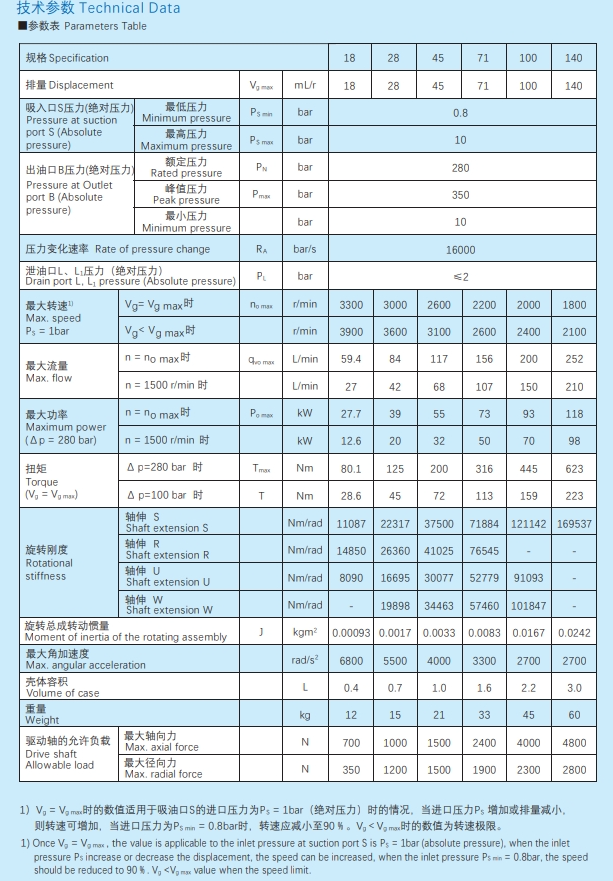

18/28/45/70/100/140ml

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Blince

-

Place of Origin:

-

Guangdong, China

-

Pressure:

-

Hydraulic Piston Bearing

-

Structure:

