- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

youna

-

Model Number:

-

Dye Ink

-

Product name:

-

Different color 36mm 32mm code printer black ink roller

-

Color:

-

black red white yellow blue green grey orange violet pink

-

Ink Type:

-

Environmental Eco Solvent Ink

-

Feature:

-

Vivid Color

-

Application:

-

Package Printing

-

Suitable Printer:

-

ink wheel printer

-

Packing:

-

Customized Packaging

-

Quality:

-

100% Testing

-

Warranty:

-

12 Months

-

Delivery:

-

Sea

Quick Details

-

Type:

-

solid ink

-

Printing Type:

-

Transfer Printing

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

youna

-

Model Number:

-

Dye Ink

-

Product name:

-

Different color 36mm 32mm code printer black ink roller

-

Color:

-

black red white yellow blue green grey orange violet pink

-

Ink Type:

-

Environmental Eco Solvent Ink

-

Feature:

-

Vivid Color

-

Application:

-

Package Printing

-

Suitable Printer:

-

ink wheel printer

-

Packing:

-

Customized Packaging

-

Quality:

-

100% Testing

-

Warranty:

-

12 Months

-

Delivery:

-

Sea

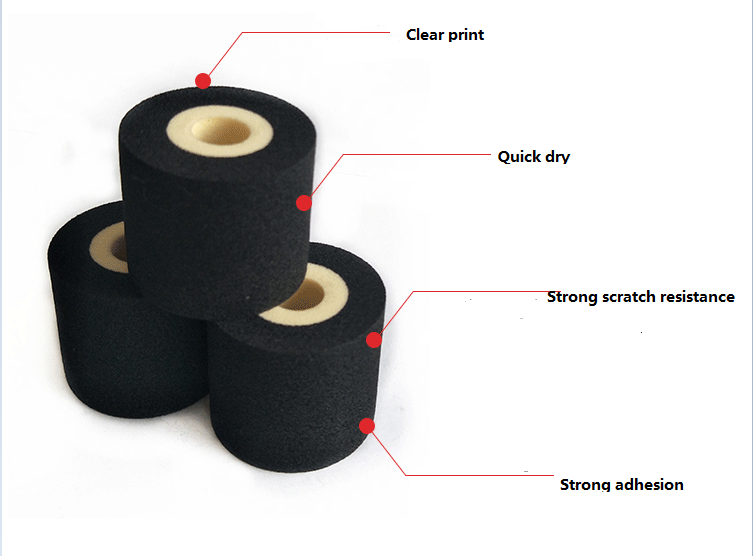

Black ink roller High Temperature Hot Solid Ink Roller for sealing Machine

