- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

40-220bags/min

-

Weight (KG):

-

600

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SOULYAM

-

Dimension(L*W*H):

-

4100X950X1500mm

-

Product name:

-

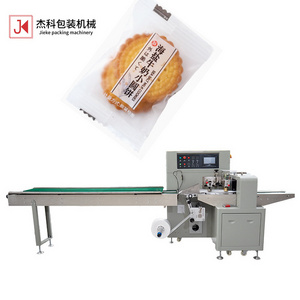

Milk Chocolate Wafer Energy Candy Bar Packing Machine

-

Packing speed:

-

40-220bags/min

-

Bag length:

-

No Limit

-

Packaging width:

-

30-110mm

-

Packaging height:

-

5-50mm

-

Date Printer:

-

Include

-

Control system:

-

3 Servo Control

-

Product Keywords:

-

Chocolate Bar Packing Machine

-

Product Keyword:

-

Energy Bar Packing Machine

-

Keyword:

-

Cookie Packing Machine

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Function:

-

FILLING, Wrapping, Capping, Sealing

-

Packaging Type:

-

Bags, Film, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

40-220bags/min

-

Weight (KG):

-

600

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SOULYAM

-

Dimension(L*W*H):

-

4100X950X1500mm

-

Product name:

-

Milk Chocolate Wafer Energy Candy Bar Packing Machine

-

Packing speed:

-

40-220bags/min

-

Bag length:

-

No Limit

-

Packaging width:

-

30-110mm

-

Packaging height:

-

5-50mm

-

Date Printer:

-

Include

-

Control system:

-

3 Servo Control

-

Product Keywords:

-

Chocolate Bar Packing Machine

-

Product Keyword:

-

Energy Bar Packing Machine

-

Keyword:

-

Cookie Packing Machine

-

Marketing Type:

-

Hot Product 2021

Specification

|

Model

|

KD-260

|

KD-350

|

KD-450

|

KD-590

|

KD-720

|

||||

|

Max Film Width

|

260mm

|

350mm

|

450mm

|

590mm

|

720mm

|

||||

|

Product Length

|

40-330mm

|

40-400mm

|

40-450mm

|

40-500mm

|

40-600mm

|

||||

|

Product Width

|

30-110mm

|

40-160mm

|

50-215mm

|

60-280mm

|

60-320mm

|

||||

|

Product Height

|

50mm

|

80mm

|

80mm

|

120mm

|

150mm

|

||||

|

Intensity of Seal

|

>15N/mm²

|

|

|

|

|

||||

|

Packing Speed

|

40-250 packages/minute

|

|

|

|

|

||||

|

Packing Material

|

BOPP/PE, CPP/PE, CPP/PA, BOPP, CPP Anti-Fog Film, OPP Film, Color Film, and so on.

|

|

|

|

|

||||

|

Thickness of Film

|

0.03-0.06mm

|

|

|

|

|

||||

|

Power

|

2.4KW 220V

|

2.4KW 220V

|

2.4KW 220V

|

2.8KW 220V

|

3.6KW 220V

|

||||

|

Overall Dimension

(mm)

|

4100x950x1500

|

4100x1000x1500

|

4100x1050x1500

|

5100x1050x1700

|

5100x1300x1700

|

||||

|

Weight

|

550KGS

|

600KGS

|

680KGS

|

800KGS

|

1000KGS

|

||||

Main Features

1). 3 Servo Motor control, flexible bag length cutting. Save time and film.

2). 7 inch touch screen, easy operation and multiple language for choice.

3). Smart PLC system, machine performance is stable, convenient for change parameter

4). Self diagnosis failure function, machine error can be clearly displayed in the touch screen.

5). Separate PID temperature controller, suitable for various packing materials

6). High sensitivity optical photocell for eye mark tracking, digital input for cutting position.

7). Position stop function, no adhesive and no waste of membrane and protect cutter.

8). Simple driving system, stable performance and convenient maintenance.

9). According to different product, the input conveyor can use pusher, belt or film for transportation.

10). High sensitive sensor to track the color mark, so the position of sealing and cutting will be more accuracy.

11).Automatic Detect the products, if no product feeding into the film, the machine will stop, no empty bag and no cutting the products.

12). No limit for product length

2). 7 inch touch screen, easy operation and multiple language for choice.

3). Smart PLC system, machine performance is stable, convenient for change parameter

4). Self diagnosis failure function, machine error can be clearly displayed in the touch screen.