-

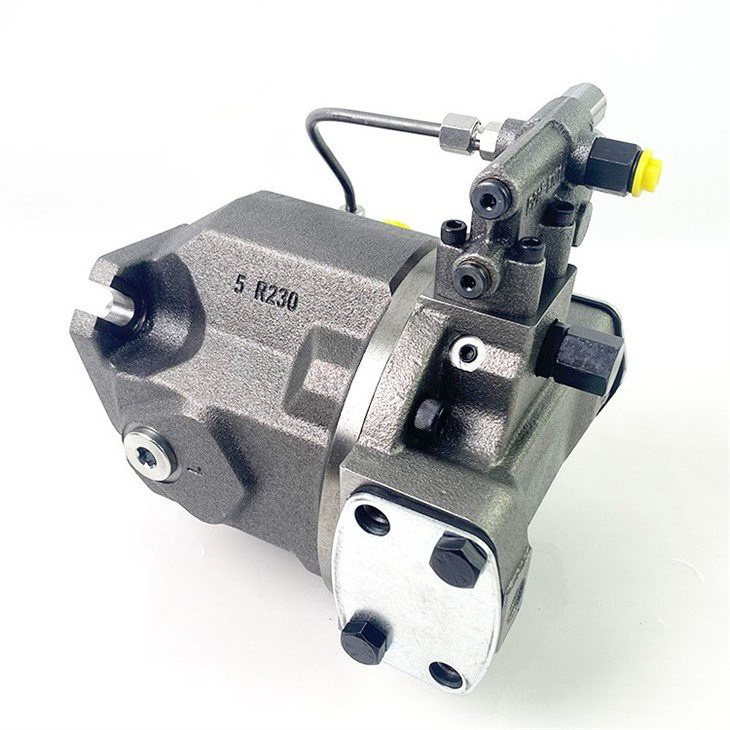

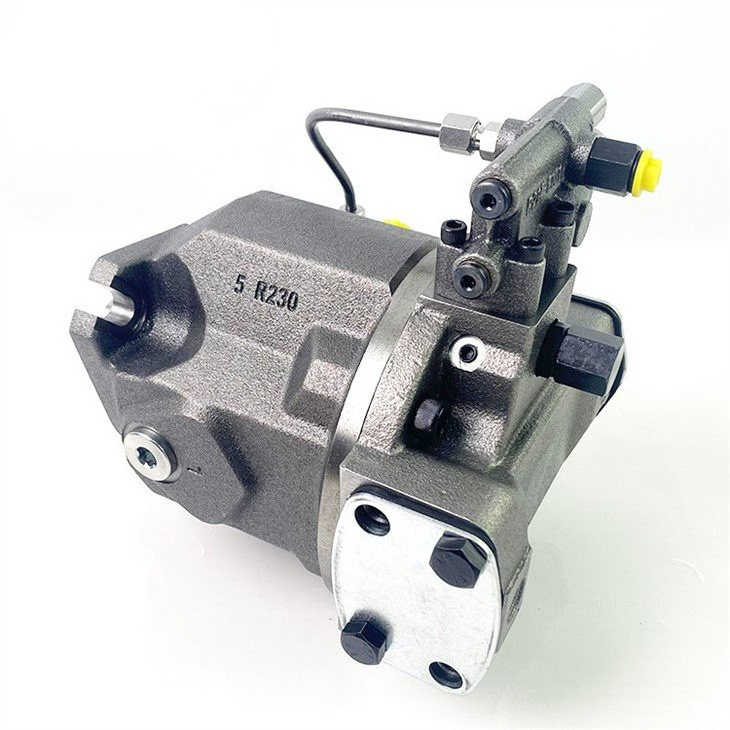

Axial piston pump

-

Weight:

-

48

-

Power:

-

27.7-118kw

-

Maximum Flow Rate:

-

252L/min

-

Product Type:

-

Hydraulic axial piston variable pumps

-

Model:

-

A10VSO18/28/45/71/100/140

-

Hydraulic fluid:

-

HM mineral oil

-

Flow Range:

-

59.4-252 L/min

-

Speed Range:

-

2100-3900 rpm

-

Features:

-

High pressure,heavy load

-

Application:

-

Engineering Machinery

-

Replacement:

-

100% replace Rexroth original

-

OEM:

-

Accept

Quick Details

-

Warranty:

-

1 Year

-

Displacement:

-

18-140ml/r, 18/28/45/71/100/140ml/r

-

Pump Type:

-

PISTON PUMP

-

Brand Name:

-

Blince

-

Place of Origin:

-

Guangdong, China

-

Pressure:

-

Hydraulic Piston Bearing

-

Structure:

-

Axial piston pump

-

Weight:

-

48

-

Power:

-

27.7-118kw

-

Maximum Flow Rate:

-

252L/min

-

Product Type:

-

Hydraulic axial piston variable pumps

-

Model:

-

A10VSO18/28/45/71/100/140

-

Hydraulic fluid:

-

HM mineral oil

-

Flow Range:

-

59.4-252 L/min

-

Speed Range:

-

2100-3900 rpm

-

Features:

-

High pressure,heavy load

-

Application:

-

Engineering Machinery

-

Replacement:

-

100% replace Rexroth original

-

OEM:

