- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

1200 mm

-

Max. Table Load(kg):

-

5000

-

Travel (W-axis) (mm):

-

550 mm

-

Positioning Accuracy (X axis) mm:

-

0.005

-

Positioning Accuracy (Y axis) mm:

-

0.002

-

Positioning Accuracy (Z axis) mm:

-

0.002

-

Range of Spindle Speed(r.p.m):

-

3500 r.p.m

-

Spindle Motor Power(kW):

-

15/18.5

-

Production Capacity:

-

High

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DRC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5800*6100*3500

-

Weight (T):

-

22 T

-

Name:

-

Horizontal CNC boring milling machine

-

Product name:

-

CNC boring machine

-

X-axis travel (standard):

-

1700mm

-

Y-axis travel (standard):

-

1400mm

-

Z-axis travel (standard):

-

1200mm

-

W-axis travel (standard):

-

550mm

-

Spindle nose to worktable center:

-

70-1680mm

-

Spindle motor:

-

15/18.5

-

Control system:

-

FANUC

-

Weight:

-

22000kg

Quick Details

-

Table Size (mm):

-

1250/1250

-

Table Travel (X) (mm):

-

1700 mm

-

Table Travel (Y) (mm):

-

1400 mm

-

Table Travel (Z) (mm):

-

1200 mm

-

Max. Table Load(kg):

-

5000

-

Travel (W-axis) (mm):

-

550 mm

-

Positioning Accuracy (X axis) mm:

-

0.005

-

Positioning Accuracy (Y axis) mm:

-

0.002

-

Positioning Accuracy (Z axis) mm:

-

0.002

-

Range of Spindle Speed(r.p.m):

-

3500 r.p.m

-

Spindle Motor Power(kW):

-

15/18.5

-

Production Capacity:

-

High

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DRC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5800*6100*3500

-

Weight (T):

-

22 T

-

Name:

-

Horizontal CNC boring milling machine

-

Product name:

-

CNC boring machine

-

X-axis travel (standard):

-

1700mm

-

Y-axis travel (standard):

-

1400mm

-

Z-axis travel (standard):

-

1200mm

-

W-axis travel (standard):

-

550mm

-

Spindle nose to worktable center:

-

70-1680mm

-

Spindle motor:

-

15/18.5

-

Control system:

-

FANUC

-

Weight:

-

22000kg

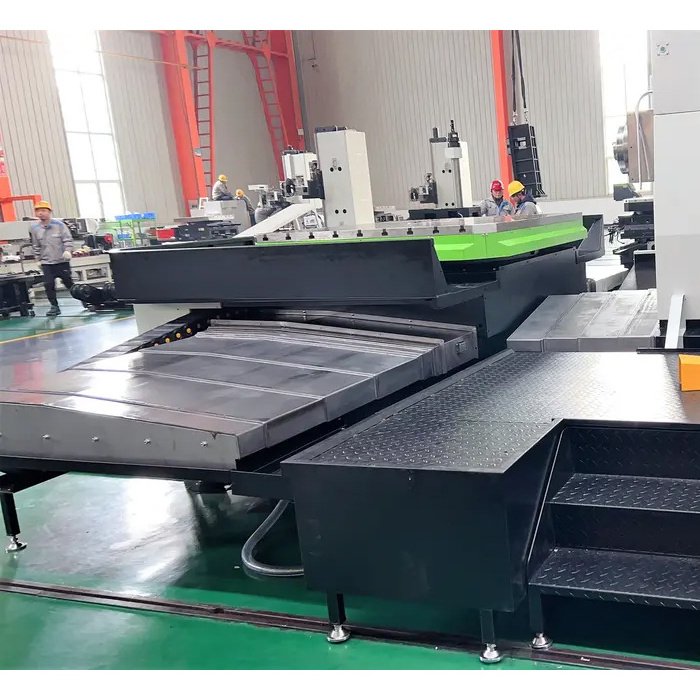

High Rigidity DBE110 Horizontal Cnc Horizontal Boring Milling Machine

Main Features

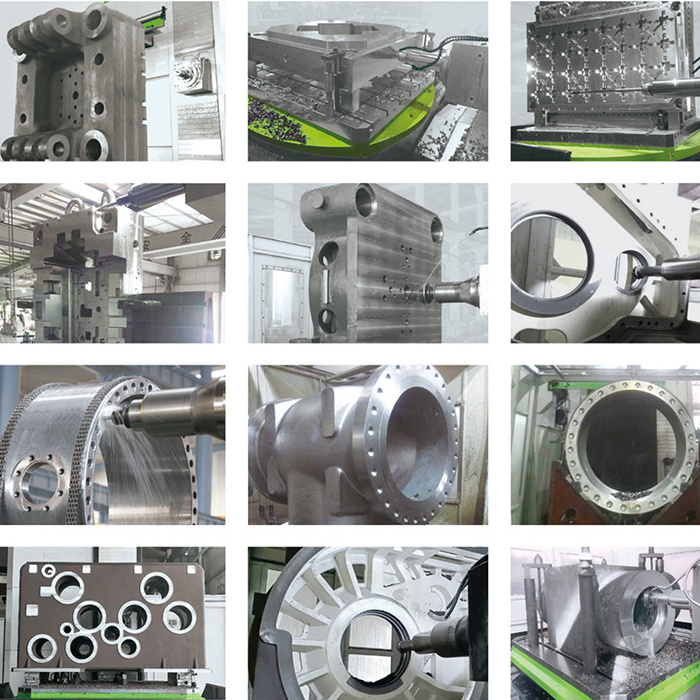

This product is mainly for the processing of the box parts to achieve a five-sided processing of one time clamping. The nose of the spindle can be extended to the workpiece, and the square ram can also be telescopic to facilitate deep milling and deep groove. It can meet the processing of products with high coaxial concentricity. It is equipped with a rotary table with a weight of 0.001. It can realize five-axis linkage machining, stable casting structure, strong shock resistance, bending resistance of the column and high anti-torsion rigidity. The uppermost side of the stroke end can also be stably processed to achieve the best performance of the product.

X/Y/Z Axis structures

Spindle

Gear type main shaft head are integrally cast molding, has a higher rigidity than the average combined type main shaft structure, improves the stability of the machine.

Spindle using large spacing, cylindrical rollers NN bearing ultra precision, ultra rigid, therefore has excellent processing capability for heavy cutting.

Main Parameter

|

Model

|

Unit

|

DBE110

|

||

|

Travel

|

|

|

||

|

X-axis travel(standard)

|

mm

|

1700

|

||

|

X-axis travel(optional)

|

mm

|

|

||

|

Y-axis travel(standard)

|

mm

|

1400

|

||

|

Y-axis travel(optional)

|

mm

|

|

||

|

Z-axis travel(standard)

|

mm

|

1200

|

||

|

Z-axis travel(optional)

|

mm

|

∕

|

||

|

W-axis travel(standard)

|

mm

|

550

|

||

|

Spindle

|

|

|

||

|

Spindle center to worktable surface

|

mm

|

0~1400

|

||

|

Spindle nose to worktable center

|

mm

|

-70~1680

|

||

|

Spinde diameter

|

mm

|

110

|

||

|

Spindle taper

|

|

BT50

|

||

|

Rotating spindle speed

(standard) |

rpm/min

|

35~2500

|

||

|

Rotating spindle speed

(optional) |

rpm/min

|

35~3500

|

||

|

Number of steps of rotating speed of spindle

|

|

2 Steps

|

||

|

Spindle drive mode

|

|

Belt

|

||

|

Spindle motor

|

Kw

|

Fanuc 15/18.5

|

||

|

Max.torque of spindle

|

Nm

|

1182/1457

|

||

|

Worktable

|

|

|

||

|

Table size

|

mm

|

1250*1250

|

||

|

Division angle

|

deg

|

1°

|

||

|

Reference aperture

|

mm

|

Φ75H7

|

||

|

Max. load on worktable

|

kg

|

5000

|

||

|

T-shot

|

mm

|

22H7*160*7

|

||

|

Precision

|

|

|

||

|

Positioning accuracy of rotary table

|

arc-sec

|

10″

|

||

|

Repeated Positioning accuracy of rotary table

|

arc-sec

|

3″

|

||

|

Positioning accuracy

|

mm

|

0.015

|

||

|

Repeated Positioning accuracy

|

mm

|

0.01

|

||

|

Drive Mode

|

|

|

||

|

XYZ-axis

|

|

Direct-drive

|

||

|

W-axis

|

|

Belt-drive

|

||

|

Y-axis counterweight

|

|

clump weight

|

||

|

Feed speed

|

|

|

||

|

Cutting speed X/Y/Z/W

|

m/min

|

10/10/10/6

|

||

|

Rapid traverse speed X/Y/Z/W

|

m/min

|

12/12/12/8

|

||

|

Configuration of motor

|

|

|

||

|

X_axis motor

|

|

βiS 30

|

||

|

Y_axis motor

|

|

βiS 40 B

|

||

|

Z_axis motor

|

|

βiS 40

|

||

|

Spindle motor

|

|

βiⅠP 30

|

||

|

B_axis motor

|

|

βiS 30

|

||

|

Tool magazine(Optional)

|

|

|

||

|

Capacity of tool magazine

|

|

40

|

||

|

Max. tool weight

|

kg

|

25

|

||

|

Max. tool length

|

mm

|

500

|

||

|

Max. tool diameter (No adjacent tool)

|

mm

|

Φ125/250

|

||

|

Others

|

|

|

||

|

Air pressure

|

kgf/cm²

|

6

|

||

|

Voltage

|

kva

|

65

|

||

|

Tank Capacity

|

L

|

480

|

||

|

Floor area

(length*width*height) |

mm

|

5800*6100*3500

|

||

|

Weight

|

kg

|

22000

|

||

Worktable

Indexing action is kept reliable and stable dependent on drive of large-diameter sliding surface and double gears 90°locating pins independently researched .

In addition hydraulic and T-bolts are used for solid clamp. Furthermore, backboard is used to prevent float of worktable under strong clamp of hydraulic and T-bots.

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year

.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer's installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.