- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HW-300 PRO

-

Material:

-

/, ABS

-

Item Weight:

-

109

-

Accuracy:

-

/

-

Product name:

-

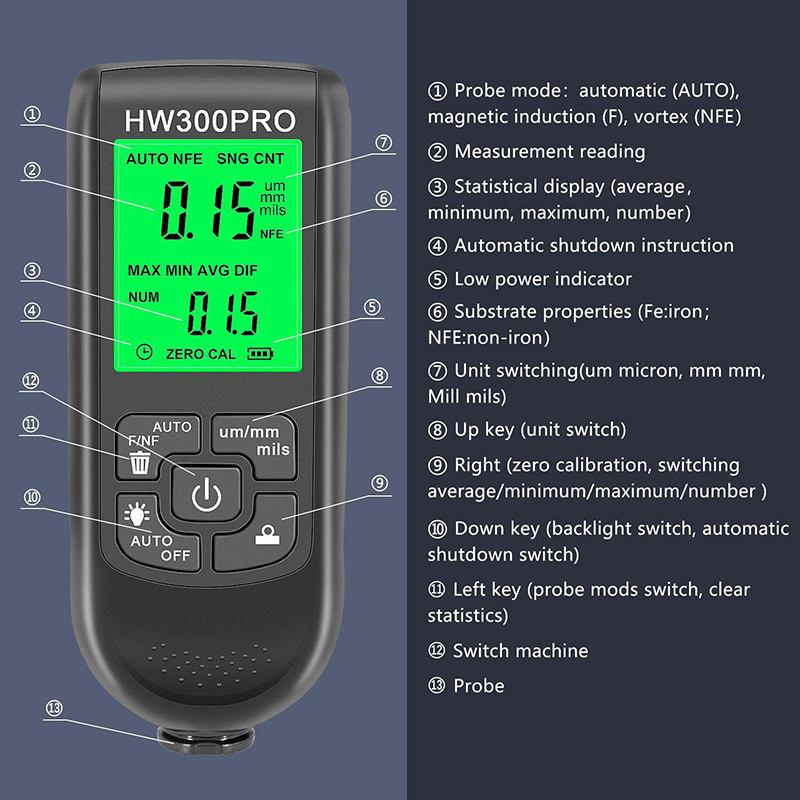

HW-300PRO Coating Thickness Gauge

-

Product size:

-

122*50*22(mm)

-

Power supply:

-

2*1.5V AAA batteries (battery not included)

-

Probe:

-

F probe, N probe

-

Magnetic induction:

-

Measuring principle(F), Eddy current effect(N)

-

Measuring range:

-

0-2000um

-

Measurement accuracy:

-

±(3% 1UM)

-

Operating temperature:

-

-10°C~50°C

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XEAST

-

Model Number:

-

HW-300 PRO

-

Material:

-

/, ABS

-

Item Weight:

-

109

-

Accuracy:

-

/

-

Product name:

-

HW-300PRO Coating Thickness Gauge

-

Product size:

-

122*50*22(mm)

-

Power supply:

-

2*1.5V AAA batteries (battery not included)

-

Probe:

-

F probe, N probe

-

Magnetic induction:

-

Measuring principle(F), Eddy current effect(N)

-

Measuring range:

-

0-2000um

-

Measurement accuracy:

-

±(3% 1UM)

-

Operating temperature:

-

-10°C~50°C

Product Description

Specifications:

