- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Depends on the actual situation

-

Material:

-

Boiler Steel

-

Rated working pressure:

-

0

-

Color:

-

Color Optional

-

Thermal efficiency:

-

98%

-

Rated Outlet water Temp.:

-

85

-

Rated Return water temp.:

-

65

-

Voltage:

-

220v/380v

-

Other Boilers:

-

Biomass steam boiler

-

Outlet vavle:

-

DN150

-

Operation:

-

Automatic control

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinda Boiler

-

Dimension(L*W*H):

-

Depends on the actual situation

-

Weight:

-

Depends on the actual situation

-

Material:

-

Boiler Steel

-

Rated working pressure:

-

0

-

Color:

-

Color Optional

-

Thermal efficiency:

-

98%

-

Rated Outlet water Temp.:

-

85

-

Rated Return water temp.:

-

65

-

Voltage:

-

220v/380v

-

Other Boilers:

-

Biomass steam boiler

-

Outlet vavle:

-

DN150

-

Operation:

-

Automatic control

Product Description

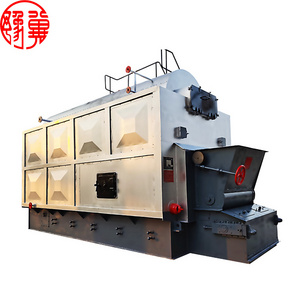

100 kw 600kw Solid Fuel Olive Husk Pellets Biomass Coal Fired Hot Water Boiler for Greenhouse Heating System

Biomass hot water boiler is a best option to villas, hotels, hospitals, factories, restaurants, schools, sauna center, beauty salon, swimming pool, greenhouse, food factories, laundries, industrial hot water, central air condition and heating spaces. Mainly used in home and industrial to support hot water and other heating system. With the advantage of high acceptance by operators , environmental friendly ,low operating cost, simple operation and maintenance , saving 30 to 60% of fuel costs than the traditional fuels Oil/Gas/Electricity boilers.

Advantages of biomass hot water boilers:

1. High efficiency

Using positive pressure combustion, the combustion efficiency is greatly improved.

2. Environmental protection

The size of the furnace is matched with the combustion flame, and the thermal efficiency is high.

3. Safety

The furnace adopts double densely arranged coils, and the heating surface is fully arranged, which reduces the heat load on the surface of the tube and makes the use of heat transfer oil safer.

4. Small footprint:

Boiler has a compact structure, which greatly saves the floor space of the boiler room.

Technical Parameter

|

Type

|

CLHS0.12

|

CLHS0.24

|

CLHS0.35

|

CLHS0.48

|

CLHS0.7

|

CWNS1.05

|

CWNS1.4

|

CWNS2.1

|

CWNS2.8

|

||||

|

Thermal power

|

0.12mw

|

0.24mw

|

0.35mw

|

0.48mw

|

0.7mw

|

1.05MW

|

1.4MW

|

2.1MW

|

2.8MW

|

||||

|

Calorific value(kcal)

|

100,000

|

200,000

|

300,000

|

400,000

|

600,000

|

900,000

|

1200,000

|

1800,000

|

2400,000

|

||||

|

exhaust caliber

|

Φ159

|

Φ159

|

Φ159

|

Φ159

|

Φ273

|

Φ273

|

Φ320

|

Φ320

|

Φ273*2

|

||||

|

Inlet/outlet temp

|

85/65℃

|

|

|

|

|

|

|

|

|

||||

|

Inlet/outlet diameter

|

DN50

|

DN65

|

DN80

|

DN80

|

DN100

|

DN100

|

DN100

|

DN150

|

DN150

|

||||

|

fuel consumption(kg/h)

|

24

|

46

|

70

|

95

|

140

|

220

|

290

|

420

|

560

|

||||

|

Size

|

1700*650*1650

|

2100*800*1800

|

2400*950*2030

|

2600*900*1200

|

3000*1260*2400

|

3100*1260*2550

|

3100*1350*2550

|

3200*2400*2550

|

3300*2600*2600

|

||||

|

Weight

|

0.65T

|

1.1T

|

1.5T

|

1.7T

|

2.5T

|

3.9T

|

4T

|

7T

|

9.1T

|

||||

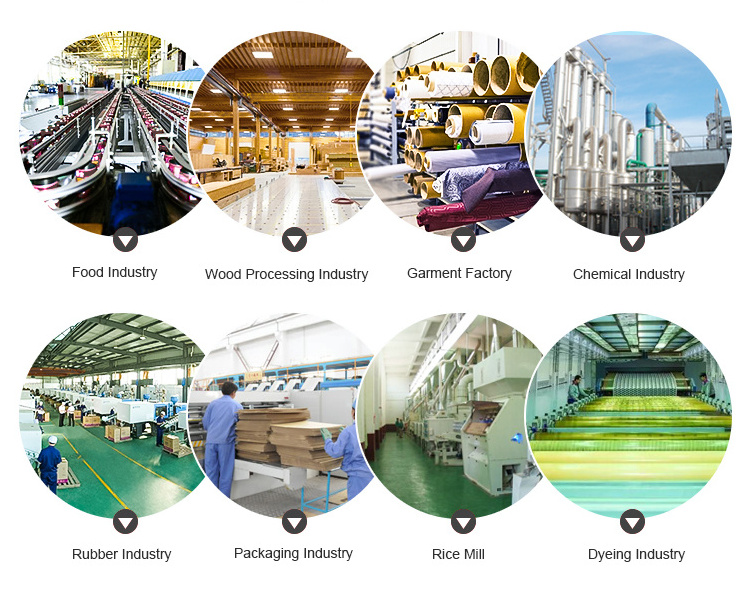

Application

Related Products

Packing&Shipping

Hot Searches