-

Accept

Product Description

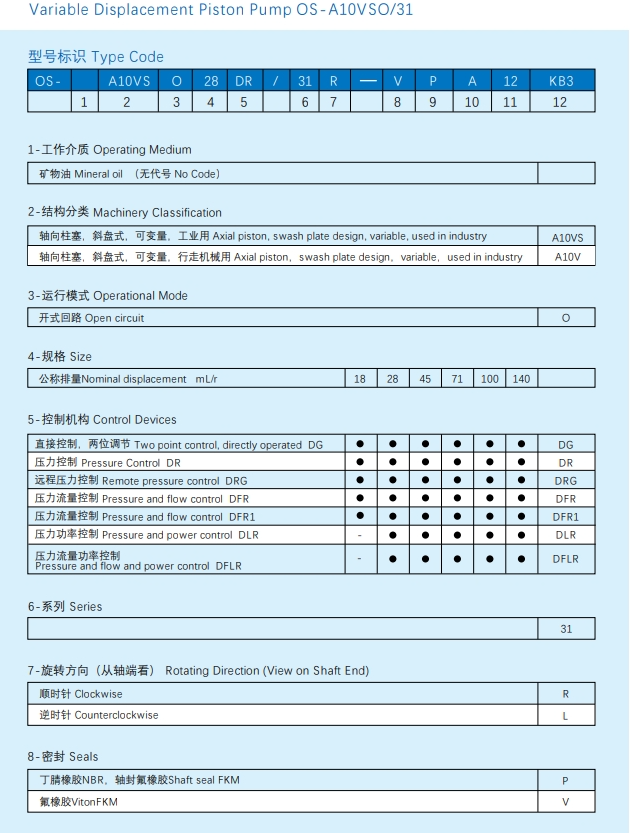

High-Pressure Variable Hydraulic Oil Pump Series A10VO45DFR/31R-VSC62N00 for High-Volta Applications

Displacement:

Features

A10V(S)O/31 series variable displacement piston pump swash plate axial plunger variable pump, respectively for industrial use and for mobile machinery design, is designed for open loop hydraulic driven design, adopts a shaft structure, rated working pressure up to 28Mpa.

Structural features:

※ The capacity of the pump is in proportion to its rotating speed and displacement; the stepless adjustment of the

displacement can be materialized by regulating the swivel angle of its swash plate.

※

There are many variable control forms, Fast control response;

※

Allows for continuous operating pressures up to 28MPa;

※

There are two shell discharge ports;

※

High power / weight ratio;

※

The drive shaft is able to bear the axial and radial load;

※

Wlth through-shaft structure, able to form combination pump;

1.Fluid

2.Axial piston unit

3.Operating mode

4.Size

5.Control device

6.Series

7.Direction of rotation

8.Seals

9.Shaft end

10.Mounting flange

11.Service ports

12.Through drive

13.Auxiliary pump mounted and piped to boost circuit filter

14.Valves

15.Filtration

2.Axial piston unit

3.Operating mode

4.Size

5.Control device

6.Series

7.Direction of rotation

8.Seals

9.Shaft end

10.Mounting flange

11.Service ports

12.Through drive

13.Auxiliary pump mounted and piped to boost circuit filter

14.Valves

15.Filtration

Summary of Controls

1.Manual control

MA

2.Electric motor control EM

3.Hydraulic control HD pilot pressure dependent

4.Hydraulic control HW path dependent

5.Hydraulic displacement control HM 1/2/3 control volume dependent

6.Hydraulic displacement control EO 1/2

7.Hydraulic displacement control HS,HS1,HS3 with servo or proportional valve

8.Speed control DS1 secondary controlled

9.Hydraulic control LR.N pilot pressure dependent initial position V

10.Pressure control DR

11.Pressure control for parallel operation DP

2.Electric motor control EM

3.Hydraulic control HD pilot pressure dependent

4.Hydraulic control HW path dependent

5.Hydraulic displacement control HM 1/2/3 control volume dependent

6.Hydraulic displacement control EO 1/2

7.Hydraulic displacement control HS,HS1,HS3 with servo or proportional valve

8.Speed control DS1 secondary controlled

9.Hydraulic control LR.N pilot pressure dependent initial position V

10.Pressure control DR

11.Pressure control for parallel operation DP

Applications

Hydraulic drive featured with high pressure, heavy load, variable, high displacement, long service time and reliable

● Steel metallurgy and forging machine tool

● Steel metallurgy and forging machine tool

● Ceramic and refractory material press

● Shipping and hydroelectricity

● Rubber

sulfurization and paper making

sulfurization and paper making

●Petroleum equipments

● Construction & walking machine

●Railway&shieldmachine

Quality Control

National Secondary Inspection

and Testing Center Qualification

Nationally recognized CNAS secondary testing center, imported high-precision testing instruments from Germany, the United States,Japan, etc., professional qualified testing personnel, QSmart quality control system.

The highest machining accuracy of the plunger ball head profile is

0.003mm,

and the testing accuracy of the measuring instrument is

0.0001mm.

Certificates

We have international and Chinese authoritative certification.