5). Separate PID temperature controller, suitable for various packing materials

6). High sensitivity optical photocell for eye mark tracking, digital input for cutting position.

7). Position stop function, no adhesive and no waste of membrane and protect cutter.

8). Simple driving system, stable performance and convenient maintenance.

9). According to different product, the input conveyor can use pusher, belt or film for transportation.

10). High sensitive sensor to track the color mark, so the position of sealing and cutting will be more accuracy.

11).Automatic Detect the products, if no product feeding into the film, the machine will stop, no empty bag and no cutting the products.

12). No limit for product length

Product Description

Touch Screen

Easy Control Touch Screen , it can be set up the relevant language according to customer’s requirement. Simple page, easy operation, automatic fault diagnosis function, so the fault can be seen and understood more clearly, easier to maintenance. Memory function, save debugging time for packing different products and save the packing film.

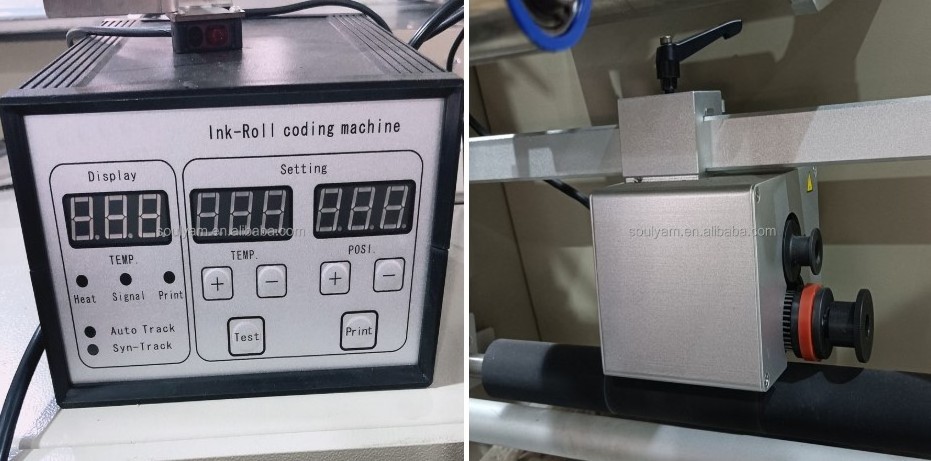

Ink Wheel Printer

It can printing production date and batch number

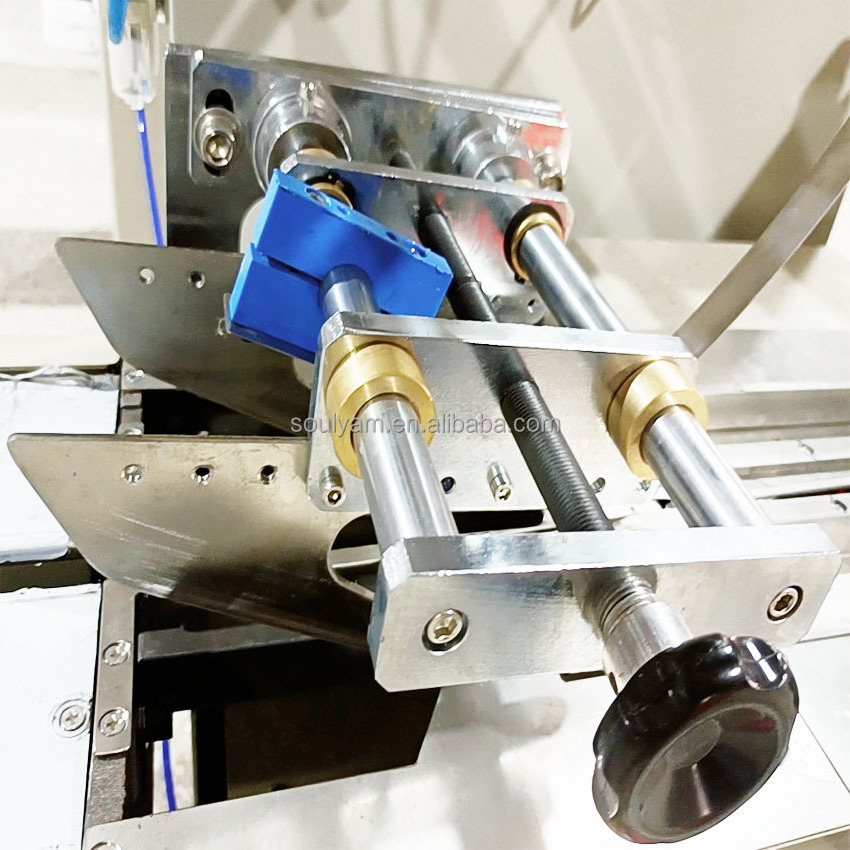

Bag Former

Adjustable bag former suitable for packing different width of products

Strong Film Roll Holder

It make sure the film feeding in steady, max diameter of film roll can be 35-45cm