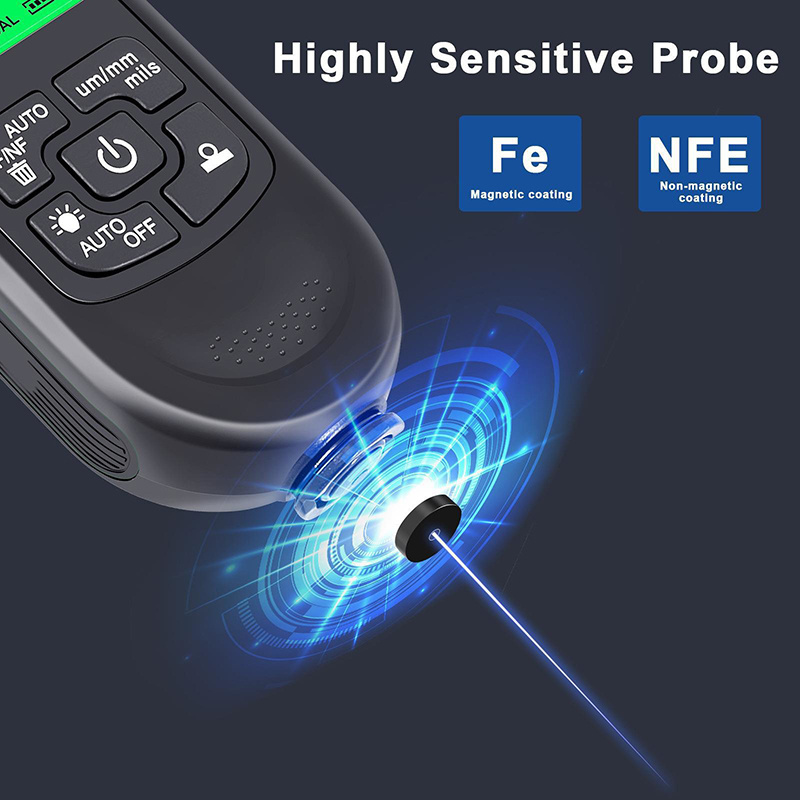

This product is mainly used to measure the thickness of non-conductive coating on metal surface, as well as the thickness of non-ferromagnetic coating on ferromagnetic metal (such as iron, nickel, cobalt, etc.), such as paint thickness on automobile surface, coating thickness of metal parts and so on. This product also has built-in magnetic induction and vortex double principle probe, can automatically identify the measured metal substrate, only need to be placed on the measured surface, can automatically calculate the thickness of the coating.

【1】The thickness gauge is used to measure the thickness of the plated and coated sheet on metal, e.g. paint/enamel/ chrome on steel, paint and anodizing coating on aluminum/copper.

【2】The measuring range is 0-2000UM.

【3】The gauge takes the precision integrated probe, and uses principles of electro-magnetic induction and the eddy current effect,

which automatically detects the attribute of substrates.

【4】The Gauge is designed for non-destructively measuring the thickness of coating and painting.

【5】It is essential for material surface treatment and widely used in manufacturing industry, metal-processing industry, chemical industry, commodity inspection area, and also able to work steadily in the laboratory, workshop and outdoor.

This product is mainly used to measure the thickness of non-conductive coating on metal surface, as well as the thickness of non-ferromagnetic coating on ferromagnetic metal (such as iron, nickel, cobalt, etc.), such as paint thickness on automobile surface, coating thickness of metal parts and so on. This product also has built-in magnetic induction and vortex double principle probe, can automatically identify the measured metal substrate, only need to be placed on the measured surface, can automatically calculate the thickness of the coating.

【1】The thickness gauge is used to measure the thickness of the plated and coated sheet on metal, e.g. paint/enamel/ chrome on steel, paint and anodizing coating on aluminum/copper.

【2】The measuring range is 0-2000UM.

【3】The gauge takes the precision integrated probe, and uses principles of electro-magnetic induction and the eddy current effect,

which automatically detects the attribute of substrates.

【4】The Gauge is designed for non-destructively measuring the thickness of coating and painting.

【5】It is essential for material surface treatment and widely used in manufacturing industry, metal-processing industry, chemical industry, commodity inspection area, and also able to work steadily in the laboratory, workshop and outdoor.

Measurement step:

Step 1. Prepare the parts to be tested.

Step 2. Stay away from the metal object at least 2 cm, press the switch key to turn on.

Note: it is suggested that the instrument should be zeroed with reference to "zero calibration" before testing.

Step 3. The probe is placed vertically and quickly on the surface to be measured until the drop is heard,and the measured value is displayed on the screen, and then the probe is lifted at least 2 cm away from the part to be measured, and the next measurement can be carried out.

Note: if the automatic shutdown function is turned on and there is no operation within 3 minutes, the instrument will automatically shut down

Step 1. Prepare the parts to be tested.

Step 2. Stay away from the metal object at least 2 cm, press the switch key to turn on.

Note: it is suggested that the instrument should be zeroed with reference to "zero calibration" before testing.

Step 3. The probe is placed vertically and quickly on the surface to be measured until the drop is heard,and the measured value is displayed on the screen, and then the probe is lifted at least 2 cm away from the part to be measured, and the next measurement can be carried out.

Note: if the automatic shutdown function is turned on and there is no operation within 3 minutes, the instrument will automatically shut down

Package Included:

1 x Thickness gauge

1 x Manual

7 x Calibration sheet

1 x Thickness gauge

1 x Manual

7 x Calibration sheet

Detailed Images

Hot Searches