◆

Swiss SGS quality system certification

◆ International CE certification

◆ China Classification Society CCS Certification

◆ International CE certification

◆ China Classification Society CCS Certification

Company Profie

Blince

Dongguan Blince Machinery & Electronics Co., Ltd

was established in the year of 2004, which specializing in design, manufacture and sales of hydraulic components. Blince Hydraulics has become the leading manufacturer of hydraulic components, as well as a well known enterprise in the world.

Specializing in design, manufacturing and sales of hydraulic product include

hydraulic orbital motor

,

radial piston motor

,

hydraulic pump

,

hydraulic steering control unit

,

oil cooler,

hydraulic system

and more,

with over 15 years experience onproducts research and development.

Orbital motor from small OMM type to large torque OMS, OMT and OMV series. Vane pump include Yuken PV2R series, Vickers V/VQ series and Tokemic SQP series. Radial piston motor like NHM1 to NHM31.

We are located in Dongguan city which is an manufacturing city nearby Shenzhen port and Guangzhou port. It is very convenient for us to arrange shipment by sea.

For hydraulic equipment, please look for Blince !

For hydraulic equipment, please look for Blince !

Why Choose Us

BLINCE COMPANY ADVANTAGES

SINCE 2004

Blince Machinery & Electronics

Co., Ltd. specializes in the

business of hydraulic motor,

cycloid motor, vane pump and

hydraulic valve. Located in

Changan,Dongguan,

ADVANTAGE

Sourcing and managing different

kinds of goods originated from

plentiful factories and suppliers

around us, and you will always

find what you're looking for.

EXPERIENCED

We have already set up a team

with well-educated and

experienced staff members during

the past years. specializes in the

business of hydraulic motor,

cycloid motor, vane pump and

hydraulic valve

HYDRAULIC PUMP WORKSHOP

We are committed to developing high pressure axial piston pumps & motors and distributing hydraulic power units &system solutions

.

Ourteam of hydraulic experts and skilled technicians can help you get reliable,affordable,

competitiveand innovative hydrauli products and customized solutions for real world applications.

Capacity of manufacturing and testing

Passed ISO9001:2008 and CE certification,business standard conforming to DIN Germany for design, manufacturing, test and verifying. The quality control system covers the whole process of production.

OUR SERVICE & PACKING & SHIPPING & PAYMENT

Our High Quality Service

Pre-Sales Service

After-Sales Service

* Inquiry and consulting support. * Teach how to MOUNTING and USE the hydraulic motor.

* Sample testing support. * Arrange shipment 7-30days and update tracking No.

* View our Factory. * Warranty 1 year.

* Inquiry and consulting support. * Teach how to MOUNTING and USE the hydraulic motor.

* Sample testing support. * Arrange shipment 7-30days and update tracking No.

* View our Factory. * Warranty 1 year.

Payment Term

1,T/T, Paypal, Wester union and Alibaba Trade Assurance.

2. Delivery time: 7-15days after receiving deposite.

3. samples for quality reference are available.

4. Shipping port: Shenzhen/Guangzhou as your require.

2. Delivery time: 7-15days after receiving deposite.

3. samples for quality reference are available.

4. Shipping port: Shenzhen/Guangzhou as your require.

Packing & Delivery

Package

Size: 1.2 (L) *0.8(W) * 0.8 (D)

Packaging Details:

Packaging Details:

1. 30/50/100pcs wooden case

2. 100pcs plastic/wooden pallet.

3. 1 piece seperate weeden case.

2. 100pcs plastic/wooden pallet.

3. 1 piece seperate weeden case.

Delivery

1. MOQ is 1pc, price is more favorable for large quantity.

2. Leading time is within 3days if have inventory. If don't, within 30days if the quantity is less than 500pcs.

3. DHL, UPS, FEDEX, TNTetc, usually 5-7 days to arrive.

4. By sea/air, FOB/CIF trade etc, is normally 20-30days.

2. Leading time is within 3days if have inventory. If don't, within 30days if the quantity is less than 500pcs.

3. DHL, UPS, FEDEX, TNTetc, usually 5-7 days to arrive.

4. By sea/air, FOB/CIF trade etc, is normally 20-30days.

Hot Searches