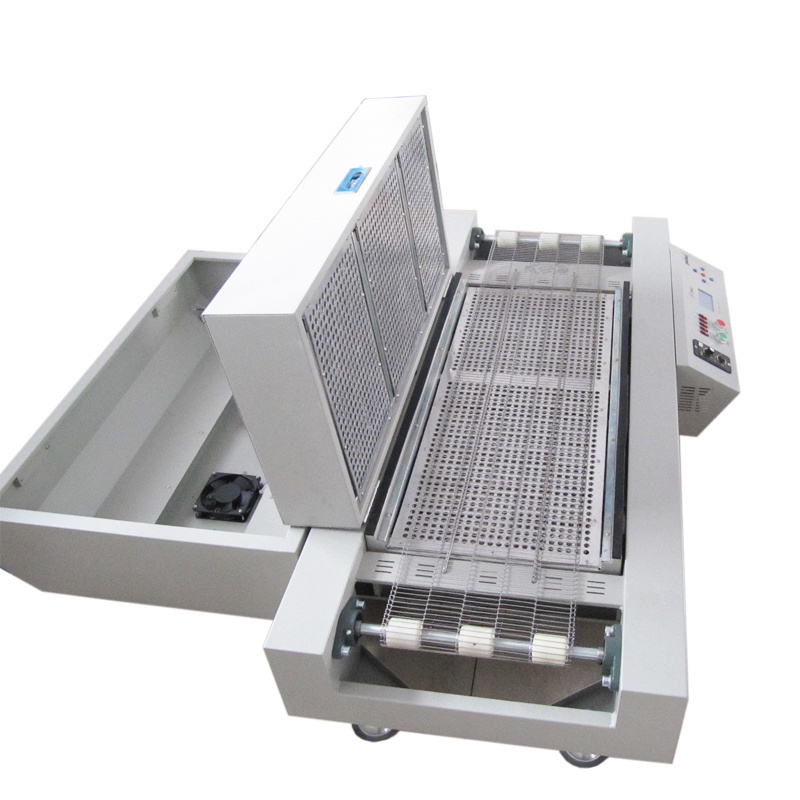

Intrduction

The Infrared IC Heater T960 is a microprocessor-controlled reflow-oven. This machine uses the intelligent level sirocco and rapid

infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. It is suitable for

high welding temperature lead-free solder paste and can be used for effectively soldering various SMT and BGA components.

infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. It is suitable for

high welding temperature lead-free solder paste and can be used for effectively soldering various SMT and BGA components.

