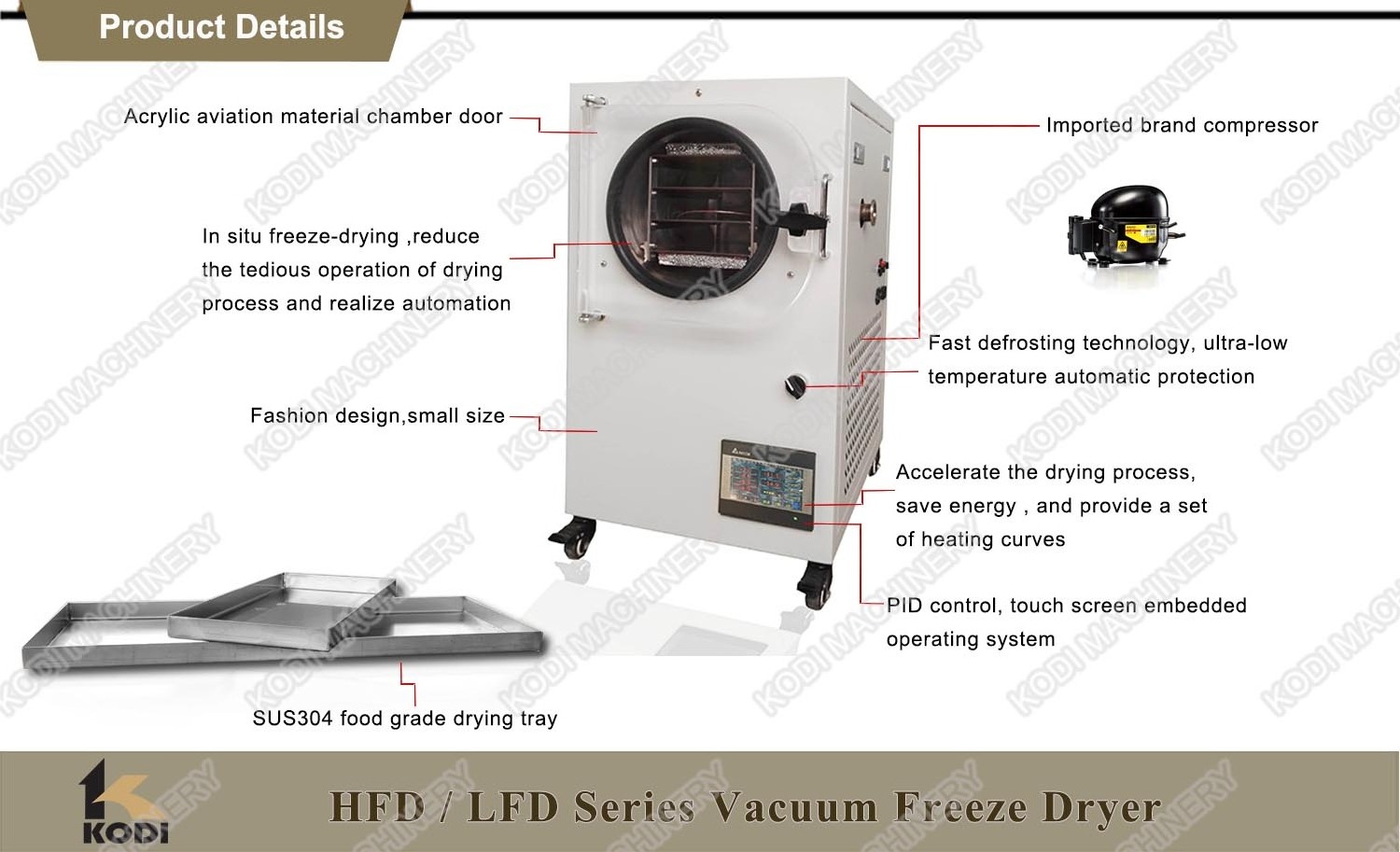

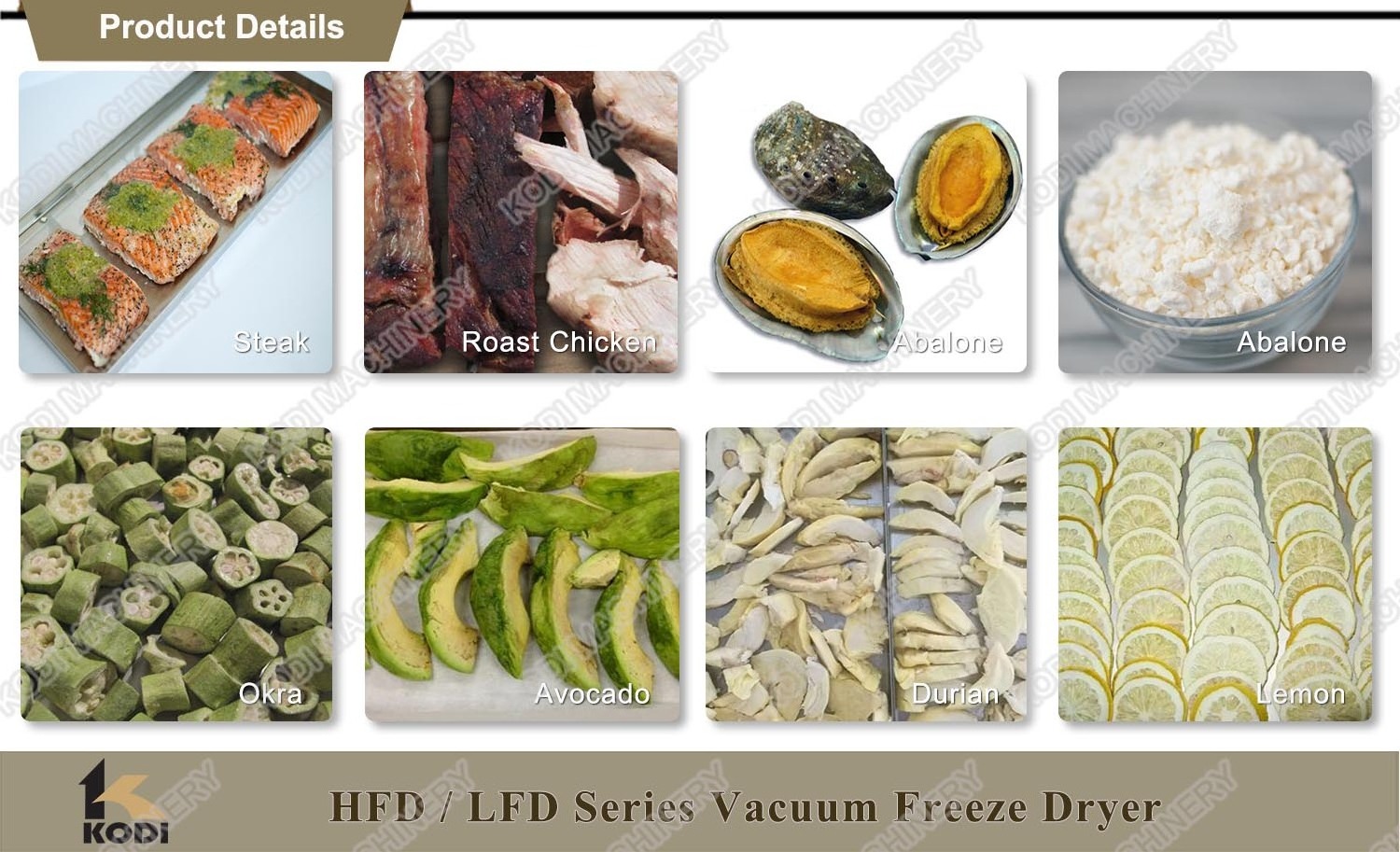

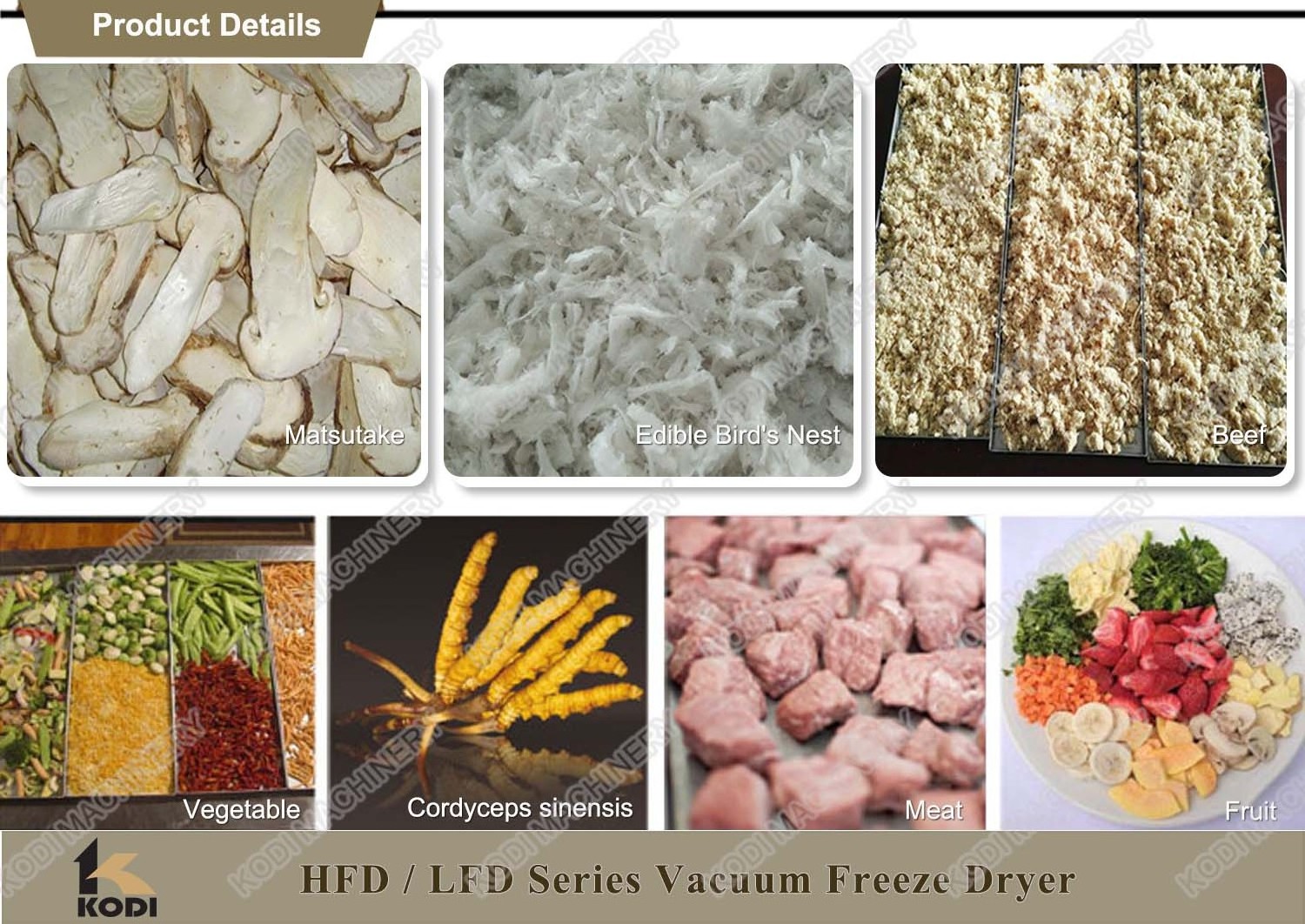

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KODI

-

Voltage:

-

220-440V

-

Power:

-

1-8kw

-

Dimension(L*W*H):

-

Depend on different model

-

Weight (KG):

-

500

-

Product Name:

-

Food Industry Mini Vacuum Freeze Dryer For Home or Lab Use

-

Lyophilizing acreage:

-

0.1-0.6m2

-

Production capacity:

-

1-8kg/batch

-

Shelf spacing:

-

45-50 mm

-

Shelf quantity:

-

3-5floors

-

Cold trap temperature:

-

-40~-60℃

-

Ultimate vacuum:

-

10-15pa

-

Spare parts:

-

supply the whole lifetime

-

Weight:

-

50-120kg

Quick Details

-

Type:

-

Vacuum Drying Equipment

-

Drying Capacity (kg):

-

1kg

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KODI

-

Voltage:

-

220-440V

-

Power:

-

1-8kw

-

Dimension(L*W*H):

-

Depend on different model

-

Weight (KG):

-

500

-

Product Name:

-

Food Industry Mini Vacuum Freeze Dryer For Home or Lab Use

-

Lyophilizing acreage:

-

0.1-0.6m2

-

Production capacity:

-

1-8kg/batch

-

Shelf spacing:

-

45-50 mm

-

Shelf quantity:

-

3-5floors

-

Cold trap temperature:

-

-40~-60℃

-

Ultimate vacuum:

-

10-15pa

-

Spare parts:

-

supply the whole lifetime

-

Weight:

-

50-120kg

Food Industry Mini Vacuum Freeze Dryer For Home or Lab Usee

1. Freeze Dryer / Mini Freeze Dryer / Mini Vacuum Freeze Dryer

2. Made of SS304

3. Easy operation and maintenance

4. GMP standard

Mini Vacuum Freeze Dryer Introuction

The major parts of KODI VMini Vacuum Freeze Dryer are imported from other countries, characterized by stability and reliability and many other advantages, such as good-looking appearance, small volume, light weight and easy operation. They can be widely applied to many fields, such as foods, biological products, chemical engineering, traditional Chinese materials and health care products. Because the drying process is carried out at low temperature, it can be used for some materials such as proteins, which are easy to be denatured at high temperature, and can ensure that the properties of other compounds will not change.

Mini Freeze Dryer Features:

1. The appearance is fashionable and the dimension is small and exquisite.

2. The transparent organic glass door is helpful in observing the freeze-drying process of materials.

3. Dish and inner tank are made of SUS304 stainless steel, which guarantees the safety of product.

4. The imported key components are characterized by low noise, great power, high quality and high performance.

5. Operate on touch screen, one key start and automatical control freeze-drying process, easy and convenient operation.

6. Set and real-timely adjust freeze-drying technology by requirement and show the freeze-drying data and curve.

7. Advanced system, small running current and low energy consumption.

8. Fast defrosting tehnique and automatic protection for overheat.

9. Patented products with advanced technology.

10. The vacuum pump is connected by international standard KF quick connector.

Mini Vacuum Freeze Dryer Operating principle

Mini Vacuum Freeze Dryer is one of the gentlest ways to dry. It is based on the sublimation principle, that is, the solid phase directly into the gas phase of this physical phenomenon. The freeze-dried material is placed in a vacuum drying chamber for drying, and the water vapor produced by the cold trap is condensed to form ice, so as to achieve the purpose of eliminating water vapor. Vacuum pump is used to discharge the air in the drying room, not including water vapor.

The baffle plate is provided with a heating device, and the heat is transferred to the material through the conduction function to provide the energy needed for sublimation. When the free water in the material is sublimated, the internal bound water can also be removed from the material at a very low vacuum. This drying process is considered to be the last stage of drying, analytical drying.

Mini Freeze DryerTechnical Parameters

|

Model |

TF-HFD-1 |

TF-HFD-4 |

TF-HFD-6 |

TF-LFD-1 |

TF-LFD-4 |

TF-LFD- 6 |

TF-LFD-1A |

TF-LFD-4A |

TF-LFD-6A |

|

Lyophilizing acreage(m2) |

0.1 |

0.4 |

0.6 |

0.1 |

0.4 |

0.6 |

0.1 |

0.4 |

0.6 |

|

Cold trap temperature(℃) |

-40 |

-45 |

-60 |

||||||

|

Ultimate vacuum(Pa) |

15 |

15 |

10 |

||||||

|

Material handing capacity(kg/Wholesale) |

1-2 |

4-6 |

6-8 |

1-2 |

4-6 |

6-8 |

1-2 |

4-6 |

6-8 |

|

Shelf Spacing(mm) |

45 |

45 |

50 |

45 |

45 |

50 |

45 |

45 |

50 |

|

Power Supply |

220V;50HZ |

220V;50HZ |

220V;50HZ |

||||||

|

Power(W) |

750W |

1100W |

2300W |

750W |

1100W |

2300W |

1700W |

2500W |

4500W |

|

Equipment weight(Kg) |

50 |

80 |

120 |

50 |

80 |

120 |

50 |

80 |

120 |

|

Shelf Dim(mm) |

140*278; 3floor |

200*450 4floor |

300*400 5floor |

140*278; 3floor |

200*450 4floor |

300*400 5floor |

140*278; 3floor |

200*450 4floor |

300*400 5floor |

|

External Dimensions(cm) |

40*55*70 |

51*70*85 |

70*80*130 |

40*55*70 |

51*70*85 |

70*80*130 |

55*62*85 |

60*70*105 |

70*80*130 |