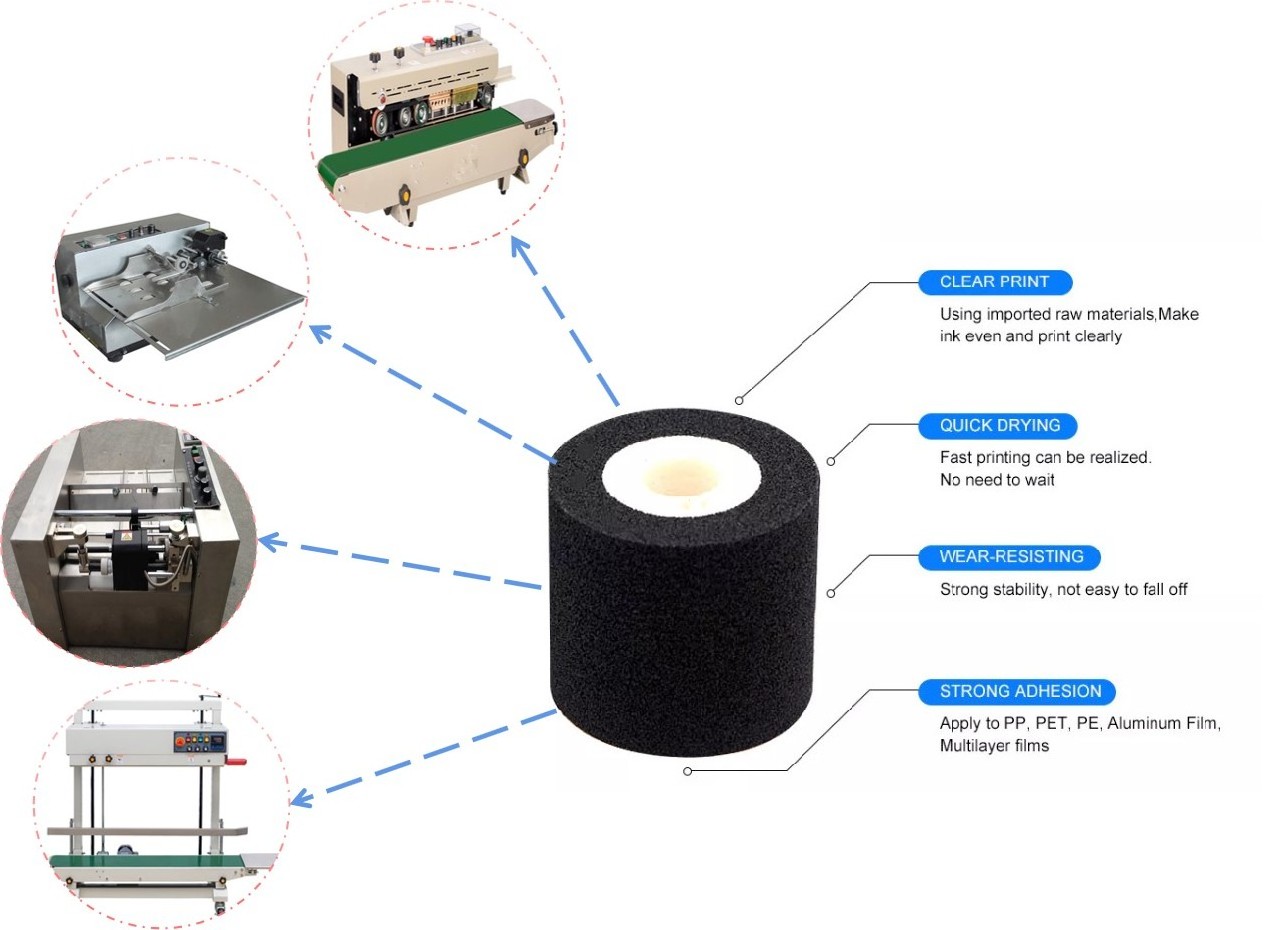

Product description: matching with ink wheel printer to print the production date, batch number and other related information on plastic film, paper and other materials, ink wheel has the characteristics of easy to use, non-toxic, can print quickly, instantly dry, clear, good adhesion, long service life.

The hot ink roll is used for ink roll coding machine, sealing machine, and 380F coding machine to print the production date, batch number and other digital and text identification on various

flexible packaging film such as paper, PP film, PE film, PVC ect. The ink roll is able to print at high speed, instant drying, good adhesion, anti friction, no pollution, and high resolution.

|

Model |

LH - 188 / LH - 6 |

LH - 189/LH-8 |

|

Service temperature |

90-130°C |

120-160°C |

|

Features |

easy to use, high definition, quick drying,anti-scratch,pollution-free , non-toxic, many times of printing, low cost, good adhesion. |

Strong adhesion, anti - freezing. |

|

Application |

Suitable for printing letters and numbers on flexible packaging materials such as paper, PP film, PE film, PET film, PVC etc. |