Features

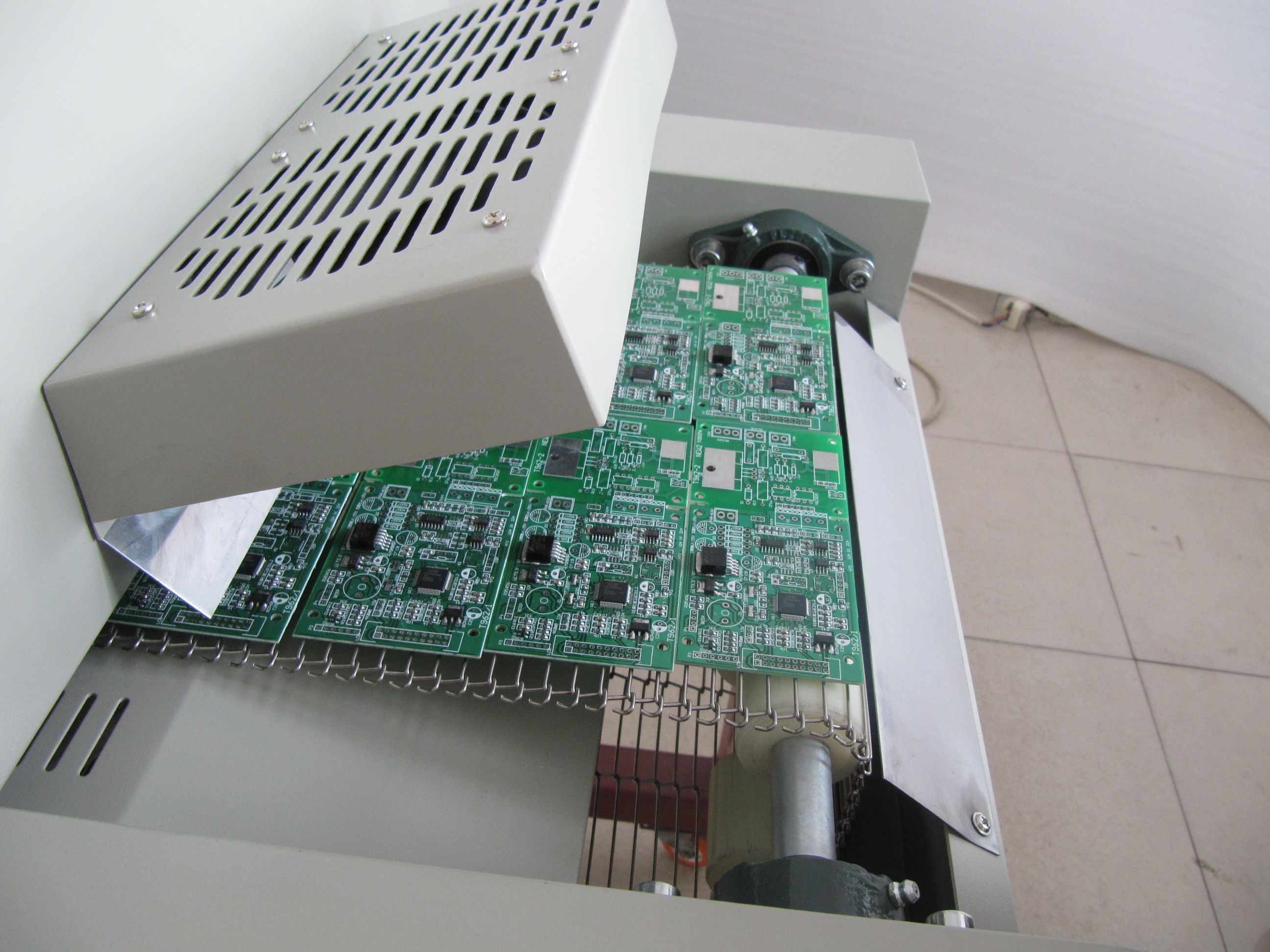

1.This machine selects infrared and hot air heating tchnology ,equipped with special designed wind wheel.the speed is stable and the temp is uniform, especially suit for uninterrupted soldering the LED and BGA components.

2.This machine is equipped with the crawler-type conveyor and 5 temperature zones heating systems.Each zone uses independent PID controlling and up-down heating type,can make the inside temp more accurate and well-proportioned.About 15 minutes can let it heat up to the working temp.

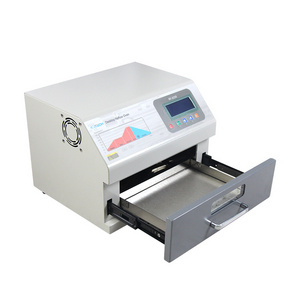

3.Intelligent temperature curve heating type, oversized capacity curve selection. Editable 8 temp curves can satisfy various welding technological requirements.

4.By using programmable technology, presetting the temperature curve memory storage function, can complete the whole welding process automatically.

5.Clear lcd screen, which integrates machine operation and function display, making the working state display more intuitive,heating process more clear, and operation more convenient.

6.Adopts the thermocouple temperature measurement and adds the compensation circuit,

makes the temperature measurement more accurate, the curve more perfect.

7.Using PID intelligent temperature control technology, makes the temp control more accurate.The imported large current solid-state relays can effectively avoid the IC or circuit boards being damaged due to the rapid or uninterrupted warming up.

2.This machine is equipped with the crawler-type conveyor and 5 temperature zones heating systems.Each zone uses independent PID controlling and up-down heating type,can make the inside temp more accurate and well-proportioned.About 15 minutes can let it heat up to the working temp.

3.Intelligent temperature curve heating type, oversized capacity curve selection. Editable 8 temp curves can satisfy various welding technological requirements.

4.By using programmable technology, presetting the temperature curve memory storage function, can complete the whole welding process automatically.

5.Clear lcd screen, which integrates machine operation and function display, making the working state display more intuitive,heating process more clear, and operation more convenient.

6.Adopts the thermocouple temperature measurement and adds the compensation circuit,

makes the temperature measurement more accurate, the curve more perfect.

7.Using PID intelligent temperature control technology, makes the temp control more accurate.The imported large current solid-state relays can effectively avoid the IC or circuit boards being damaged due to the rapid or uninterrupted warming up.

