- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V,50Hz,3P(Or as request)

-

Power:

-

9.5kw

-

Dimension(L*W*H):

-

about 6m*0.8m*1.3m

-

Weight:

-

3000 kg

-

Profile:

-

C/U/Omega/L/angle

-

Raw material:

-

Galvanized steel,carbon steel

-

Material thickness:

-

0.3-1.5mm(Or as request)

-

Cutting type:

-

Flying cut(Cut without stop)

-

Automation:

-

Automatic

-

Control system:

-

PLC

-

Speed:

-

customer's request

-

Size:

-

One machine can produce different sizes

-

Roller material:

-

Cr12 with quenched treatment

-

After-sales Service Provided:

-

Life Time Technology Service

Quick Details

-

Production Capacity:

-

0-20m/min

-

Place of Origin:

-

Hebei China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V,50Hz,3P(Or as request)

-

Power:

-

9.5kw

-

Dimension(L*W*H):

-

about 6m*0.8m*1.3m

-

Weight:

-

3000 kg

-

Profile:

-

C/U/Omega/L/angle

-

Raw material:

-

Galvanized steel,carbon steel

-

Material thickness:

-

0.3-1.5mm(Or as request)

-

Cutting type:

-

Flying cut(Cut without stop)

-

Automation:

-

Automatic

-

Control system:

-

PLC

-

Speed:

-

customer's request

-

Size:

-

One machine can produce different sizes

-

Roller material:

-

Cr12 with quenched treatment

-

After-sales Service Provided:

-

Life Time Technology Service

Product Description

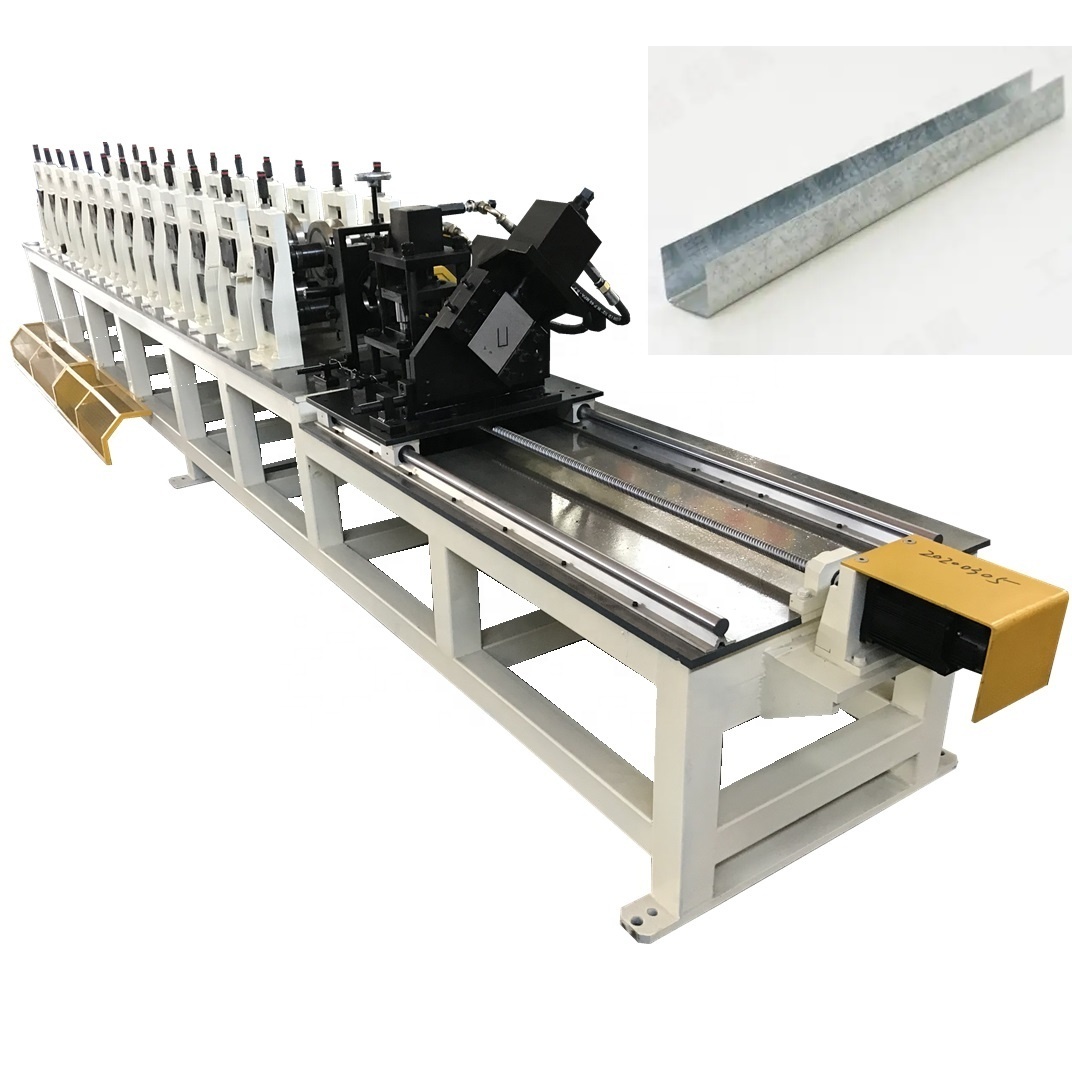

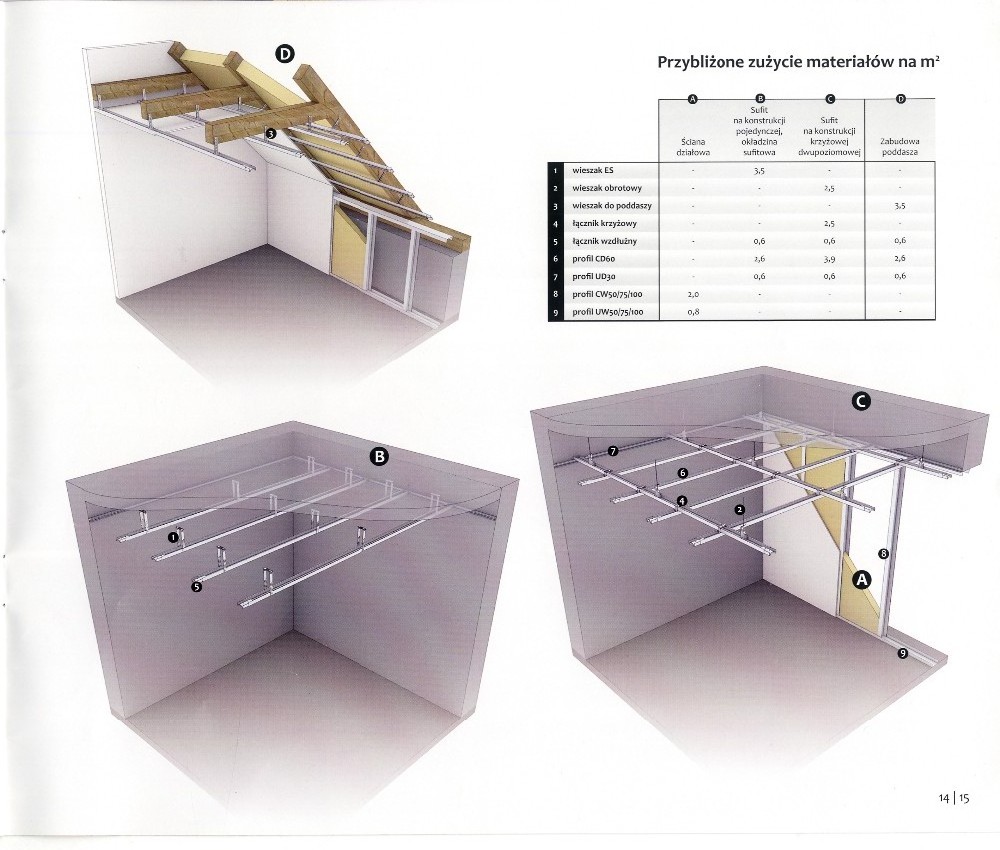

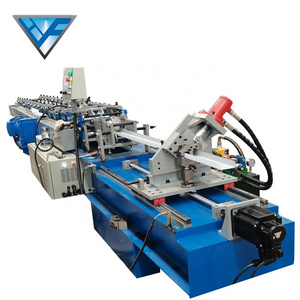

ZTRFM CE ISO Certificated Roof Truss Press U Stud C Channel Roll Forming Machine

ZTRFM CE ISO Certificated Roof Truss Press U Stud C Channel Roll Forming Machine

is to produce the l

ight steel keel which is for the roof truss.The application of the finished products for your reference.