|

|

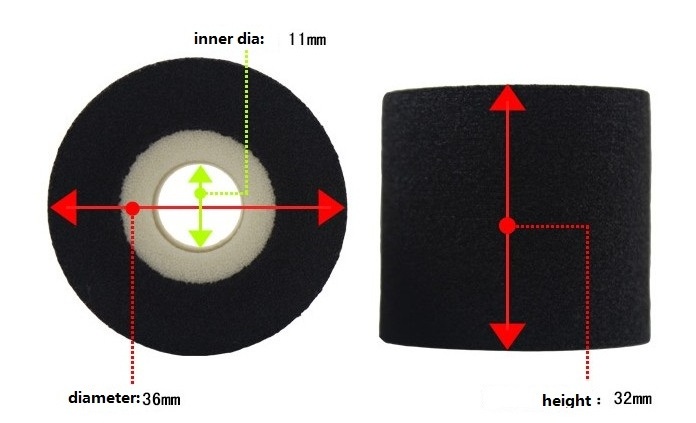

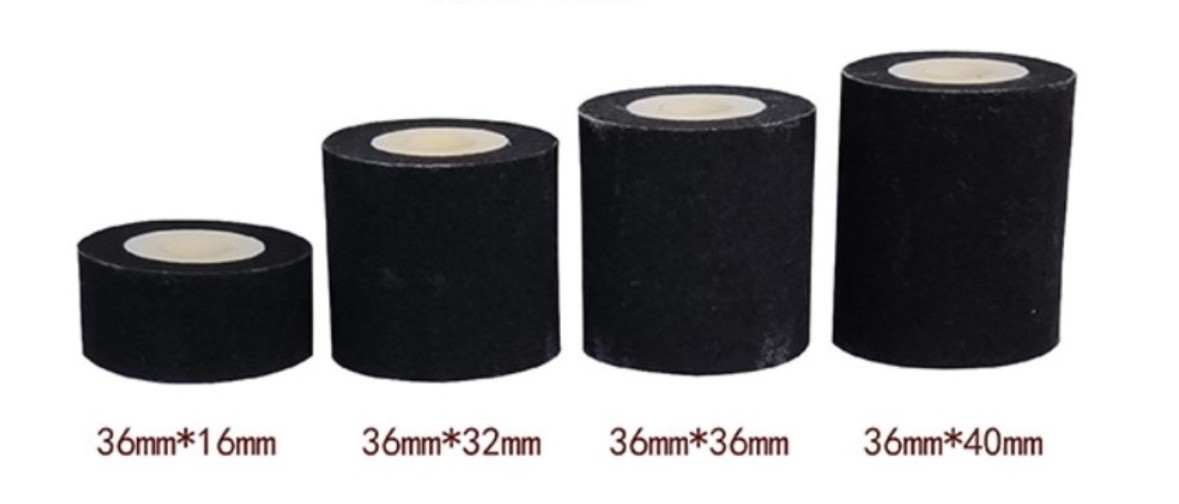

Specification |

36mm"10mm,36mm*16mm,36mm*32mm,36mm*36mm,36mm"40mm,40mm*40mm,48mm*55mm, 48mm*60mm, ect . |

|

|

Color |

black red white yellow blue green grey orange violet pink, |

|

|

Others |

Support to customize different colors and specifications |

|

How to use the ink roller

|

Fault |

Reason |

Resolution |

|

Can not print |

1.Pre-heat not enough, the temperature of ink roller and character wheel is too low. 2.Electric heat pipe or thermostat damage 3.The distance between character wheel and ink roller/support wheel not correct. |

1.Longer the pre-heat time 2.Replace the damaged parts 3.Adjust the distance between character wheel and ink roller/ support wheel. |

|

Printing not clear |

1.Temperature too low, ink roller isn’t full melting 2. lnk roller does not contact with character in place 3.Character inequality,badly abrasion 4.Ink roller dry and no ink 5.Support wheel not correct position 6.Character wheel not correct position 7.Character wheel/support wheel/shafts damaged |

1.Longer the pre-heat time increase the temperature. 2.The contact depth between the character and theinkrolleris0.5-2mm 3.Adjust or replace the characters. 4.Replace the ink roller 5The contact depth between the support wheel and theinkroleris0.1-0.3mm 6. Insert the Character wheel tight and fix it with the retaining ring 7.Check and replace the damaged parts. |

|

Ink roller scaling off |

Temperature too low the ink roller does not fully melt the characters damage it. |

Increase the pre-heating time and temperature, make the ink roller fully melt |

|

Printing too dark pollution |

1.Temperature too high e r Thermostat damaged 2.The contact depth between the character and the ink roller is too much. 3.The position of support wheel is too high. 4.Partial ink roller too hot 5.The character's surface blocked by ink 6.Too much ink accumulation in heating block. |

1.Lower the temperature or repla ce the Thermostat 2. The contact depth between character and theinkrolleris0.5-2r 3.The contact depth between t support wheel and the ink roller is 0 0.3mm 4.Idling the machine when pr heating. 5.Clean the characters 6.Clean the heating block |

|

Printing times too less |

1.The start temperature too high, the release of ink too fast 2.The temperature is not Increasing gradually Ink roller does not use up the ink |

1.Adjust the start temperature100℃(middle temp)120℃(high temp) ink accumulation, No ink flowing print clear 2.According to the instruction increase temperature gradually to reach the b printing effect. EG:Ink roller 36*32mm, before average weight 23g,after use avera ge weight 13g. The average inkoutpu8-12g |

More specification accept customization, pls contact freely