- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

50000 kg

-

Name:

-

4-roll Rubber Calender Machine

-

Application:

-

rubber factory, rubber sheet processing

-

Function:

-

Rubber sheet making

-

Roller Qty:

-

4

-

Core Components::

-

PLC, Engine, Bearing, Gearbox, Motor

-

Color:

-

costomized

-

Control system:

-

Automatic Control

-

Key selling point:

-

Energy saving

-

Running mode:

-

Automatic

-

Model:

-

XY-4F2130

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KUSK

-

Year:

-

order made

-

Weight (KG):

-

50000 kg

-

Name:

-

4-roll Rubber Calender Machine

-

Application:

-

rubber factory, rubber sheet processing

-

Function:

-

Rubber sheet making

-

Roller Qty:

-

4

-

Core Components::

-

PLC, Engine, Bearing, Gearbox, Motor

-

Color:

-

costomized

-

Control system:

-

Automatic Control

-

Key selling point:

-

Energy saving

-

Running mode:

-

Automatic

-

Model:

-

XY-4F2130

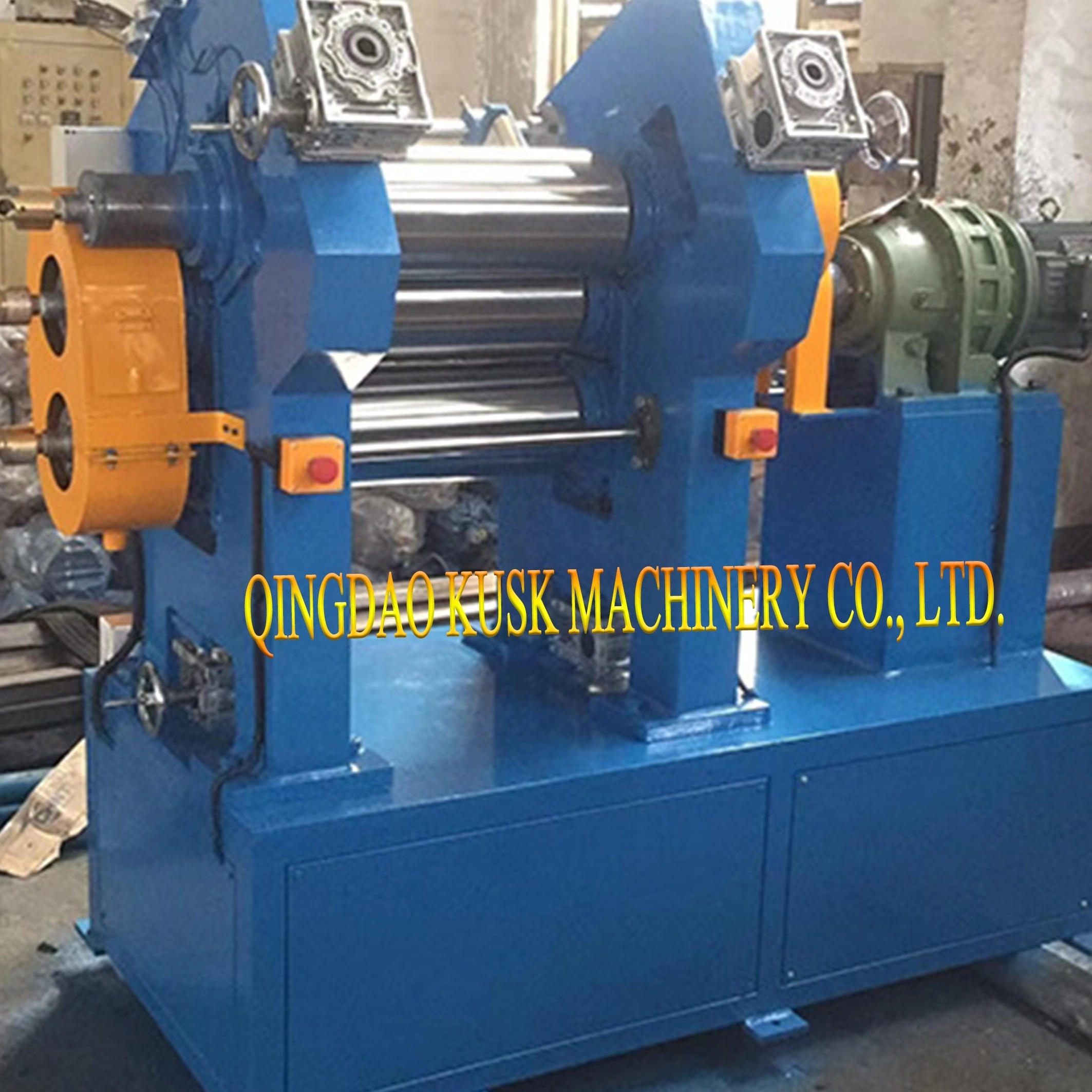

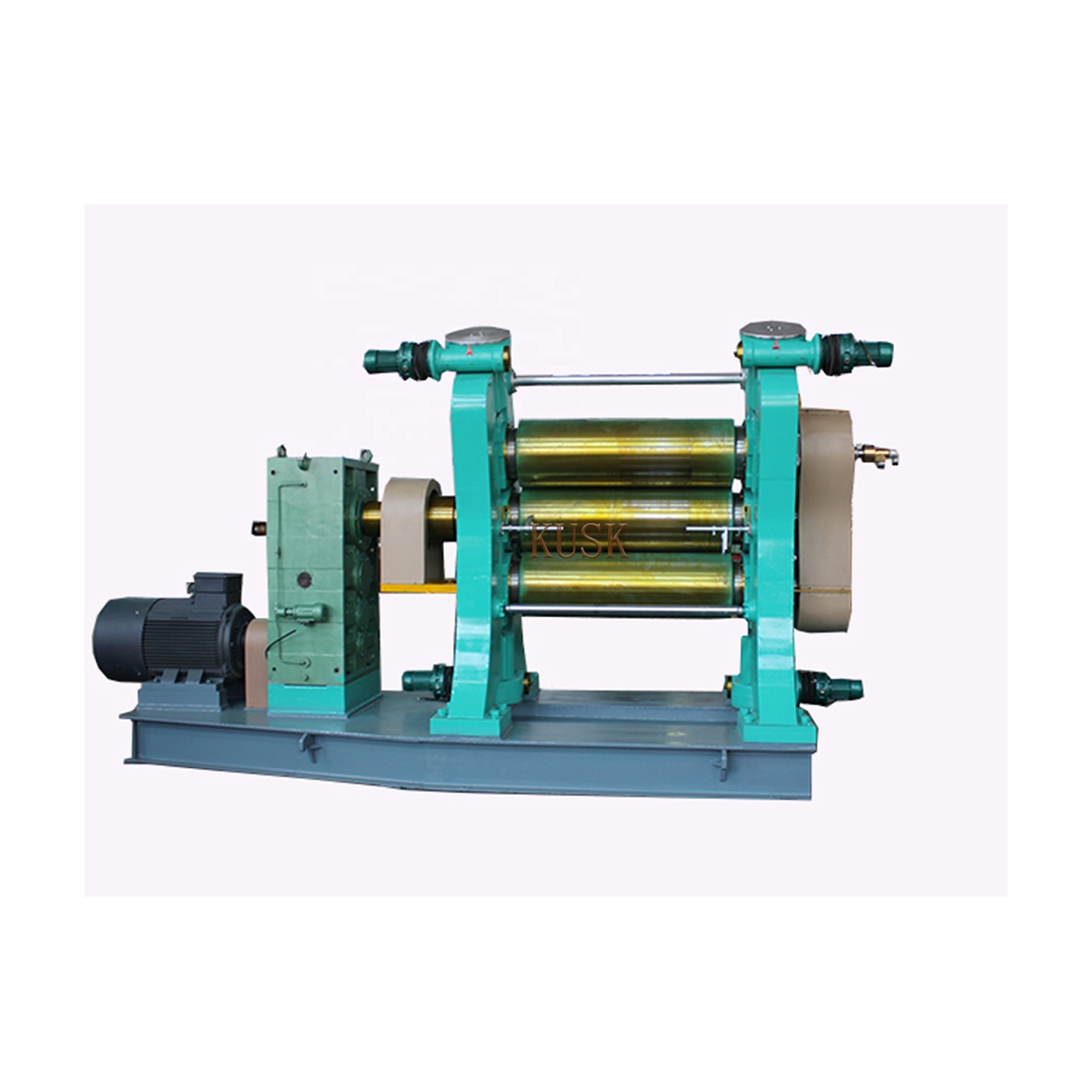

High Performance 2, 3, 4 Roll Rubber Calender/Calendering Roll Mill Machine

Features:

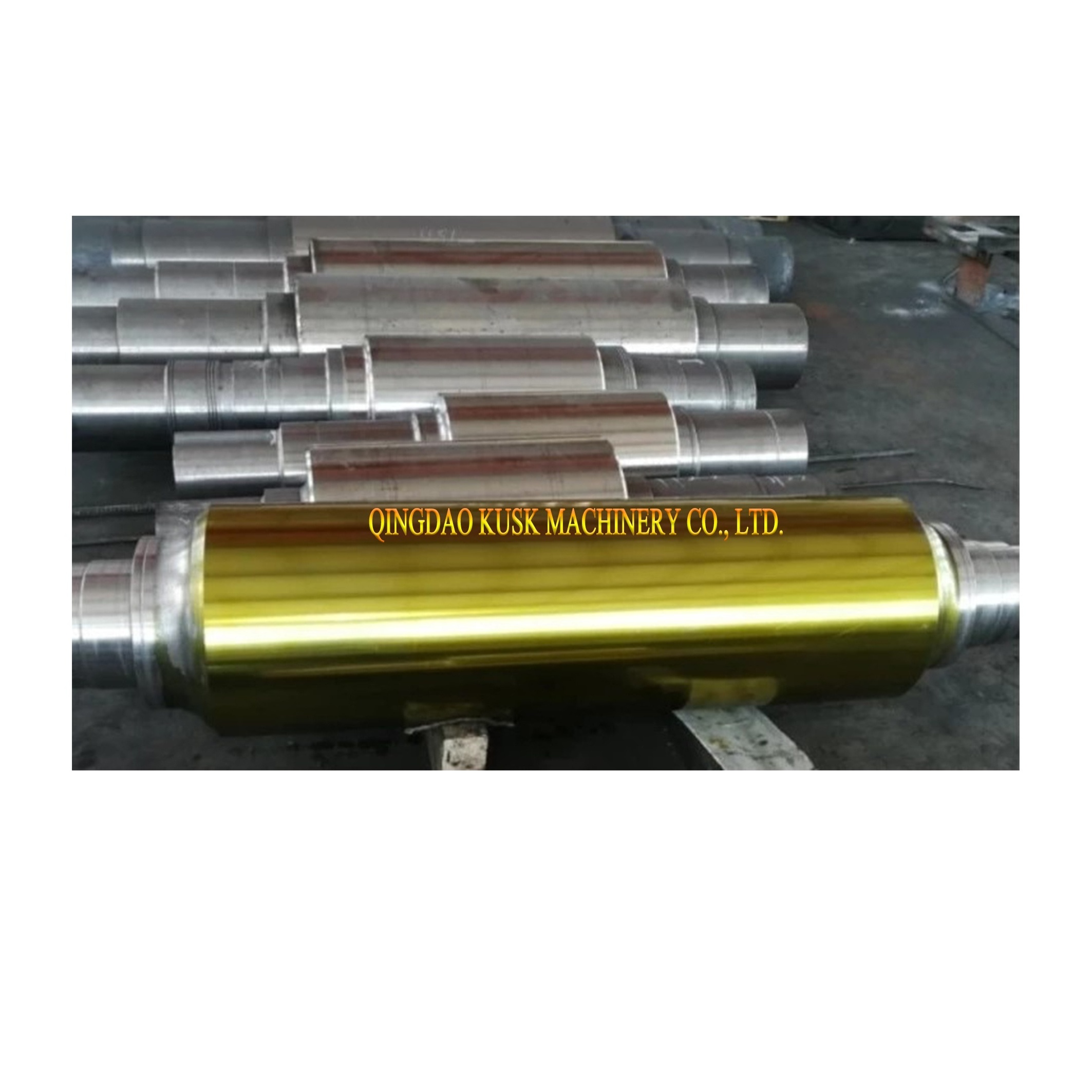

1. Rolls: chilled alloy cast iron rolls with surface hardness 68~72hs. the rolls are mirror finished &

polished, duly grinding and are hollowed for cooling or heating.

2. Roll clearance adjusting unit: nip adjustment at two roller ends is done manually using two separate

screws attached to the brass housing body.

3. Roll cooling: universal rotary joints with inner spray pipes with hoses and headers. piping is complete

up to supply pipe terminal.

4. Journal bearing housing: heavy duty steel casting housing fitted with anti friction roller bearings.

5. Lubrication: full automatic grease lubrication pump for anti friction roller bearings fitted in dust

sealed housing.

6. Stand frame & apron: heavy duty steel casting.

7. Gearbox: hard-tooth reduction gearbox, GUOMAO brand.

8. Base frame: common base frame heavy duty, steel channel and ms plate fabricated accurately

machined on which whole machine with gearbox and motor are fitted.

9. Electric panel: star delta electric operating panel with auto reversing, voltmeter, ampere, overload

protection relay, 3 phase indicator and emergency stop switch.

|

Model

|

XY-4

|

XY-4

|

XY-4

|

XY -4

|

XY-4

|

XY-4

|

||

|

Roller diameter |

mm |

230 |

360 |

400 |

450 |

610 |

710 |

|

|

Roller wording length |

mm |

630 |

1120 |

1400 |

1500 |

1730 |

2130 |

|

|

Roller ratio |

|

1:1:1:1 |

0.73:1:1:0.73 |

1:1.38:1.38:1 |

1:1.5:1.5:1 |

1:1.4:1.4:1

|

1:1.5:1.5:1 |

|

|

Middle -roll linear speed |

m/min |

2.1-21 |

2-20.1 |

3-26.3 |

2.5-25 |

8-50 |

3-30 |

|

|

Adjusting range |

mm |

0-10 |

0-10 |

0-10 |

0-6 |

20 |

0-20 |

|

|

Min.calendering product thickness |

mm |

0.2 |

0.2 |

0.2 |

0.2 |

0.15 |

0.15 |

|

|

Calendering product width |

mm |

500 |

920 |

1200 |

1250 |

1500 |

1900 |

|

|

Motor power |

kW |

15 |

55 |

75 |

110 |

160 |

185 |

|

|

|

L |

mm |

3800 |

3300 |

6600 |

6500 |

6580 |

7010 |

|

W |

mm |

930 |

940 |

1620 |

1970 |

2460 |

4150 |

|

|

H |

mm |

1890 |

2350 |

2490 |

2740 |

2920 |

3730 |

|

|

About weight |

tons |

~4.8 |

~14.6 |

~18.6 |

~33.5 |

~62 |

~100 |

|

...