|

ZTRFM CE ISO Certificated Roof Truss Press U Stud C Channel Roll Forming Machine

|

|

|

|

|

||||

|

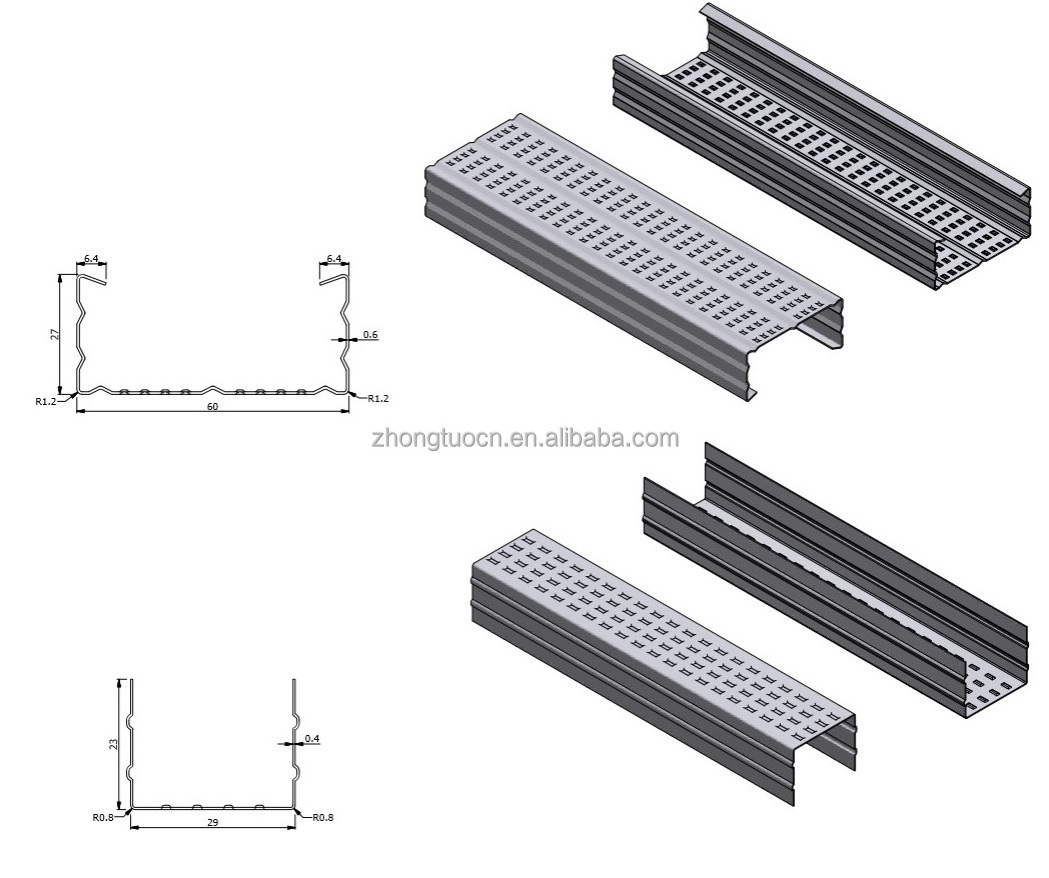

1.Formed Material

|

PPGI,GI,AI

|

|

Thickness:0.5-1.2mm

|

|

||||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

|

Manual decoiler(will give you as free)

|

|

||||

|

3.Main body

|

Roller station

|

|

12 rows(As your requirement)

|

|

||||

|

|

Diameter of shaft

|

|

50mm solid shaft

|

|

||||

|

|

Material of rollers

|

|

45# steel, hard chrome plated on the surface

|

|

||||

|

|

Machine body frame

|

|

Metal steel welded

|

|

||||

|

|

Drive

|

|

gearbox transmission

|

|

||||

|

|

Dimension(L*W*H)

|

|

5500*800*1200(customize)

|

|

||||

|

|

Weight

|

|

About 5T

|

|

||||

|

4.Cutter

|

Automatic

|

|

cr12mov material, no scratches, no deformation

|

|

||||

|

5.Power

|

Motor Power

|

|

11KW

|

|

||||

|

|

Hydraulic system power

|

|

7.5KW

|

|

||||

|

6.Voltage

|

380V 50Hz 3Phase

|

|

As your requirement

|

|

||||

|

7.Control system

|

Electric Box

|

|

Customized(famous brand)

|

|

||||

|

|

Language

|

|

English(Support multiple languages)

|

|

||||

|

|

PLC

|

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|

||||

|

18.Forming Speed

|

0-70m/min(customized)

|

|

The speed is adjustable

|

|

||||

Products Display

Decoiler

Double head,easy operation.

Receiving Table

With conveyor and receiving table,full automatic easy operation.

Hydraulic cutting device

None stoping high speed.

Roll Forming device

If you need high speed the machine will design for you as this type gearbox transmission,high speed and stable.

Feeding device

With handwheels for adjust feeding material thickness.

Portable PLC control system

Portable with machine design

Language customized,easy operation

Machines are customized as your drawing,here hot sale drawing profiles for your reference.

Recommend Products

Why Choose Us

Hot Searches