World famous brand electrical component: Siemens, Schneider, ABB etc;

High torque gearbox with adopts NSK/SKF bearing;

Siemens original motor achieved global after service;

Bimetallic screw and barrel;

Simple PID automatic temperature control system

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HUADE

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

18500*2330*2650

-

Weight:

-

8-20T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

Color:

-

Customized

-

Motor brand:

-

SIEMENS

-

Inverter:

-

ABB

-

Electric control:

-

Siemens PLC

-

Screw and barrel material:

-

38CrMoALA nitriding

-

Machine name:

-

PVC Wood Plastic Composite Production Line

-

Machine function:

-

WPC decking floor tiles extrusion machinery / WPC machine line

-

Automatic Grade:

-

Fully Automatic

-

Power:

-

185KW

-

Output (kg/h):

-

80 - 600 kg/h

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Double-screw

-

Screw Speed (rpm):

-

36 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HUADE

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

18500*2330*2650

-

Weight:

-

8-20T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

Color:

-

Customized

-

Motor brand:

-

SIEMENS

-

Inverter:

-

ABB

-

Electric control:

-

Siemens PLC

-

Screw and barrel material:

-

38CrMoALA nitriding

-

Machine name:

-

PVC Wood Plastic Composite Production Line

-

Machine function:

-

WPC decking floor tiles extrusion machinery / WPC machine line

-

Automatic Grade:

-

Fully Automatic

-

Power:

-

185KW

-

Output (kg/h):

-

80 - 600 kg/h

-

Certification:

-

CE ISO

Product Information

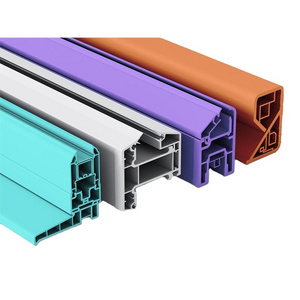

Plastic PVC (UPVC) /WPC (PE/PP+wood) Window Profile/Ceiling Panel/Door Board/Flooring Siding/Edge Banding/Corner Bead

Extrusion/Extruding Production Line

Extrusion/Extruding Production Line

PVC Imitation Marble Sheet Producing Machinery/Stone Profile Machinery

PVC Marble Profile Skirting and Siding Board Making Machine

Source Factory WPC Profile Production Line

Product information

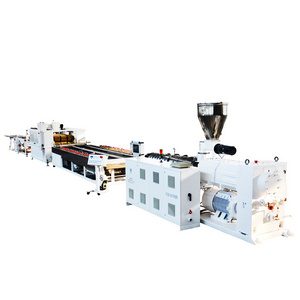

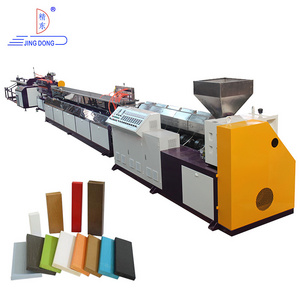

1,The whole line adopts intelligent control,high automation,stable

equipment,simple operation and high yield.

2,It is preferred domestic and abroad bamous brand screw,reducer,electric

appliance and motor to ensure the quality of the equipment.

3,This production line can change the molds to quickly produce 300-600mm

different size wallboard.

The working process of WPC decking extrusion line:

Raw material → feeder→ double screw extruder → mold → vacuum calibration table → cutting machine → stacker

1,The whole line adopts intelligent control,high automation,stable

equipment,simple operation and high yield.

appliance and motor to ensure the quality of the equipment.

different size wallboard.

The working process of WPC decking extrusion line:

Raw material → feeder→ double screw extruder → mold → vacuum calibration table → cutting machine → stacker

