- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

2400 - 4200 r.p.m

-

Place of Origin:

-

China

-

Weight (KG):

-

600 KG

-

item:

-

food grinder machine

-

Name:

-

Ultrafine Grinding Machine

-

Color:

-

Customer's Request

-

Product name:

-

Grinding Machine

-

Keyword:

-

sugar grinder machine sugar powder grinding machine

-

Function:

-

Pulverizer

-

Usage:

-

powder making machine

Quick Details

-

Output (kg/h):

-

20 - 1200 kg/h

-

Feeding Size (mm):

-

6 - 15 mm

-

Output Size (mesh):

-

12 - 120 mesh

-

Range of Spindle Speed(r.p.m):

-

2400 - 4200 r.p.m

-

Place of Origin:

-

China

-

Weight (KG):

-

600 KG

-

item:

-

food grinder machine

-

Name:

-

Ultrafine Grinding Machine

-

Color:

-

Customer's Request

-

Product name:

-

Grinding Machine

-

Keyword:

-

sugar grinder machine sugar powder grinding machine

-

Function:

-

Pulverizer

-

Usage:

-

powder making machine

Product Description

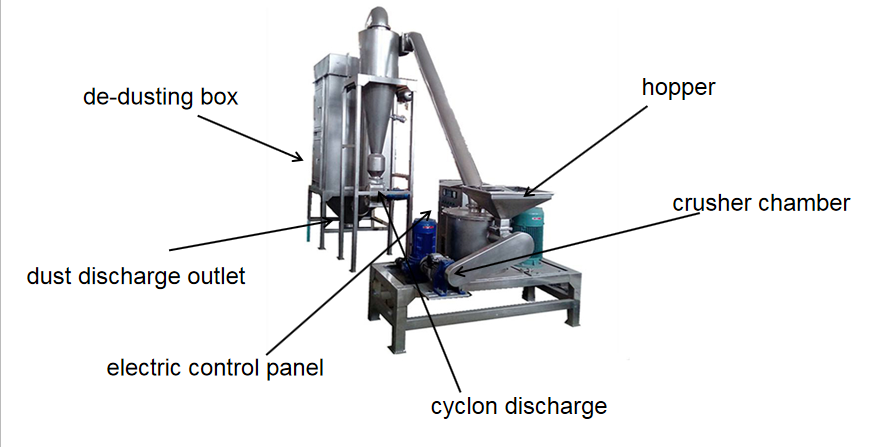

Working principle of

super fine pulverizer

The ultra-fine grinder is a vertical axis reflecting type grinder that can simultaneously complete two processing steps of fine grinding and fine separation. It consists of the machine body, machine frame, feeding device, crushing device, discharge pipe, transmission device and motor, and is composed of main machine, dust collector, high-pressure centrifugal fan, air lock, cyclone collector, electric control cabinet and complete air turbine micro powder unit. The granularity can be arbitrarily adjusted without stopping the machine. The product has a uniform particle size and a fineness of 80-320 mesh. The machine has a self-cooling function.

Application of

superfine pulverizer

Chemicals, traditional Chinese medicine, roots, stems, corn, rice, pepper, pepper, oil and wheat, soybean, soybean meal, garlic, star anise, cinnamon, dehydrated vegetables, hawthorn, dried ginger, garlic slices, sugar, saccharin, food, shrimp, pumpkin powder, seasoning.

|

Advantage of

superfine crusher

|

|

|

|

|

||||

|

1. GMP and food grade design pulverization.

|

|

|

|

|

||||

|

2. Negative pressure working condition can prevent dust and be suitable for heat sensitive material.

|

|

|

|

|

||||

|

3. Output size is adjustable via air classifier.

|

|

|

|

|

||||

|

4. Feeding rate is automatic controlled.

|

|

|

|

|

||||

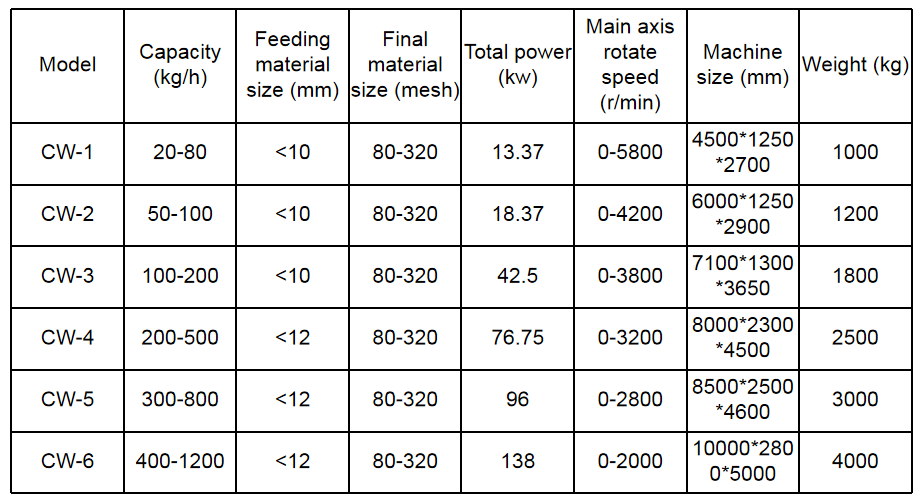

Size information

Notice before purchasing

Because of the different properties of materials, the following parameters are for reference only. Please consult our sales for specific models, and they will recommend the best model for you.

Detailed Images

Cutter head

When material come into the hopper, it will be slowly feed by the screw conveyor into the chamber. In the crushing chamber, you can see the classify wheel and the crushing plate. Both the crushing plate and classify wheel speed can be adjusted to control the final material mesh size. So this machine no need to use screen mesh set on the machine, and it can grind particles to 80-300 mesh based on your request.

Square type dust collector

Square type dust collector is much more easy to remove the bag filter and clean the inside of the machine. Also easy to install the bag filters inside. The filters are set line by line, so one solenoid valve can control one line filter. This makes the whole work flow working continuously. Fine powder material can be collected from the bottom of dust collector. The fan with noise reducer, can lower much noise on work site. Fan power can be customized based on different work site set situation.

Motor and hopper

With hopper inlet, the material feeding speed can be controlled by the valve at the inlet. Motor set on horizotal place with the crusher chamber will make the machine feeding height lower and easy to feed. This type is much more suit for line working and continuous working.

Control panel

Country of sale

Universal crusher

exported to India for processing

red chilli

High speed coarse crusher exported to Vietnam for processing black pepper

Air classifier mill

exported to France for cardamom processing

Universal

crusher

exported to Australia for cumin treatment

Customer site

, please refer to

Our Service

Packing & Delivery

Our Company

FAQ

Q:

How to get quotation quickly?

1. Grinding materials: Like chili, sugar, herbs...etc

2. Raw material size: Such as 10 mm,15 mm...etc

3..capacity: Like 50 kg/hr, 300 kg/hr,500 kg/hr..etc

4.Grinding fineness: mm mm (for example:0.8 mm)

5. Voltage:______V, Frequency:______HZ, phase

6. Contact material 304/SS304/316L stainless steel Q: What are your terms of payment? A: Our usual terms of payment are 50% t / T in advance and 50% t / T before shipment. Other ways can also be received after we have discussed and agreed.

Hot Searches