- Product Details

- {{item.text}}

Quick Details

-

Power:

-

TBD

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 KG

-

Marketing Type:

-

Hot Product 2022

-

Product Name:

-

3500L Brewery Equipment

-

Application:

-

Industrial Commercial Brewery

-

Function:

-

Beer Brewing

-

Material:

-

SUS304/SUS316/Copper

-

Keywords:

-

35HL Beer Brewing Equipment

-

Capacity:

-

3500L

-

Heating method:

-

Steam Heating

-

Control system:

-

Semi/Auto Control

-

Type:

-

Complete Brewery System

-

Insulation:

-

TH=80mm with environmental protection rock wool

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TIANTAI

-

Voltage:

-

220v or customized

-

Power:

-

TBD

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 KG

-

Marketing Type:

-

Hot Product 2022

-

Product Name:

-

3500L Brewery Equipment

-

Application:

-

Industrial Commercial Brewery

-

Function:

-

Beer Brewing

-

Material:

-

SUS304/SUS316/Copper

-

Keywords:

-

35HL Beer Brewing Equipment

-

Capacity:

-

3500L

-

Heating method:

-

Steam Heating

-

Control system:

-

Semi/Auto Control

-

Type:

-

Complete Brewery System

-

Insulation:

-

TH=80mm with environmental protection rock wool

Welcome to visit Tiantai Brewery Equipment product details!

Here is our 3500l brewery system introduced to you in below, any other interested information just feel free to chat with us, our team is ready to assist any way possible!