Details Images

Twin Screw Extruder

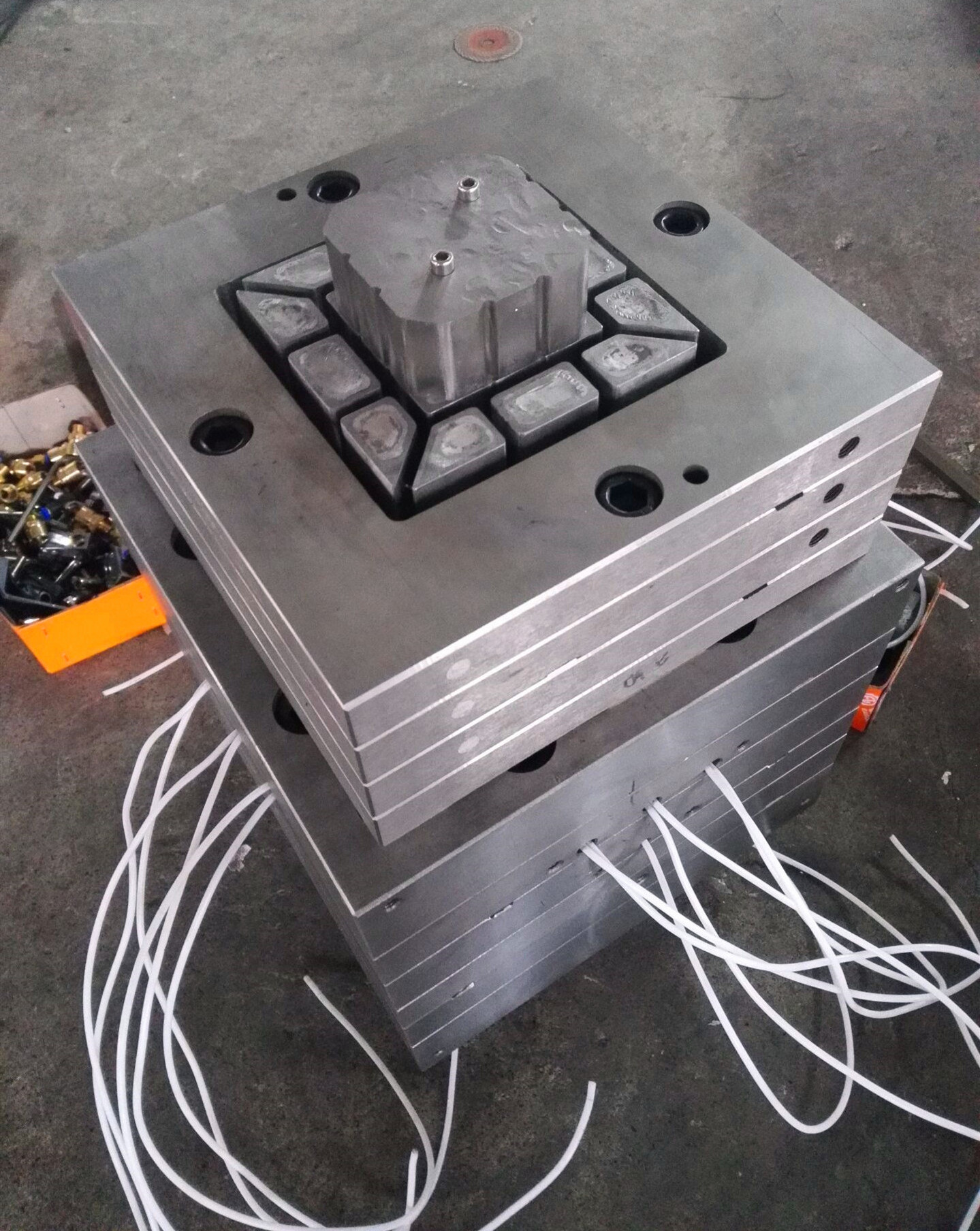

Die Head and Mould

Material 3Cr17, it includes the die head parts, vacuum calibrator parts, water cooling tank parts

Vacuum calibration table

Adopts powerful turbo cooling system, easy to achieve satisfactory cooling effect.

According to different moulds and different customer requirements, the vacuum calibrating table can be optional as 4m or 6m.

According to different moulds and different customer requirements, the vacuum calibrating table can be optional as 4m or 6m.

Saw Cutter

Smooth cutting with dust collector

Stacker

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Surface treatment device (sanding machine )

Surface treatment device (sanding machine )

Specification

|

Product Width

|

180mm

|

250mm

|

300mm

|

600mm

|

|

Extruder Model

|

SJZ55/110

|

SJZ65/132

|

SJZ65/132

|

SJZ80/156

|

|

Main Motor Power

|

22KW

|

37KW

|

37KW

|

55KW

|

|

Capacity

|

100Kg/h

|

120Kg/h

|

150Kg/h

|

250Kg/h

|

Hot Searches