- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DEMA

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

4400*1000*2300 mm

-

Power (kW):

-

55

-

Weight:

-

3500 KG

-

Screw Type:

-

Modular / Segment

-

Self-cleaning Function:

-

Excellent

-

Automatic Grade:

-

Semi-automatic

-

Machine Painting:

-

Customized

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

40:1, 44:1

-

Screw diameter (mm):

-

51.4

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DEMA

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

4400*1000*2300 mm

-

Power (kW):

-

55

-

Weight:

-

3500 KG

-

Screw Type:

-

Modular / Segment

-

Self-cleaning Function:

-

Excellent

-

Automatic Grade:

-

Semi-automatic

-

Machine Painting:

-

Customized

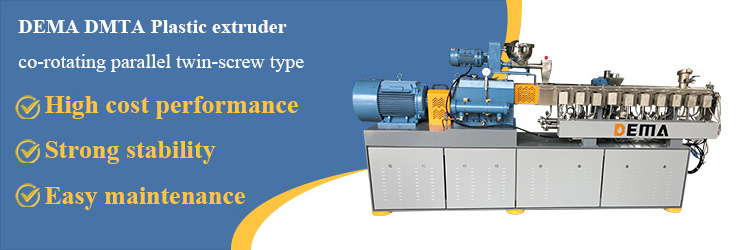

Product Paramenters

|

Model

|

Screw dia.

(mm)

|

L/D

|

Main power

(kw)

|

Screw speed

(rpm)

|

Capacity

(kg/h)

|

|

DMTA35

|

35.6

|

40-44

|

18.5

|

600

|

30-50

|

|

DMTA40

|

41.1

|

40-44

|

30

|

600

|

50-100

|

|

DMTA52

|

51.4

|

40-44

|

55

|

600

|

150-250

|

|

DMTA65

|

62.4

|

40-44

|

90/110

|

600

|

250-350

|

|

DMTA75

|

71

|

40-44

|

132/160

|

600

|

350-500

|

Products Description

DMTA / DMTH series extrusion line is mainly used for engineering plastics in compounding field. It can be used for

coloring,filling,alloy blending and other function modification of polymer such as ABS, PMMA, PEEK, PC, etc.

This is one of competitive products in DEMA with advantages of mature technology, stable performance, flexible operation, wide

range of applications etc.

This is one of competitive products in DEMA with advantages of mature technology, stable performance, flexible operation, wide

range of applications etc.

Features:

1.Screw components is completely self-cleaning type, with uniformed screw clearance and excellent mixing effect, can process

all kinds of polymer.

2.The flow channel of barrel is with special design of multi-channel, which can enhance the heat transfer capacity effectively

and improve the accuracy of the temperature control.

3.According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational solution.

all kinds of polymer.

2.The flow channel of barrel is with special design of multi-channel, which can enhance the heat transfer capacity effectively

and improve the accuracy of the temperature control.

3.According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational solution.

Material Process

Water cooling strand pelletizing line is suitable for the granulation of almost all kinds of common thermoplastic engineering

plastics and modification engineering plastics, such as ABS, PA, PC, PE, PET, POM, PP, PPS, PS, etc., including glass fiber

reinforced and inorganic filling thermoplastic extrusion.

plastics and modification engineering plastics, such as ABS, PA, PC, PE, PET, POM, PP, PPS, PS, etc., including glass fiber

reinforced and inorganic filling thermoplastic extrusion.

We can supply other different pelletizing system based on various raw materials and capacity requirements, which include water-ring hot-face pelletizing line, air cooling hot-face pelletizing line, underwater pelletizing line,etc.

Applications

We can customize solutions of granulating extruders and compounding system based on the different material and formula.Welcome to contact us for further discussion if you can’t find your application in below typical industry.

Hot Searches