- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongxing

-

Dimension(L*W*H):

-

2234*1370*1675--4622*3302*4470

-

Weight:

-

5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Small ballast stone crusher plant layout

-

Material:

-

Casting steel

-

Adaptability:

-

Strong

-

Factory:

-

50,000 square meters closed workshops

-

Technical service:

-

The whole using life

-

Running State:

-

Stable

Quick Details

-

Application:

-

mine,rock,marble

-

Capacity(t/h):

-

12-1000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongxing

-

Dimension(L*W*H):

-

2234*1370*1675--4622*3302*4470

-

Weight:

-

5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Small ballast stone crusher plant layout

-

Material:

-

Casting steel

-

Adaptability:

-

Strong

-

Factory:

-

50,000 square meters closed workshops

-

Technical service:

-

The whole using life

-

Running State:

-

Stable

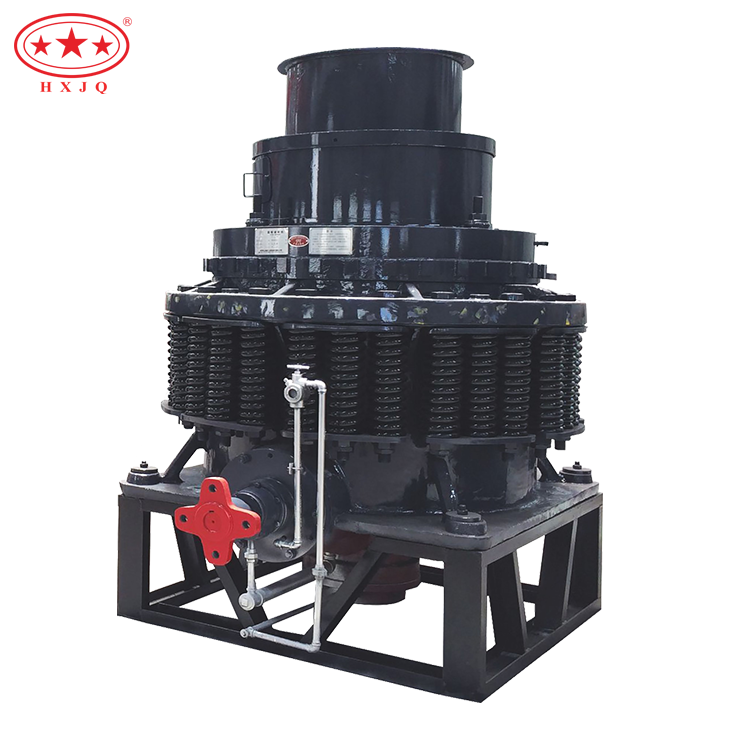

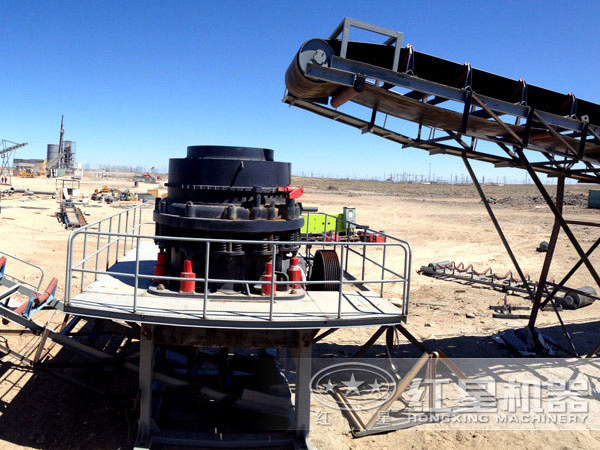

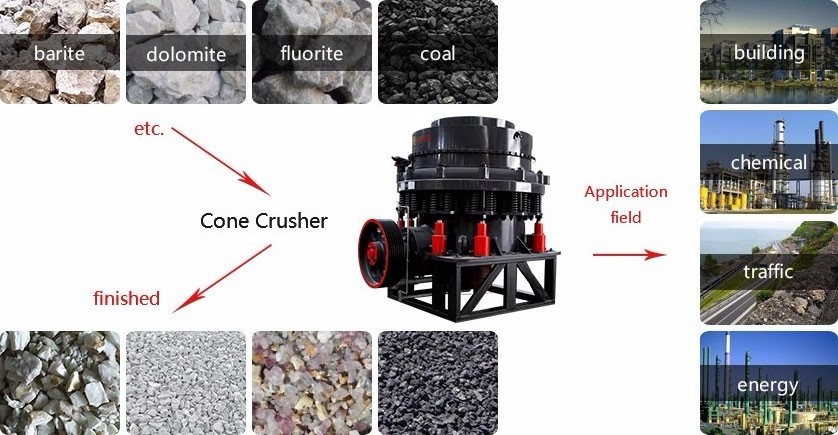

1.Introduction of Mining equipment stationary roller bearing aggregate stone spring cone crusher

• Mining equipment stationary roller bearing aggregate stone spring cone crusher is suitable for crushing various kinds of ores and rocks with medium over hardness. The spring safety system is the overload protection device which is able to make the iron go through the crushing chamber without damaging machine.

• It adopts two sealing means: dry oil and water to separate stone powders and lubrication grease, thus ensuring reliable work of the machine.

2.Types of Mining equipment stationary roller bearing aggregate stone spring cone crusher

♥ Mining equipment stationary roller bearing aggregate stone spring cone crusher is divided into three types, namely coarse cone crusher, medium cone crusher and fine cone crusher.

♥ The standard type is suitable for medium crushing; the medium type and the short-headed type is suitable for fine crushing, so that the customers can choose different types according specific need.

3.Working principle of Mining equipment stationary roller bearing aggregate stone spring cone crusher

When cone crusher begins to work, the electro motor drives the eccentric sleeve through the spring coupling, drive shaft and a pair of angle gear, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the rolling mortar wall fixed on the adjusting sleeve, and the ores inside the crushing chamber will be constantly impacted, squeezed and bent to be crushed.

Pre-service: Enthusiasm

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1.Select equipment model;

2.Design and manufacture products according to clients' special requirement;

3.Train technical personnel for clients.

Services during the sales: Servant

1.Pre-check and accept products ahead of delivery;

2.Help clients to draft solving plans.

After-sale services: Faithfulness

Provide considerate services to minimize clients' worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical exchanging.

7.Revisit regularly for establishing long-term and friendly relationship.

Service Commitment

Provide clients one-year warranty to make sure the machine work well.

Have spare parts of our very machine in stock all the time which means the replacements can bu sent to you timely.

Send every client a preferential quotation.

What about the quality of your products?

Our products are manufactured strictly in accordance with the national and international standard, and we always test every equipment before the delivery.We guarantee if the quality of products is different with the description we described before your placing order, we promise 100% refund.

Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

In order to help you get a suitable machine and provide you a preferential quotation,

Pls kindly provide the following information:

1. What's the materials to process?

2. What's the feature of the materials? Like density, moisture degree,input particle size and out put particle size.

3. What's your capacity per hour?

4. What's material for the machine?

5.What's the machine you want to buy?A single machine or a production line.