Part List

· 1 x T-960 Reflow Oven

· 1 x Accessory Kit (tool bag x 1, foot stand x 4, cable x 1, smoke tube x 2)

· 1 x Accessory Kit (tool bag x 1, foot stand x 4, cable x 1, smoke tube x 2)

Paramenters

|

Specification

|

|

|

|

Model

|

T-960

|

|

|

Heating Zone

|

upper 3 / down 2

|

|

|

Soldering Area

|

300 x 960 mm / 11.8 x 37.8 in

|

|

|

Voltage

|

220V, 50HZ

|

|

|

Length of Heating Zone

|

960 mm / 37.8 in

|

|

|

Max Width of PCB Board

|

300 mm / 11.8 in

|

|

|

Rated Power

|

4.5KW

|

|

|

Speed of Conveyor Belt

|

0-1500 mm/min

|

|

|

Heating Up Time

|

15min

|

|

|

Temperature Control Range

|

Room temperature - 300 ℃ / 572 ℉

|

|

|

Temperature Control Accuracy

|

± 1℃

|

|

|

Temperature Distribution Deviation

|

± 2℃

|

|

|

L*W*H(mm)

|

1450*630*470

|

|

|

Machine Weight

|

98KG

|

|

|

Packing Weight

|

130KG

|

|

Intelligent Heating

PID temperature control, fast infrared radiation, and smooth wind circulation are three key elements of the heating system. The non-contact output of imported high-current solid-state relays can effectively avoid damage to IC or circuit boards, making the entire welding process more scientific and safe

Eight Temperature Waves

This SMD/SMT reflow oven can provide eight kinds of stored temperature parameter waves as options to meet the requirements of various welding processes, and it has mobile heating and cooling functions. Besides, the entire welding process is auto-completed after you preset the wave. So you can say it is easy to use.

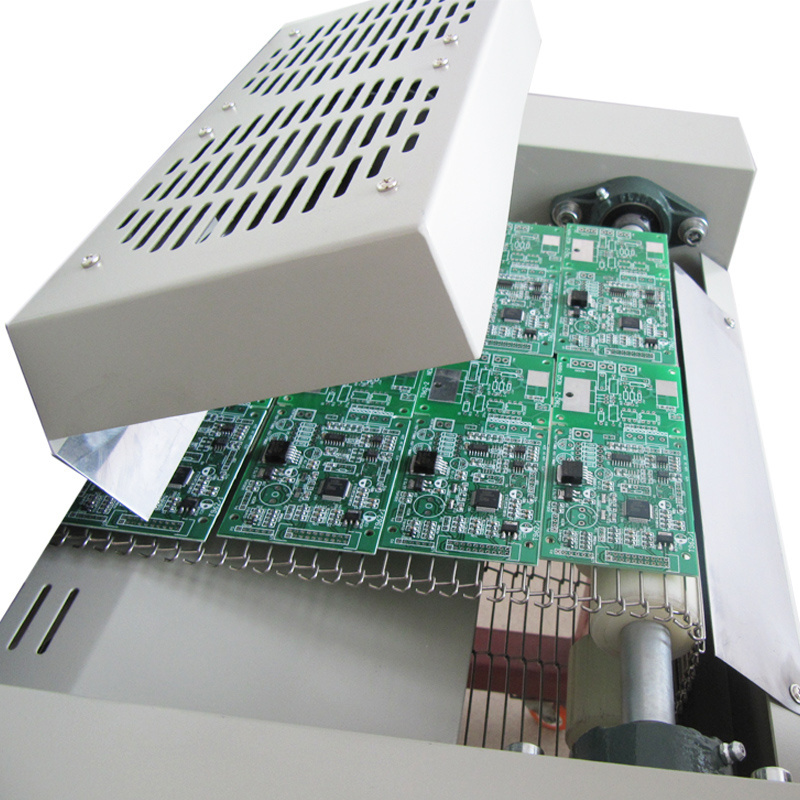

Wide Application

The T-960 reflow soldering machine is able to solder small parts of most PCB boards, for example, CHIP, SOP, PLCC, QFP, BGA, etc.It is the ideal rework solution from single runs to on-demand small batch production.

Packing details

Certifications

Wenzhou Yingxing Technology Co.,Ltd

Specialises in SMT Production Line

(PNP Machine)

more than 9 years

Our Services

1.Video technical support

2.24-hour online support

3.Goods tracking support

4.Free broken parts(With 1 YEAR warranty)

FQA

Q:How is the training?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

A:Yes

Related Products

Hot Searches