- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dongyue Brand AAC Block

-

Model Number:

-

B05 AAC Block

-

Color:

-

White Aac Block

-

Sound Reduction:

-

30-60Db

-

Thermal Conductivity:

-

0.132 W/(m.k)

-

Fireproof:

-

4 Hours

-

Dry Shrink Coefficient:

-

0.5mm/m

-

Average Compressive Strength:

-

3.5~5N/mm2

-

Weight:

-

520kg/m3

-

Certificate:

-

ISO9001-2000 :CE

-

Raw material:

-

Sand;lime;gypsum;aluminium powder;cement

-

Strength:

-

5.0Mpa

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dongyue Brand AAC Block

-

Model Number:

-

B05 AAC Block

-

Color:

-

White Aac Block

-

Sound Reduction:

-

30-60Db

-

Thermal Conductivity:

-

0.132 W/(m.k)

-

Fireproof:

-

4 Hours

-

Dry Shrink Coefficient:

-

0.5mm/m

-

Average Compressive Strength:

-

3.5~5N/mm2

-

Weight:

-

520kg/m3

-

Certificate:

-

ISO9001-2000 :CE

-

Raw material:

-

Sand;lime;gypsum;aluminium powder;cement

-

Strength:

-

5.0Mpa

lepin building blocks lightweight concrete blocks adopting German ytong technology

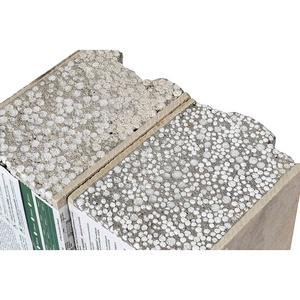

Autoclaved Aerated Concrete (AAC) is a siliceous material (sand, fly ash and silicon tailings such as waste porcelain clay, stone processing waste materials, blast furnace slag, etc.) and calcareous materials (lime, cement) as the main raw material, mixing fat gas agent (aluminum powder), by ingredients, mixing, casting, pre-raising, cutting, autoclave, curing process made of light porous silicate products, because by the hair contains a lot of gas even after the small pores, hence the name of aerated concrete.

1. Lightweight : Aerated concrete density is usually 400-900 kg/m3(according to the market),

which is 1/3 of clay block and 1/5 of common concrete.

2.Fireproof : Most of the major raw materials is inorganic material s, so it has good fire resistance ,

and do not emit harmful gases when meet fire

3.Sound insulation : As the material inside has a large numbers of the pores and porous, which has a

good thermal insulation properties .

4.Thermal Insulation : Thermal conductivity is 0.9-0.22 W/(MK), which is 1/4 of clay bricks.

5 .Anti-seismic : The same building structure, improve the two seismic than the brick level.

F orm 1 T he blocks specification and size ( Unit : millimeter )

|

Length (L) |

Width (B) |

Height (H) |

|

600 |

100 120 125 150 180 200 240 250 300 |

200 240 250 300 |

F orm 2 size d eviation and appearance

|

Name |

standard |

|||

|

T op-grade product(A) |

Q ualified product(B) |

|||

|

S ize deviation

|

length |

L |

±3 |

±4 |

|

width |

W |

±1 |

±2 |

|

|

height |

H |

±1 |

±2 |

|

|

C orner/ angle with lack |

T he min size can not over(mm) |

0 |

30 |

|

|

T he max size can not over(mm) |

0 |

70 |

||

|

If appear the above mentioned lack,the amount can not over piece |

0 |

2 |

||

|

Crack length |

If the crack that across two sides, the total crack ’ s length can not over the total sides length ’ s |

0 |

1/3 |

|

|

A ny crack ’ s length can not over the flat ’ s size of |

0 |

1/2 |

||

|

If appear the crack the above mentioned , can not over /number |

0 |

2 |

||

|

B urst,mold sticking and damaged depth can not over/mm |

10 |

30 |

||

|

P lane flexure |

impermissibility |

|||

|

F ace loosen,slip crack |

impermissibility |

|||

|

F ace oil stain |

impermissibility |

|||

F orm3 Block ’ s compression strength of cuber meter ( Unit : Mpa)

|

S trength classification |

compression strength of cuber meter |

|

|

average value ≥ |

single unit min value ≥ |

|

|

A1.0 |

1.0 |

0.8 |

|

A2.0 |

2.0 |

1.6 |

|

A2.5 |

2.5 |

2.0 |

|

A3.5 |

3.5 |

2.8 |

|

A5.0 |

5.0 |

4.0 |

|

A7.5 |

7.5 |

6.0 |

|

A10.0 |

10.0 |

8.0 |

Form 4 the dry density of the blocks ( Unit :Kg/m3)

|

D ry density classification |

B03 |

B04 |

B05 |

B06 |

B07 |

B08 |

|

|

D ry density |

T op-grade product(A)≤ |

300 |

400 |

500 |

600 |

700 |

800 |

|

Q uality product(B)≤ |

325 |

425 |

525 |

625 |

725 |

825 |

|

Form 5 the strength classified of the blocks

|

D ry density classification |

B03 |

B04 |

B05 |

B06 |

B07 |

B08 |

|

|

strength classified |

T op-grade product(A)≤ |

A1.0 |

A2.0 |

A3.5 |

A5.0 |

A7.5 |

A10.0 |

|

Q uality product(B)≤ |

A2.5 |

A3.5 |

A5.0 |

A7.5 |

|||

Form 6 the dry shrinkage ,frost resistance,heat conductivity

|

D ry density classification |

B03 |

B04 |

B05 |

B06 |

B07 |

B08 |

||

|

dry shrinkage value |

standard method (mm/m)≤ |

0.50 |

||||||

|

q uick m ethod (mm/m)≤ |

0.80 |

|||||||

|

frost resistance |

Q uality loss/%≤ |

5.0 |

||||||

|

A fter freezed strength /Mpa≥ |

T op-grade product(A) |

0.8 |

1.6 |

2.8 |

4.0 |

6.0 |

8.0 |

|

|

Q uality product(B) |

2.0 |

2.8 |

4.0 |

6.0 |

||||

|

heat conductivity[W/(m.k)≤

|

0.10 |

0.12 |

0.14 |

0.16 |

0.18 |

0.20 |

||

|

|

||||||||