Cursor Position Sensor

Cursor position Sensor Make sure bag forming more accurate

Verticle Back Sealing

Separate PID temperature controller, good sealing performance, suitable for various packing materials

Anti Empty Bag Sensor

Panasonic Sensor: Prevent Empty Bag Forming: No product feeding no bag forming. Save the packing films and production cost.

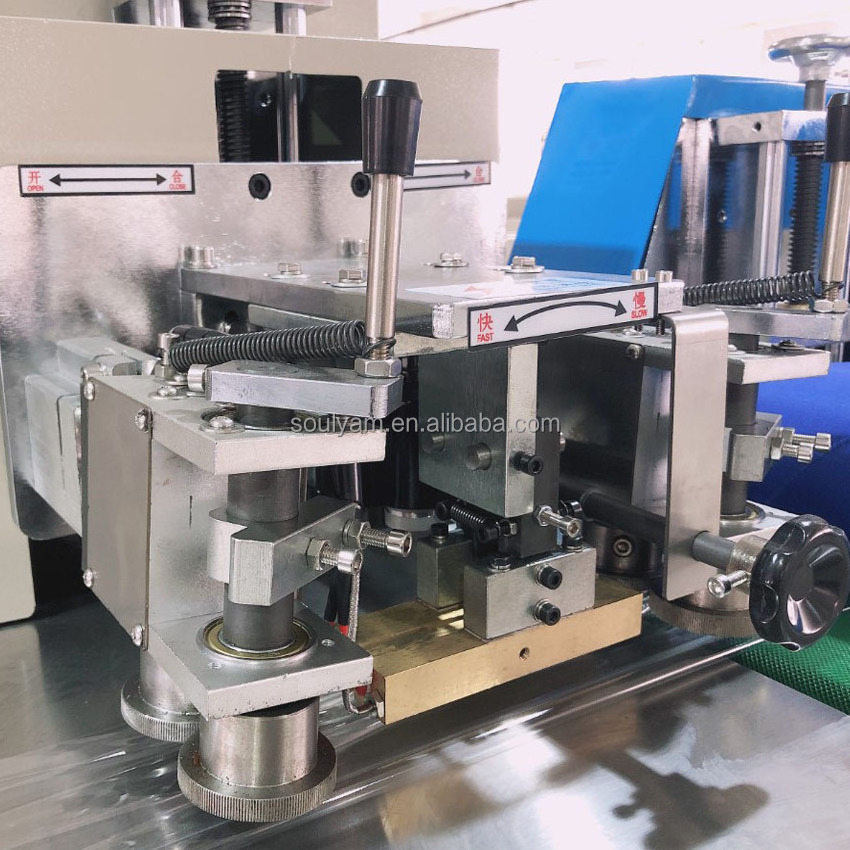

Horizontal Sealing Blade

Single/double/triple blade can be optional, Prevent cutting product, the Blade will reversing rotation and stop once its cutting the product

Exhaust Belt

It can packing flat products(face mask/rubber gloves) almost no air inside of bag

3 Servo Drive System

Compared with the general frequency conversion control model, reduces the adjustment of mechanical transmission parts, and improves the accuracy of the motion.

Strong Conveyor Structure

Good Quality Buttons,Easy connect with power.

Simple Driving System

Reliable working, convenient maintenance.

Nitrogen Filling Connector

Why filling Nitrogen: It can effectively prevent food oxidation, mildew, moth-eaten, corruption, can achieve

moisture-proof,quality preservation, preservation, prolong the storage period of food.

moisture-proof,quality preservation, preservation, prolong the storage period of food.

Production Machines In Bulk

Make sure we delivery plenty of machines to customers in time

Sample Display

Bag Type Display

Hot Searches