- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-25mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

Prima

-

Weight (KG):

-

4.5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training

-

Laser power:

-

500W / 1000W / 2000W / 3000W

-

Product name:

-

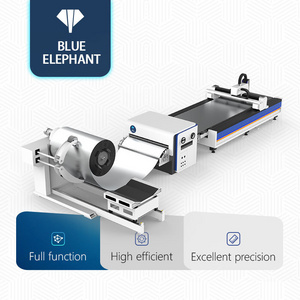

Coil Steel Fiber Laser

-

Name:

-

Coil Steel Fiber Laser

-

Keyword:

-

Metal Fiber Laser Cutting Machine

-

Type:

-

Rolled coil steel fiber laser cutting machine

-

Color:

-

Required

-

Laser tube:

-

BeiJing RECI

-

Function:

-

Cutting Metal Materials

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

15m/min

-

Cooling Mode:

-

Other

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-25mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

Prima

-

Weight (KG):

-

4.5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training

-

Laser power:

-

500W / 1000W / 2000W / 3000W

-

Product name:

-

Coil Steel Fiber Laser

-

Name:

-

Coil Steel Fiber Laser

-

Keyword:

-

Metal Fiber Laser Cutting Machine

-

Type:

-

Rolled coil steel fiber laser cutting machine

-

Color:

-

Required

-

Laser tube:

-

BeiJing RECI

-

Function:

-

Cutting Metal Materials

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

Single Table Rolled Coil Steel Fiber Laser Cutting Machine for Sheet Metal

Coil Fed Laser Cutting Machine Application:

Especially good for production of Filling Cabinet, Kitchen ware, Industry Cabinets, coach cabinet, vatilation system. And Processing, and material sheet thickness less than 2mm carbon steel, stainless steel, silicon steel and other metal roll materials. Rolled coil steel fiber laser cutting machine with auto feeding for galvanized

Technical Parameter

² Material Loading Weight: 5 tons and 10tons optional

² Decoiling System Parameter: Flatness Accuracy ±0.5mm

² Decoiling Sheet Thickness: ≤2mm or customerized

² Decoiling Width: 1300mm, 1500mm optional

² Feeding System Accuracy: ±0.2mm

Machine at customers' factories

The first coil fed laser cutting machine in China was developed and produced in 2015 by our factoru, so far we've produced more than 35sets for chinese local market and oversea market like Indonesia and Malaysia, fully meet the customers' requirents with advantage of saving labor cost, increasing production efficiency.

Worktable type:

- 1.Good Working stability, high frequency interfere effectively plasma, lightweight portable.

- 2.Support two cutting ways of flame and plasma.

- 3.Economic benefits, the structure and design is contracted. it adopts humanistic positive man-machine conversation and operate easil.

- 4.Cutting has high quality, high effect level, high precision.

- 5.Programmable cutting arbitrary shape parts of line and arc.

- 6.Dynamic and static graphic display, easy to learn. Can convert CAD file to program file in computer, through USB flash drive transmits to machine to realize cutting all kinds' graphs. And also can program and operate directly on the machine.

- 7.English and Chinese interface can free to convert.

- 8.Pre-sale will train and after-sale will track service. gantry cnc plasma/flame cutting machine for sale in alibaba china

We order the container to go our factory for the loading.

24 hours on line services, and we take care about the after-sales services.

Price : Give me reply, i will give you my favorable price immediately !

Payment term : 30% deposit and the balance paid against copy of B/L in 3 days .

Package : Standard exporting package .

Operation manual and video disc :

When delivery machine, the related operation instruction of model will delivery together with machine. And in the instruction, there is teaching video disc .

After-sales service :

1.machine is simple, generally, user can understand how to operate. There is operation instruction and disc .

2.welcome to our factory to learn how to operate our machine, we will give good training .

3.our engineer is available for user. If there is requirement, our engineer can go to user factory, and adjust machine, give good training to user .