- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

hengyu002

-

Product Name:

-

Injection Plastic Mould part

-

Material:

-

plastic and rubber

-

Mould base:

-

Non-Standard Plastic Injection Mould

-

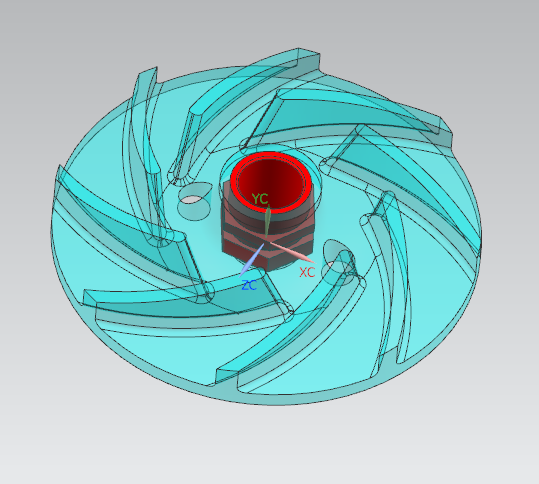

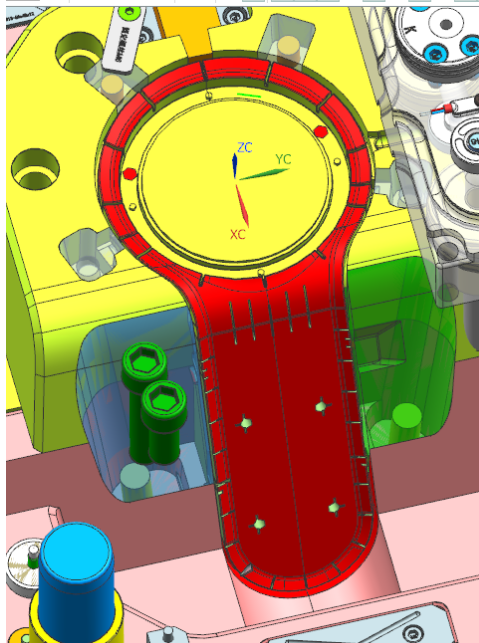

Design software:

-

2D/3D/CAD/DWG//STEP/PDF/UG

-

Size:

-

Drawing

-

Package:

-

Wooden Case Package

-

Mold Life:

-

300000~10000000 products

-

Tolerance:

-

0.01- +/-0.005mm

-

Delivery Time:

-

25days

-

samples:

-

3D printing

Quick Details

-

Processing Service:

-

Moulding, Cutting, injection, CNC machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hengyu

-

Model Number:

-

hengyu002

-

Product Name:

-

Injection Plastic Mould part

-

Material:

-

plastic and rubber

-

Mould base:

-

Non-Standard Plastic Injection Mould

-

Design software:

-

2D/3D/CAD/DWG//STEP/PDF/UG

-

Size:

-

Drawing

-

Package:

-

Wooden Case Package

-

Mold Life:

-

300000~10000000 products

-

Tolerance:

-

0.01- +/-0.005mm

-

Delivery Time:

-

25days

-

samples:

-

3D printing

Products Description

Custom Plastic Part+Surface Treatment

China Mold Manufacturer Professional Plastic Injection Molding Factory

1. Start from part design analysis.2. Mold design drawing and DFM report available so you can see how is the mold going to be

before mold making.

3. If product is complex,moldflow report will be present as well.

4. In house mold making shop ensure you mold quality under well control.

5. Normally it takes 20-40 days to make mold,precise time depends on part design.

6. Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect.

7. We can also provide different surface treatment for injection molded parts.

8. Commonly use surface treatment for injection molded parts as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI.

9. Beside making injection molded parts,we also provide printing,welding,assembly and packing service.

1. Start from part design analysis.2. Mold design drawing and DFM report available so you can see how is the mold going to be

before mold making.

3. If product is complex,moldflow report will be present as well.

4. In house mold making shop ensure you mold quality under well control.

5. Normally it takes 20-40 days to make mold,precise time depends on part design.

6. Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect.

7. We can also provide different surface treatment for injection molded parts.

8. Commonly use surface treatment for injection molded parts as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI.

9. Beside making injection molded parts,we also provide printing,welding,assembly and packing service.

About the injection mold

|

Mold Material

|

|

45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc .

|

|

|

|||

|

Mold Type

|

|

Plastic Injection Molding

|

|

|

|||

|

Product Material

|

|

ABS, PA, PA66+GF, POM, PC, PP, PET, TPE, PVC, HDPE, etc

|

|

|

|||

|

Mold Standard

|

|

HASCO, DME, MISUMI, JIS, LKM, etc.

|

|

|

|||

|

Mold Tooling Equipment

|

|

Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine

|

|

|

|||

|

Injection Mold Machine

|

|

19 Sets With Model 90T to 1100T

|

|

|

|||

|

Gate Type

|

|

Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

|

|

|

|||

|

Runner Type

|

|

Cold Runner or Hot Runner

|

|

|

|||

|

Cavity

|

|

Single or Multi cavities

|

|

|

|||

|

Mold Life

|

|

45#:50,000 to 100,000 shots

P20:100,000 to 200,000 shots 718: 200,000 to 300,000 shots H13: 300,000 to 500,000 shots |

|

|

|||

|

Lead Time

|

|

Generally mold making will take around 30 days and 7-10 day to mass production

|

|

|

|||

|

Package

|

|

Wooden packing box for molds and Generally inner packed in opp bags, outside packed in standard export carton with shipping marks,

and the cartons will be full of bubble bags |

|

|

|||

Products Detailed

Hengyu plastic

we provides on-stop service for plastic product customizing works.We provide mold design,precision plastic mold making,custom

best quality plastic injection molding,Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging

Services.

best quality plastic injection molding,Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging

Services.

Product Design

We Provide Product Design Service As Customer's Request.

Mold Design

We will communicate&exchange the opinion with customers during Mold Deisgn

Mold Making

Start to manufacture, we will sent photos to show tooling process.

Provide the sample

Once the sample finish,we will send the sample to customer confirm

Mass Production

After customer confirmed the sample, we will start mass production plastic products

Assembly

We also make the packaging box as customer request.

Painting&Coating .

We can provide coating and rubber coating service for your customers.

Printing

We Also Provide Silk Screen Printing, Pad Printing, Heat Transfer Print Service.

Packaging and shipping

We also make the packaging box as customer request.

Factory information

Customers visit

Customers comments

Hot Searches