- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

mixed

-

Place of Origin:

-

China

-

Brand Name:

-

PU31

-

Model Number:

-

PU31

-

Type:

-

Polyurethane Adhesive For Laminating

-

Curing system:

-

Room temperature curing

-

Application:

-

sandwich panels with skin materials

-

Color:

-

Brownish yellow liquid

-

Component:

-

One Compoent Polyurethane Sealant

-

Advantage:

-

High expansivity, high strength, good filling and leveling.

-

Package:

-

20kg/ Bucket, 200kg/ Drum, 1100kg/IBC.

-

OEM:

-

Acceptaple

-

Solid content:

-

100%

-

Shelf life:

-

6 months

-

Viscosity:

-

2500±500 mPa.s

Quick Details

-

CAS No.:

-

mixed

-

Other Names:

-

sandwich panel pu adhesive

-

MF:

-

mixed

-

EINECS No.:

-

mixed

-

Place of Origin:

-

China

-

Brand Name:

-

PU31

-

Model Number:

-

PU31

-

Type:

-

Polyurethane Adhesive For Laminating

-

Curing system:

-

Room temperature curing

-

Application:

-

sandwich panels with skin materials

-

Color:

-

Brownish yellow liquid

-

Component:

-

One Compoent Polyurethane Sealant

-

Advantage:

-

High expansivity, high strength, good filling and leveling.

-

Package:

-

20kg/ Bucket, 200kg/ Drum, 1100kg/IBC.

-

OEM:

-

Acceptaple

-

Solid content:

-

100%

-

Shelf life:

-

6 months

-

Viscosity:

-

2500±500 mPa.s

Product Description

PU

31 is a foaming, moisture curing, one-component polyurethane adhesive for bonding sandwich panels and similar constructions of various materials. In the process of curing, it will foam and expand to make the uneven surface level.

Typical Applications

It is used primarily for bonding sandwich panels with skin materials of pre-treated or primed aluminum, steel, glass fiber

reinforced plastic and core materials of plywood, wood, extruded / expanded polystyrene and mineral wool.

This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be

performed, ensuring adhesion and material compatibility.

reinforced plastic and core materials of plywood, wood, extruded / expanded polystyrene and mineral wool.

This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be

performed, ensuring adhesion and material compatibility.

Key features

1. Solvent free.

2. Room temperature curing

3. High expansivity,high strength and good filling and leveling to bonded substrate;

4. Easy to use, pumpable, and less consumption.

2. Room temperature curing

3. High expansivity,high strength and good filling and leveling to bonded substrate;

4. Easy to use, pumpable, and less consumption.

Specification

|

PROPERTY

|

STANDARD

|

UNITS

|

VALUE

|

|

Appearance

|

Visual

|

Visual

|

Brownish yellow liquid

|

|

Cure mechanism

|

Moisture

|

Moisture

|

Moisture curing

|

|

Density (uncured)

|

GB/T 13354-92

|

g/cm^3

|

1.1

|

|

Viscosity

|

GB/T 10247-2008

|

mPa.s

|

2500±500

|

|

Solid content

|

100%

|

%

|

100

|

|

Open time

|

GB/T 10247-2008

|

min

|

20

|

|

Curing time

|

GB/T 10247-2008

|

min

|

45

|

|

Application temperature

|

GB/T 20028-2005

|

℃

|

15-30

|

|

Tensile shear strength

|

Aluminum – aluminum(Mpa)

|

Aluminum – aluminum(Mpa)

|

>2

|

|

Shelf life

|

Month

|

Month

|

6

|

Directions for Use

* Before use

This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be

performed, ensuring adhesion and material compatibility.

please be sure to read the material safety data sheet to understand the corresponding preventive measures and safety suggestions.In addition, for chemical products that are exempt from mandatory labeling, relevant precautions should always be observed.

* Surface preparation

Surfaces must be clean, dry and free from grease, oil, dust and contaminants. After the cleaning process, a physical or chemicalpre-treatment might be required, depending on surface and type of material. The type of pre-treatment must be determined by tests.

During the curing process, carbon dioxide is released from the adhesive. If none of the substrates are porous, measures need to be taken to allow the carbon dioxide to escape.

* Application

Typically a coat weight between 100 and 300 g/m2 is applied, depending on the substrates to be bonded. The specific coat weight for a given substrate combination must be determined by tests.

