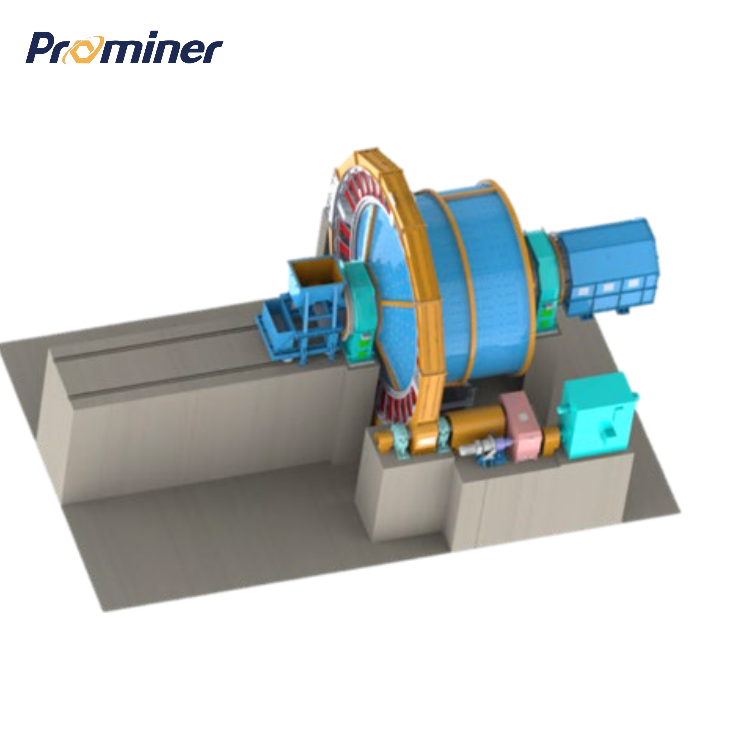

Application:

As primary and secondary grinding system for gold CIL plant, flotation plant, Iron ore magnetic separation plant and primary grinding system for natural graphite project.

|

Main Specification of SAG Mill

|

|

|

|

|

|

|

||||||

|

Model

|

Mill diameter

|

Mill length

|

Effective volume

|

Max.ball load

|

Rotation speed

|

Motor power

|

||||||

|

|

mm

|

mm

|

m3

|

t

|

r/min

|

kw

|

||||||

|

SAG-40×L

|

4000

|

1600-3600

|

19-42

|

13-29

|

16.2

|

310-710

|

||||||

|

SAG-45×L

|

4500

|

1800-4100

|

27-61

|

19-43

|

15.3

|

470-1100

|

||||||

|

SAG-50×L

|

5000

|

2000-4500

|

38-83

|

27-58

|

14.5

|

700-1500

|

||||||

|

SAG-55×L

|

5500

|

2200-5000

|

51-112

|

36-78

|

13.8

|

960-2200

|

||||||

|

SAG-61×L

|

6100

|

2400-5500

|

69-152

|

48-106

|

13.1

|

1400-3100

|

||||||

|

SAG-67×L

|

6700

|

2700-6000

|

93-201

|

65-140

|

12.5

|

2000-4300

|

||||||

|

SAG-73×L

|

7300

|

2900-6600

|

120-264

|

84-184

|

12

|

2600-5900

|

||||||

|

SAG-80×L

|

8000

|

3200-7200

|

160-347

|

112-242

|

11.4

|

3600-8100

|

||||||

|

SAG-86×L

|

8600

|

3400-7700

|

197-429

|

137-299

|

11

|

4600-10000

|

||||||

|

SAG-92×L

|

9200

|

3700-8300

|

246-530

|

172-370

|

10.7

|

5900-13000

|

||||||

|

SAG-98×L

|

9800

|

3900-8800

|

296-640

|

206-446

|

10.3

|

7300-16000

|

||||||

|

SAG-104×L

|

10400

|

4200-9400

|

359-770

|

250-537

|

10

|

910-20000

|

||||||

|

SAG-110×L

|

11000

|

4400-9900

|

422-909

|

294-634

|

9.8

|

11000-25000

|

||||||