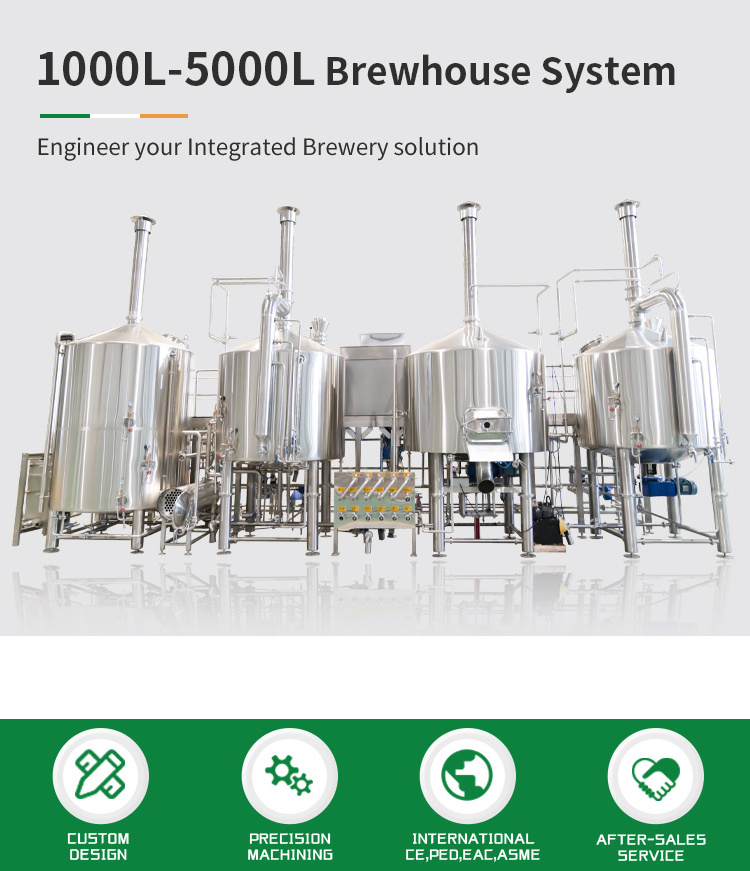

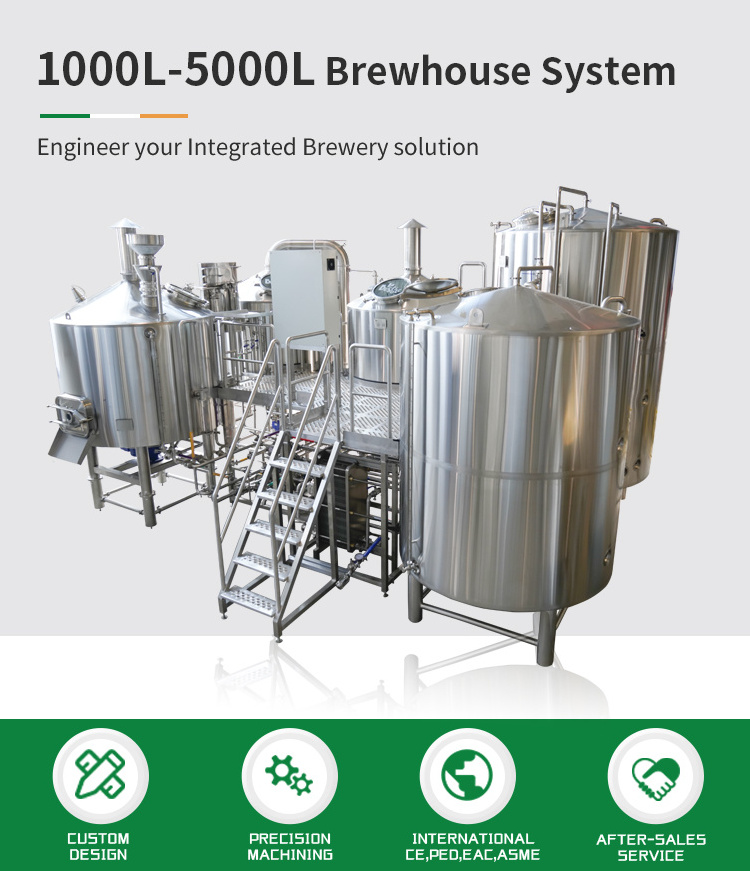

Tiantai 3500L/35HL Brewery Product:

Main Configurations Included in the Standard 3500L Brewery System:

| Part 1: Malt Milling Unit | |||

| 1.1 Malt Miller [1000~1200kg/hr] | 1set | ||

| 1.2 Flexible Auger | 1set | ||

| 1.3 1800L Grist Silo | 1set | ||

| 1.4 Milling Controling Cabinet | 1set | ||

| Part 2: 30HL Brewhouse | |||

| 2.1 35HL Mash Tun | 1set | ||

| 2.2 35HL Lauter Tun | 1set | ||

| 2.3 35HL Kettle Tun | 1set | ||

| 2.4 35HL Whirlpool Tun | |||

| 2.5 60HL Hot Water Tank | 1set | ||

| 2.6 Non-slip Work Plateform | 1set | ||

| 2.7 Sanitary Centrifugal Pump [LYSF] | 3sets | ||

| 2.8 Sanitary Piping | 1set | ||

| 2.9 Valves and Fittings | 1set | ||

| 2.10 Manual Water Mixing Station | 1set | ||

| 2.11 Manual Wort Cooling Station | 1set | ||

| 2.12 Pipeline Instrument Sensor | 0unit | ||

| 2.13 Wort Balance Column | 1set | ||

| 2.14 30M2 Heat Exchanger [304SS NANHUA] | 1set | ||

| 2.15 Pipe Filter | 1set | ||

| 2.16 Wort Aeration Station | 1set | ||

| 2.17 50L Yeast Feeder | 1set | ||

| Part 3: Fermentation Unit | |||

| 3.1 7000L Fermentation Tank/Unitank | 4sets | ||

| 3.2 7000L Bright Beer Tank | 1set | ||

| Part 4: Glycol Cooling Unit | |||

| 4.1 3500L Glycol Water Tank | 1set | ||

| 4.2 7000L Cold Liquor Tank | 1set | ||

| 4.3 12HP Glycol Water Chiller | 2sets | ||

| 4.4 Glycol Water Pipeline | 1unit | ||

| Part 5: Electric Control Unit | |||

| 5.1 Brewhouse Control Cabinet | 1set | ||

| 5.2 Fermentation Control Cabinet | 1set | ||

| Part 6: 300L Fixed CIP Unit [Two Tanks] | |||

| 6.1 300L Single Wall Caustic Tank | 1set | ||

| 6.2 300L Single Wall Acid Tank | 1set | ||

| 6.3 Sanitary Centrifugal Pump | 1set | ||

| 6.4 Sanitary Piping | 1set | ||

| 6.5 Valves and Fittings | 1set | ||

| 6.6 CIP Controling Cabinet | 1set | ||

| Part 7: Spare Parts & Tools | |||

| 7.1 Spare Parts for brewhouse | 1set | ||

| 7.2 Spare Parts for fermentation | 1set | ||

| 7.3 Spare Parts for control | 1set | ||

| 7.4 Spare Parts for CIP | 1set | ||

| 7.5 Standard Installation Tools | 1set | ||

Tanks Dimensions References:

WHY TIANTAI?