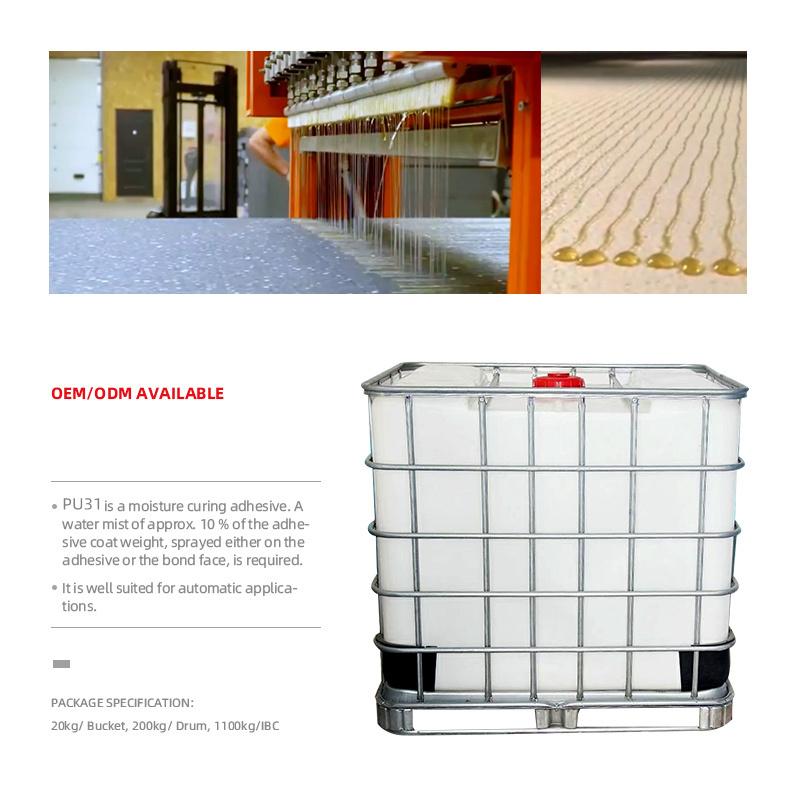

It is a moisture curing adhesive. A water mist of approx. 10 % of the adhesive coat weight, sprayed either on the adhesive or the bond face, is required. It is well suited for automatic applications.

For manual application, apply with trowel, spray water mist on the surface and press parts together before the end of the open time.

An adequate bonding pressure is necessary to obtain a voidless contact between the substrates and the adhesive.

* Before use

This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be

performed, ensuring adhesion and material compatibility.

please be sure to read the material safety data sheet to understand the corresponding preventive measures and safety suggestions.In addition, for chemical products that are exempt from mandatory labeling, relevant precautions should always be observed.

* Surface preparation

Surfaces must be clean, dry and free from grease, oil, dust and contaminants. After the cleaning process, a physical or chemicalpre-treatment might be required, depending on surface and type of material. The type of pre-treatment must be determined by tests.

During the curing process, carbon dioxide is released from the adhesive. If none of the substrates are porous, measures need to be taken to allow the carbon dioxide to escape.

* Application

Typically a coat weight between 100 and 300 g/m2 is applied, depending on the substrates to be bonded. The specific coat weight for a given substrate combination must be determined by tests.

It is a moisture curing adhesive. A water mist of approx. 10 % of the adhesive coat weight, sprayed either on the adhesive or the bond face, is required. It is well suited for automatic applications.

For manual application, apply with trowel, spray water mist on the surface and press parts together before the end of the open time.

An adequate bonding pressure is necessary to obtain a voidless contact between the substrates and the adhesive.

The specific pressure is, however, dependent on the core material and must be determined by tests.

The pressure must always be below the maximum compressive strength of the core. After starting the press process, do not release the pressure until the press time has elapsed.

* Curing

The mixture can be cured between 15 ℃ -30 ℃. The higher the temperature, the faster the curing speed. The lower the temperature, the slower the curing speed.

During the curing process, carbon dioxide is released from the adhesive. If no substrate is porous, measures need to be taken to allow carbon dioxide to escape (for example, cavities in the bonding surface).

* Curing

The mixture can be cured between 15 ℃ -30 ℃. The higher the temperature, the faster the curing speed. The lower the temperature, the slower the curing speed.

During the curing process, carbon dioxide is released from the adhesive. If no substrate is porous, measures need to be taken to allow carbon dioxide to escape (for example, cavities in the bonding surface).

Packing & Delivery

Package specification:

20kg/ Bucket, 200kg/ Drum, 1100kg/IBC.

The products are tightly packed in iron drums, and the color and weight are marked on the certificate of conformity.

20kg/ Bucket, 200kg/ Drum, 1100kg/IBC.

The products are tightly packed in iron drums, and the color and weight are marked on the certificate of conformity.

Hot Searches