- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5-80KW

-

Dimension(L*W*H):

-

Depends on capacity

-

Weight:

-

850 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Commodity:

-

Stainless Steel Beer fermenter fermentation tank for Brewing System

-

Material:

-

Stainless Steel 304 316

-

Jacket Pressure (Mpa):

-

0.3

-

Inner Pressure (Mpa):

-

0.2

-

Capacity:

-

100L~100T

-

Control system:

-

Automatic/Semi-automatic Control

-

Heat Insulation:

-

Polyurethane/Aluminum silicate

-

Heat Method:

-

Steam heating/Electrical heating

-

Surface treatment:

-

Mirror polishing fineness of Ra0.4

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TANLET

-

Voltage:

-

220/380V

-

Power:

-

5-80KW

-

Dimension(L*W*H):

-

Depends on capacity

-

Weight:

-

850 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Commodity:

-

Stainless Steel Beer fermenter fermentation tank for Brewing System

-

Material:

-

Stainless Steel 304 316

-

Jacket Pressure (Mpa):

-

0.3

-

Inner Pressure (Mpa):

-

0.2

-

Capacity:

-

100L~100T

-

Control system:

-

Automatic/Semi-automatic Control

-

Heat Insulation:

-

Polyurethane/Aluminum silicate

-

Heat Method:

-

Steam heating/Electrical heating

-

Surface treatment:

-

Mirror polishing fineness of Ra0.4

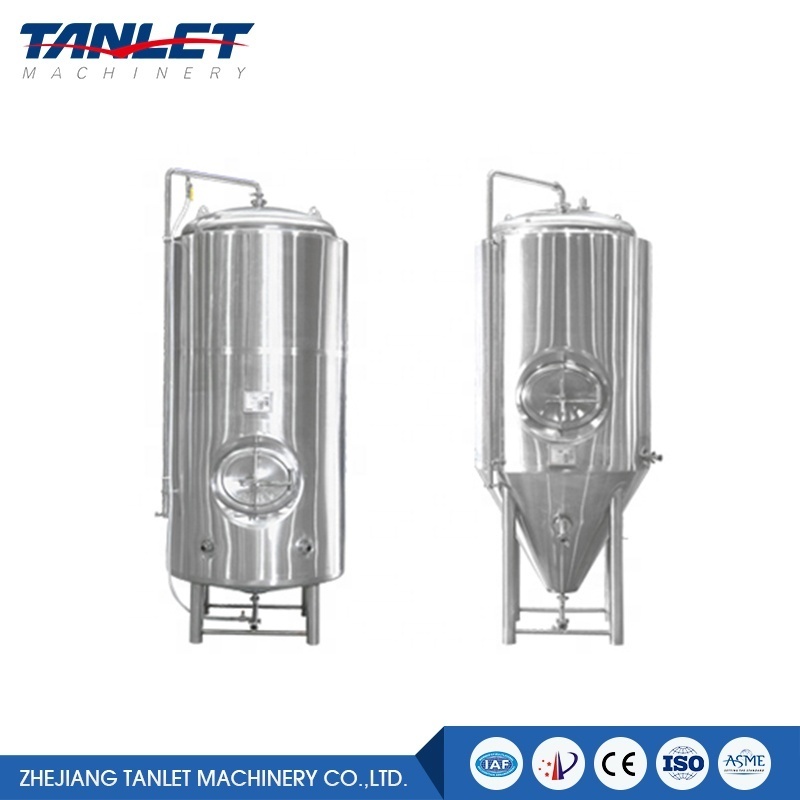

Stainless Steel Beer fermenter fermentation tank for Brewing System

1. Tank body system:

Tank body material: 316L or 304 stainless steel; tank body design pressure:0.3 Mpa ; jacket design pressure: 0.35Mpa;

Tank body structure: provided with special sampling valve and discharging valve for fermentation tank, as well as standard temperature, PH, and DO sensor vents

Tank cover structure: 1 standard foam pole socket, 1 view lamp and sight glass vent, 3 universal material adding vent, 1 inoculation vent, 1 air vent.

Surface treatment: stainless steel interior and exterior mirror polishing with polishing fineness of Ra0.4.

2. Sterilization: in-place steam sterilization;

3. Mixing System: special standard blade for fermentation with three-layer six flat vanes; control range: 50~300pm, control precision: ± 1%;

4. Temperature control: coding water temperature +5~6S°C; precision : ±0.10C;

5. pH control: Swiss Mettler pH pole and shielding conductor; range: 2~12pH, control precision: ±0.02pH;

6 .Oxygen dissolution control: Swiss Mettler DO pole and shieldin conductor; range: 5~100%, control precision: ±2%;

7. Foam control: automatic foam detection and defoamer adding; sensitivity 100~100000

8. Material adding control: peristaltic pump automatic adding; range: 0~5L/min, control precision: ±2%;

9. Air flow control: rotor flowmeter manual adjustment; range: 0~5000L/min.

Main Parameters

| Specification | 100L | 200L | 500L | 1m | 2m | 5m | 10m | 20m | 50m |

| Fermentation Tank Dia.(mm) | 400 | 500 | 700 | 900 | 1200 | 1500 | 1800 | 2300 | 3100 |

| Fermentation Height (mm) | 2000 | 2300 | 2650 | 2900 | 3800 | 4480 | 5250 | 6550 | 8550 |

| Inner Pressure (Mpa) | 0.2 | ||||||||

| Jacket Pressure (Mpa) | 0.3 | ||||||||

| Stirring Paddle | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 4 |

| Stirring Speed (r/m) | 400 | 360 | 265 | 220 | 180 | 160 | 145 | 125 | 110 |

| Motor Power (Kw) | 0.55 | 0.75 | 1.5 | 2.2 | 4 | 7.5 | 17 | 30 | 55 |

| Cooling Type | Jacket | Tubulation | |||||||

Jacket Type

Honeycomb Heat exchanging tubes Semi-tube jacket

Pcaking: Standard packing

Wooden case is avaliable for Stainless Steel Beer fermenter fermentation tank for Brewing System

Delivery: 1-45 days after the deposit confirmed

User demands analysis

Engineering design

Product manufacturing

Automatic control integration

Vertification service

Engineers are avaliable to go abroad to help installation.

Click here to see more products

Click here to learn more about us

Click here to contact us

======== ↓ ↓ ↓ keep moving down, more surprises await! ↓ ↓ ↓ ========