|

Cetificates

|

SGS, GB/T19001-2016/ISO9001:2015, Material Cert, etc.

|

|

|

|

|

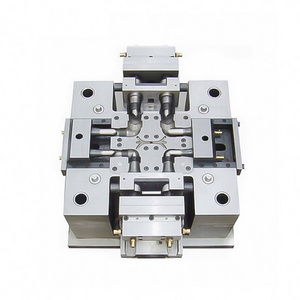

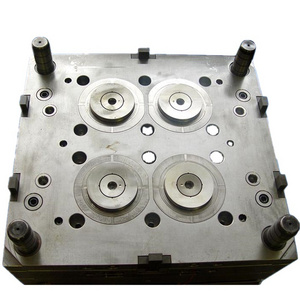

Capabilities

|

3D printing, CNC machining, Mold manufacturing, Injection Molding, etc.

|

|

|

|

|

Drawing, File Formats

|

SolidWorks, Pro/Engineer, STP, IGS, STEP, AutoCAD(DWG, DXF), PDF, JPG, etc.

|

|

|

|

|

Machinable Tolerance

|

±0.005mm, 100% QC inspection before delivery, providing test report

|

|

|

|

|

Optional Material

|

PA, PP, PC, PE, POM, PVC, PS, PMMA, PU, PPS, PEEK, ABS, ASA, TPR, Rubber, Silicone, Aluminum, Steel, Stainless steel, Brass, Copper, Bronze, etc.

|

|

|

|

|

Heat Treatment

|

Quenching, Tempering, Annealing, Normalizing, etc. (Rockwell Hardness)

|

|

|

|

|

|

Powder Coating, Painting, Zinc/ Chrome/ Nickel Plating, PVD,

Polishing, Brushing, Sand Blasting,

Anodizing, Passivating, Rubber Coating, etc.

|

|

|

|

|

Logo, Color, Grain

|

Customizable (Pantone Color Card, AI Vector Picture)

|

|

|

|

|

Quality Control

|

CMM, Projector,Image Measurement Instrument, Tool Microscope, Marble Platform,

Roughness Measurement, Hardness Tester, Salt Spray Tester,

Micrometer, Automatic Height Gauge, Go-No Go Fixed Gauge, Micrometer, Vernier Caliper, etc.

|

|

|

|

|

Package

|

Wooden Pallet/ Wooden Case/ Carton/ Foam Box With Bubble wrap/ Plastic Bag/ Plastic Film/

Pearl Cotton/ Paper Piece, depending On Specific Project

|

|

|

|

|

MOQ

|

For injection molding service, small parts ≥1,000 pcs big parts ≥ 500 pcs

|

|

|

|

|

Lead Time

|

7-12 working days if mass production quantity ≤ 10,000 pcs

|

|

|

|

|

Trade Terms

|

EXW, FOB, CFR, CIF, DDP, etc.

|

|

|

|

|

Transportation

|

By Express/ Sea/ Air/ Land

|

|

|

|

|

Payment Terms

|

T/T, PAYPAL, Western Union, VISA, Mastercard, E-Checking, APPLE_PAY, GOOGLE_PAY, etc.

|

|

|

|